Drilling jig used for machining U-shaped plate through hole

A technology of plate through-hole and drilling mold, which is applied in the direction of boring/drilling, metal processing equipment, drilling/drilling equipment, etc., which can solve the problems of high roughness and concentricity of through-holes, and reduce smoke and dust. The effect of avoiding and avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

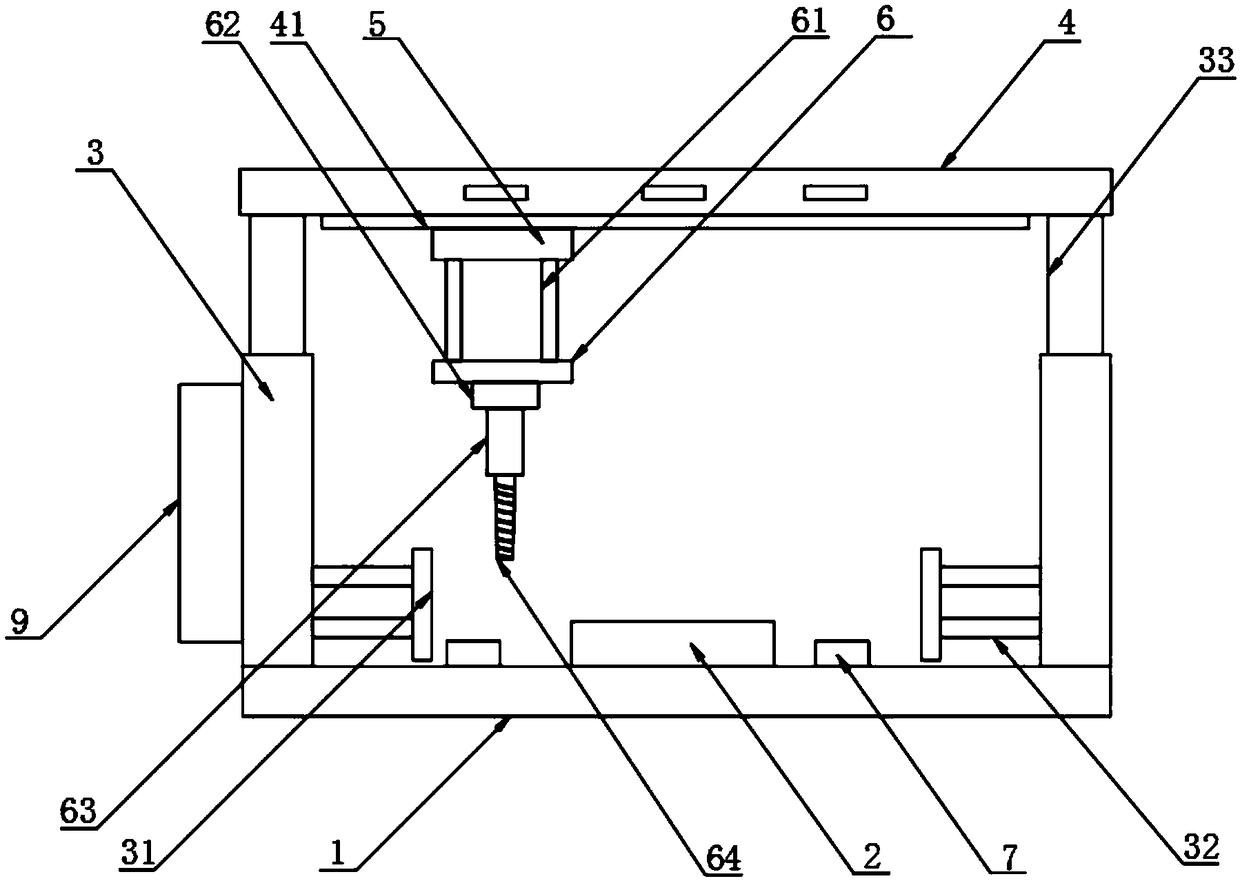

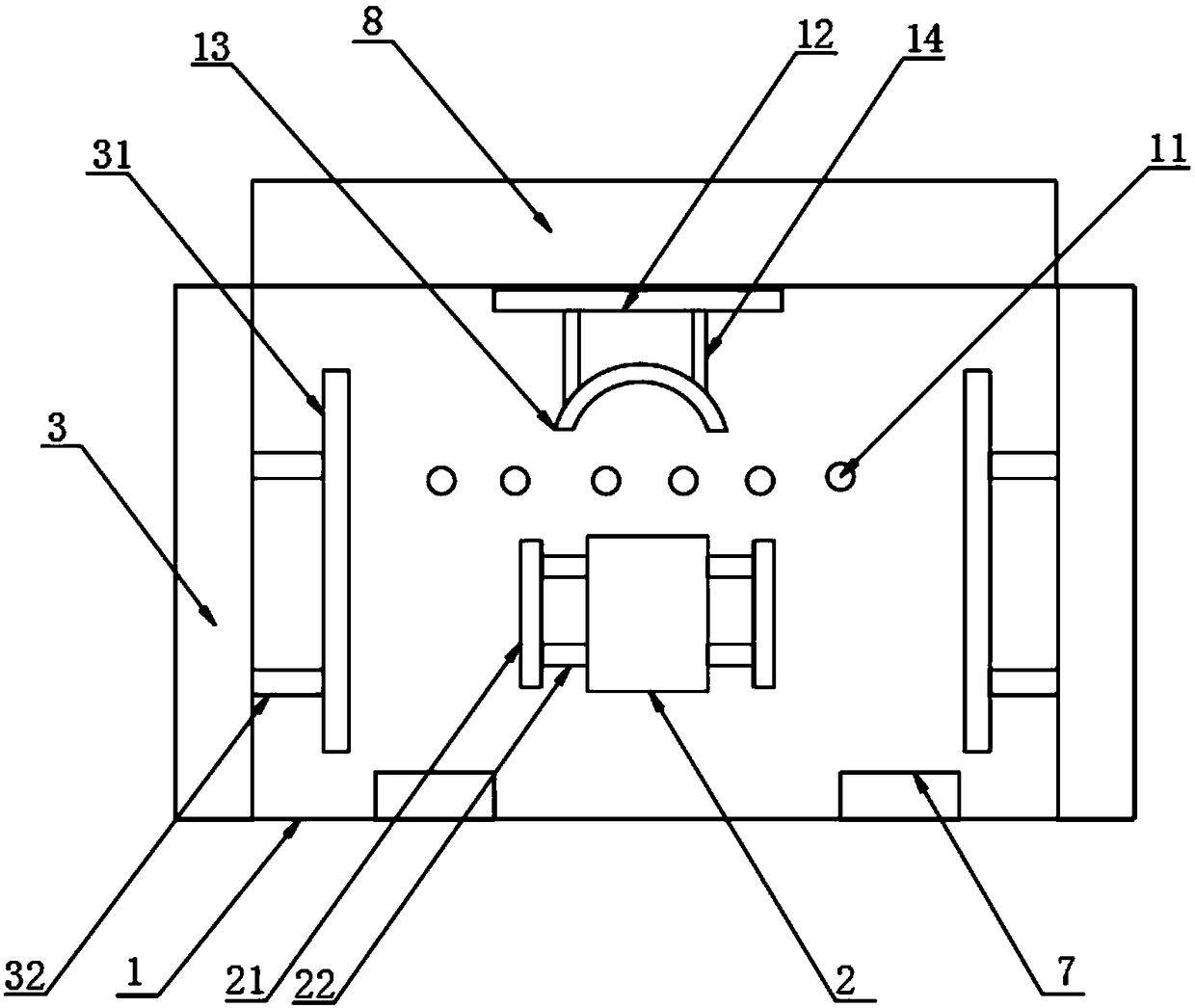

[0023] The present invention provides such Figure 1-4 A kind of drilling mold that is used for U-shaped plate through-hole processing as shown, comprises processing base 1, and described processing base 1 top surface is provided with fixing plate 2, and described processing base 1 top both ends are all provided with column 3, so The top of the column 3 is provided with a top plate 4, the bottom of the top plate 4 is provided with a walking housing 5, and the bottom of the walking housing 5 is provided with a lifting plate 6, and a second plate is evenly arranged between the lifting plate 6 and the walking housing 5 Two hydraulic lifting rods 61, the bottom of the lifting plate 6 is fixed with a motor 62, the bottom of the motor 62 is provided with a transmission shaft 63, the transmission shaft 63 is connected with the motor 62, and the bottom of the transmission shaft 63 is screwed with a drill A hole shaft 64, a blower 7 is provided on the top of the processing base 1, and ...

