Novel combined cutter bar

A combined type and tool holder technology, which is applied to the accessories of tool holders, turning equipment, metal processing equipment, etc., can solve the problems of inconvenient loading and unloading of the heat-shrinkable tool holder 100, and difficulty in taking out the tool 200, etc., to achieve enhanced rigidity and matching Stabilizing, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

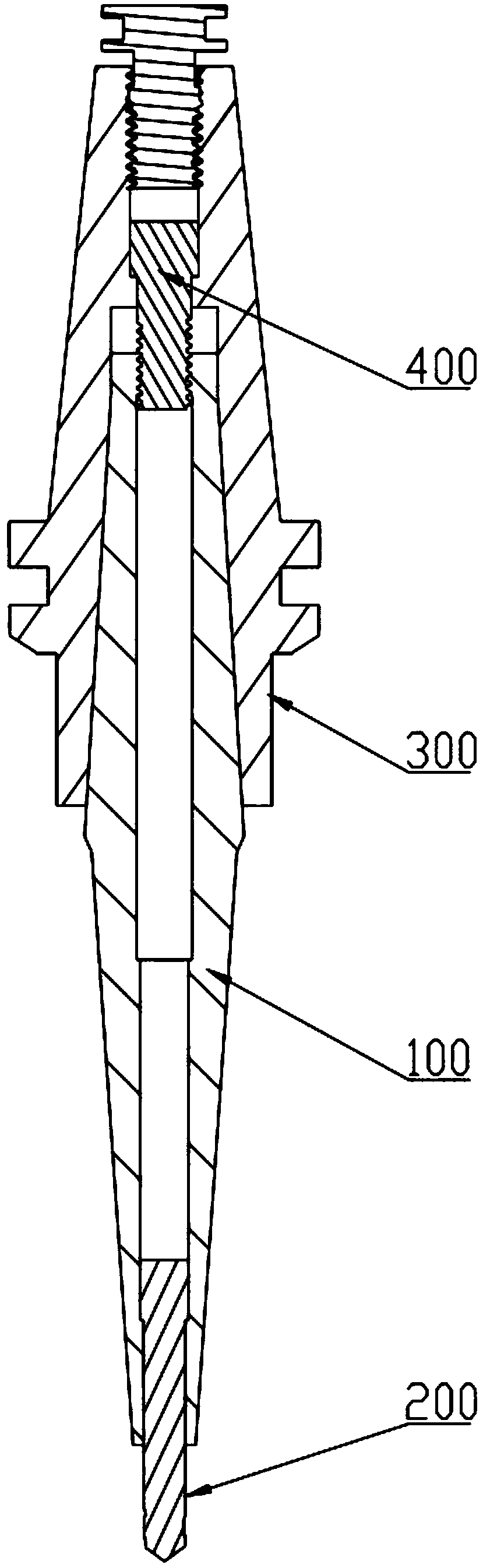

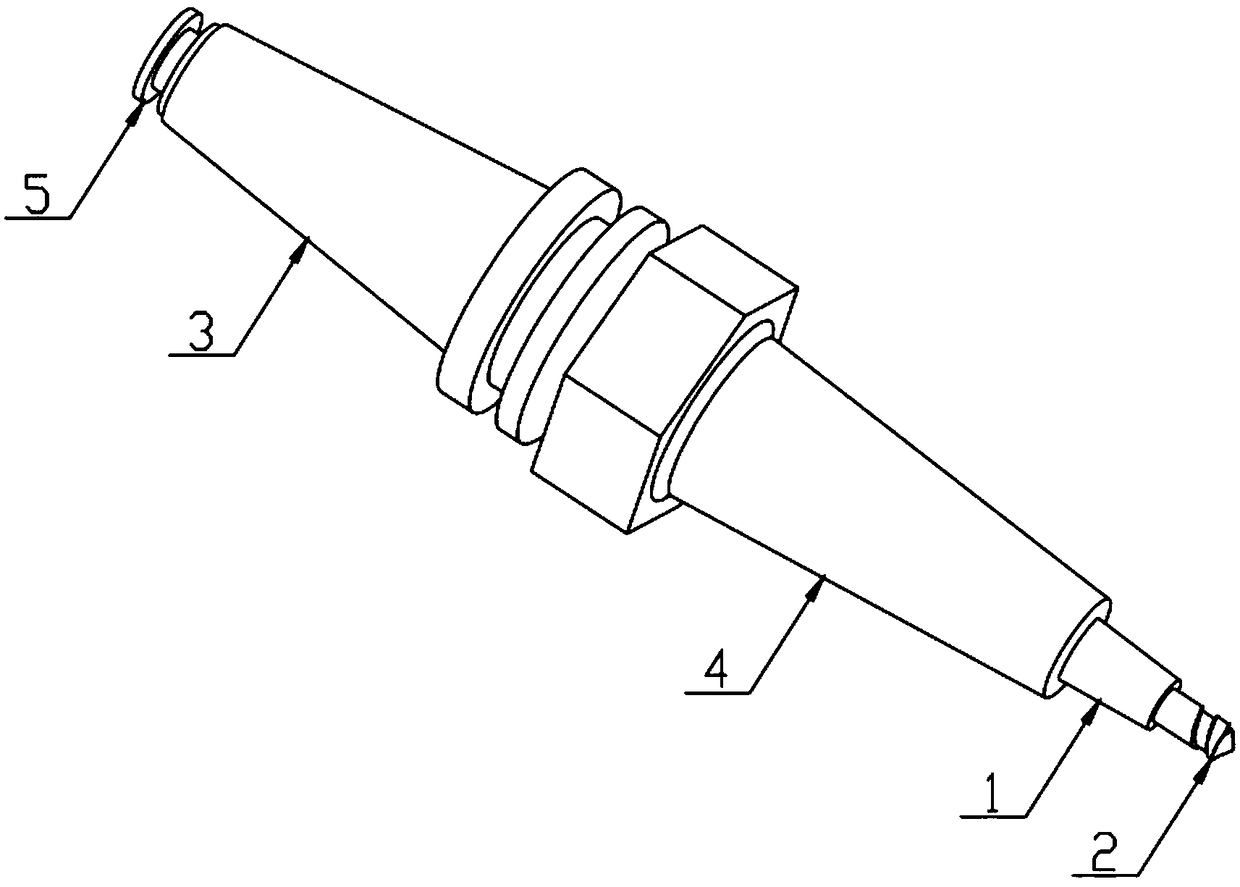

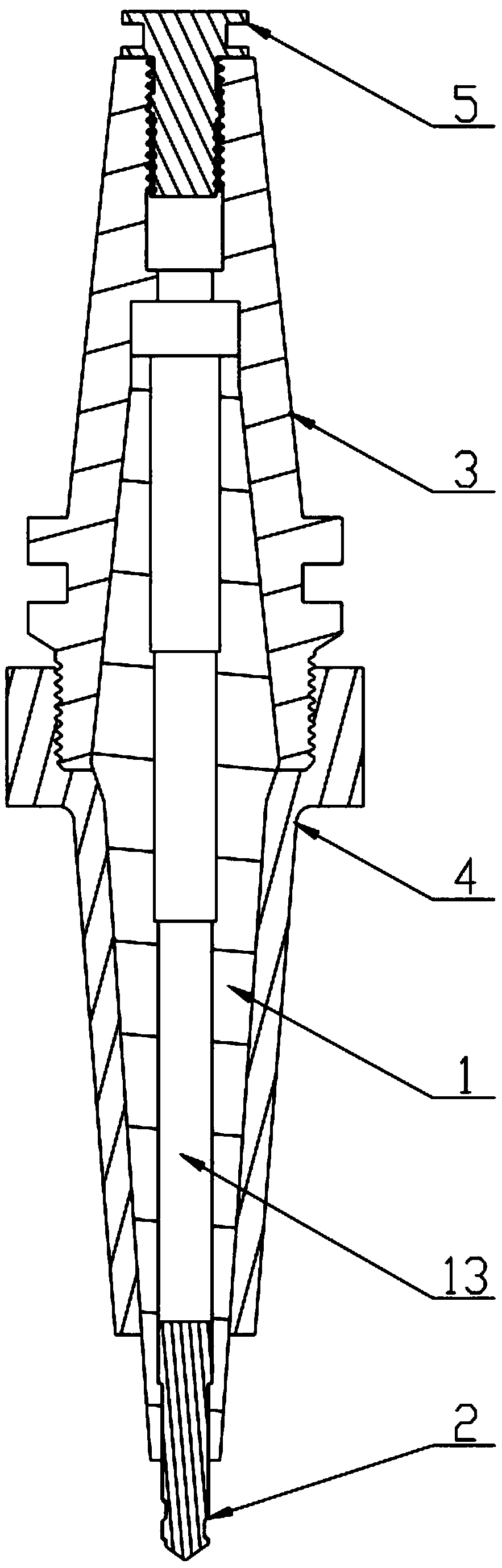

[0029] Such as Figure 2-5 As shown, the novel combined tool holder of this embodiment includes a heat shrinkable tool holder 1, a tool 2, a handle 3 and a sleeve 4; one end of the heat shrinkable cutter holder 1 is provided with a first tapered surface 11, and the other end is provided with a There is a second tapered surface 12, and a through hole 13 is opened inside along the axial direction; one end of the tool 2 is inserted into the through hole 13 through shrink fit, and the other end extends out of the through hole 13; the handle 3 The inside of the sleeve 4 is provided with a first tapered hole 31 matched with the first tapered surface 11, and is sleeved on the first tapered surface 11 through the first tapered hole 31; the inside of the sleeve 4 is provided with a second The second tapered hole 41 matched with the tapered surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com