Special Y-cone granulating machine for ceramic/metal powder

A metal powder and granulator technology, which is applied in the field of metal granulation equipment and ceramics, can solve the problems of easy pollution, high labor cost, dust pollution, etc., and achieve the effect of improving dust pollution, high degree of automation, and avoiding dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

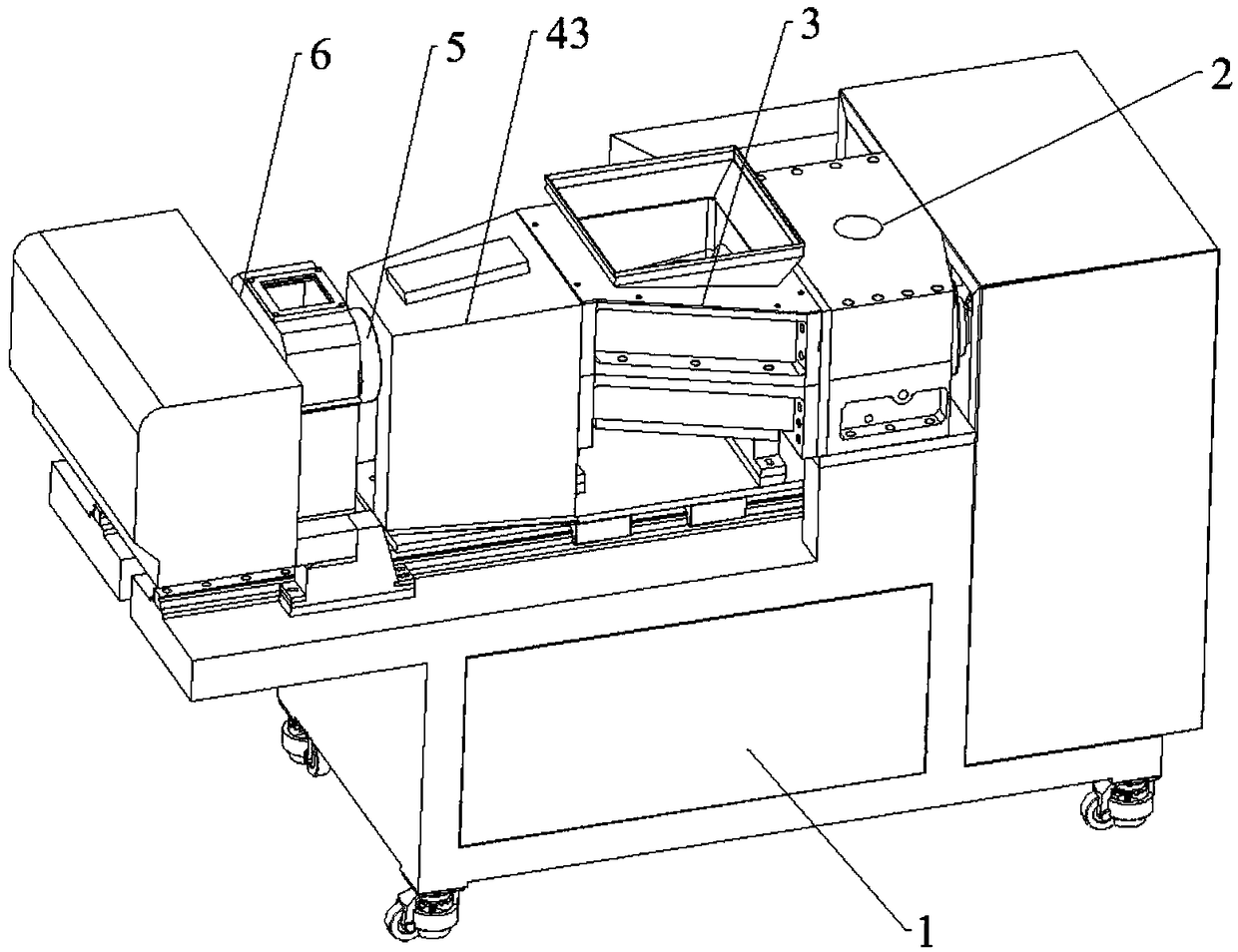

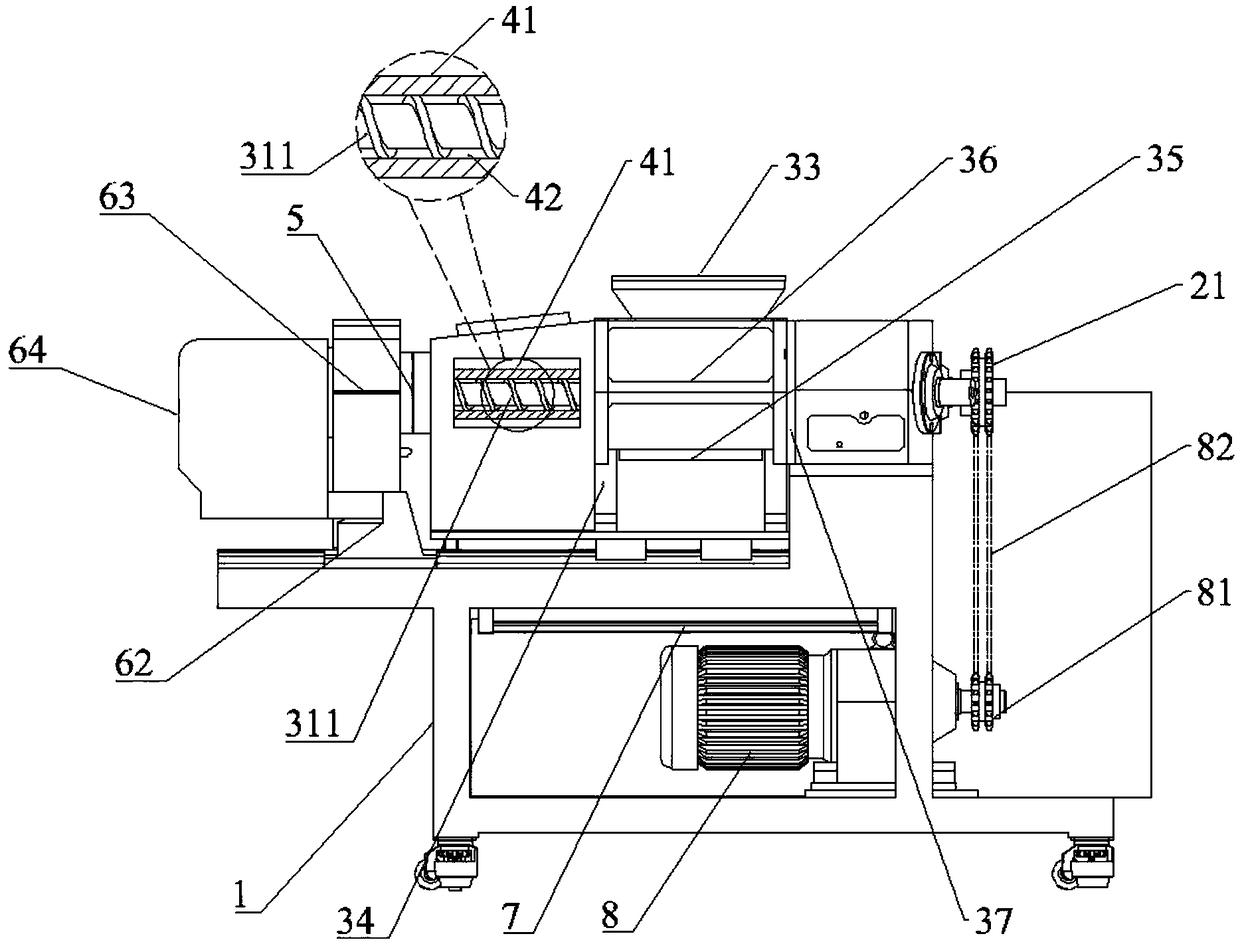

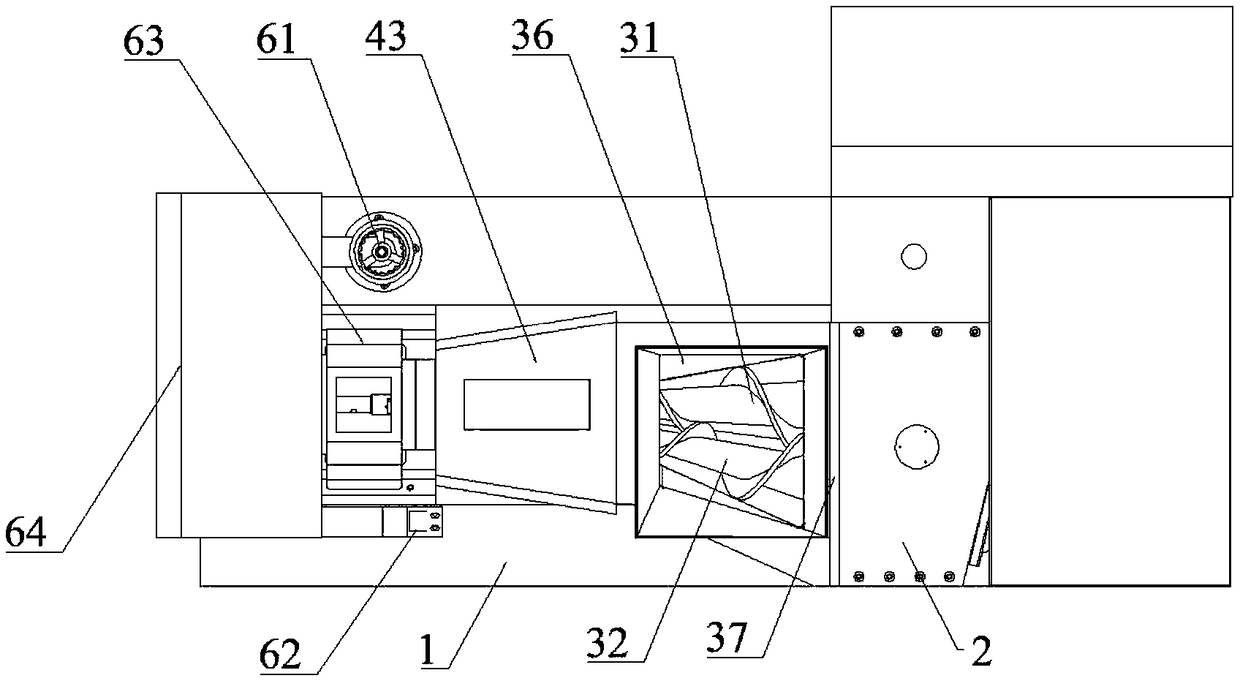

[0022] The special Y cone granulator for ceramic / metal powder includes a frame 1, the upper end of the frame 1 is equipped with a heating barrel 41 arranged horizontally and horizontally, and the outer surface of the heating barrel 41 is covered with an electric heater. The inside of the heating barrel 41 forms a melt extrusion chamber 42 extending along the axial direction of the heating barrel 41. The front end of the heating barrel 41 is equipped with an extruder head 5, and the upper end of the frame 1 is used for heating. The rear end of the barrel 41 is connected to the double-cone cavity 3 .

[0023] Further, the double-cone cavity 3 includes a double-cone tank 36 and a tank support seat 34 installed on the lower end side of the double-cone tank 36, the lower end of the tank support seat 34 is screwed to the frame 1, and the double-cone The inside of the tank body 36 has a main screw rod 31 and a secondary screw rod 32 that completely penetrate the front and back. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com