Embodiment 2

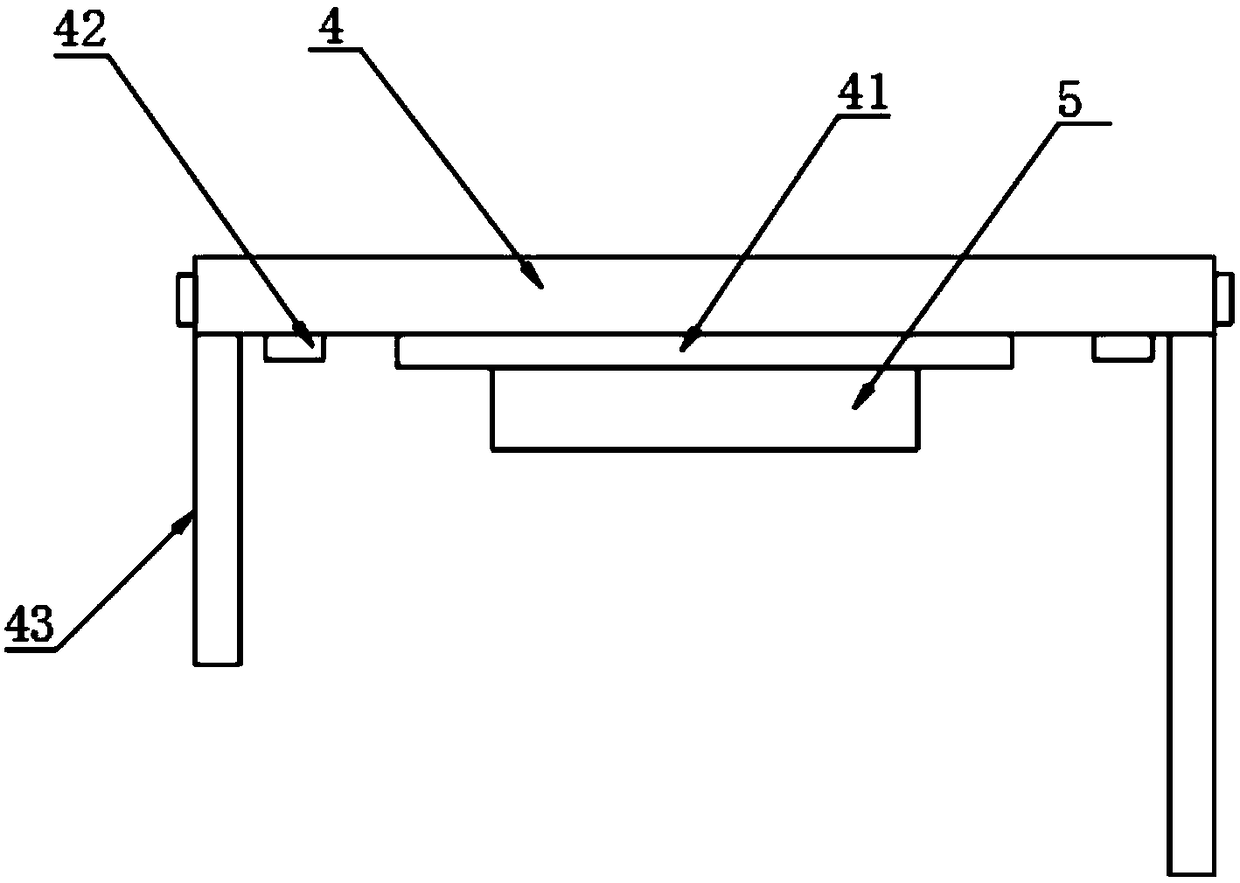

[0029] The bottom of the top plate 4 is provided with guide rails 41 , the front and rear sides of the top plate 4 and both sides of the guide rail 41 are uniformly provided with laser sensors 42 , and the bottoms of both ends of the top plate 4 are provided with protective plates 43 .

[0030] The walking housing 5 is clamped and arranged inside the guide rail 41, the inside of the walking housing 5 is provided with a traveling motor, and the connection between the walking housing 5 and the guide rail 41 is provided with a plurality of traveling wheels, and the traveling wheels pass through the transmission The gear is connected with the driving motor transmission.

[0031] Beneficial effects of this embodiment: the laser sensor 42 detects the position of the U-shaped plate and the position of the required punching and transmits the detection data to the control device 9. The internal travel motor of the control device 9 travels the housing 5 and can drive the travel housing 5...

Embodiment 3

[0033] The shape of the baffle plate 8 is set as an arc, and the bottom of the baffle plate 8 is fixedly provided with an ash storage tank 81, and the connection between the baffle plate 8 and the ash storage tank 81 is provided with a first through hole 82. A second through hole 83 is provided inside the board 8 , and the second through hole 83 is matched with the protection board 43 .

[0034] The outside of the column 3 is provided with a control device 9, the surface of the control device 9 is provided with a touch screen, and the inside of the control device 9 is provided with a PLC controller, a wireless data transmission module, a data processing module and a data receiving module. The control device 9 is connected with the blower 7 through a transmission cable.

[0035] Beneficial effects of this embodiment: During the processing, the protective plate 43 at the bottom of the top plate 4 is respectively inserted into the second through hole 83 and outside the processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com