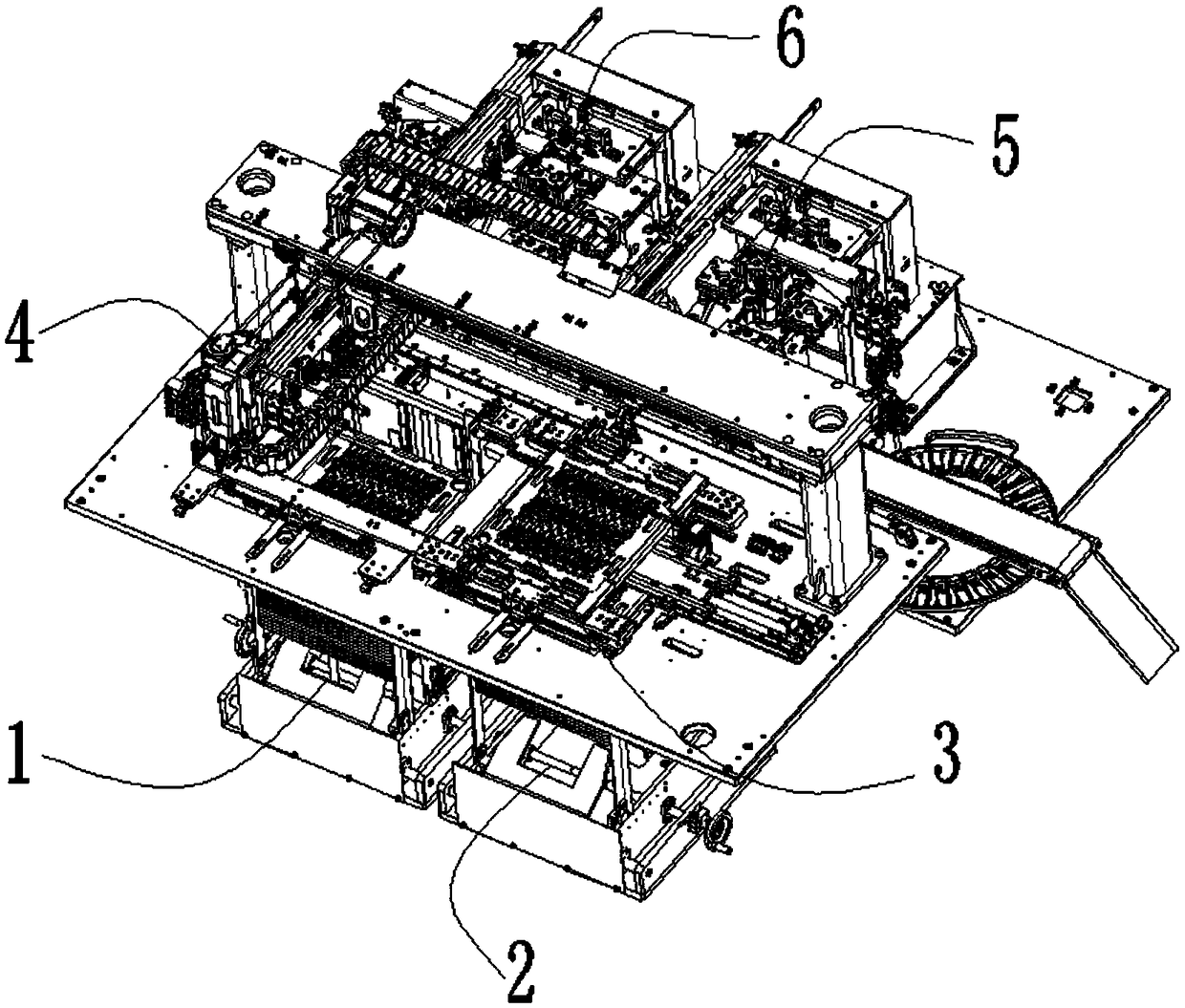

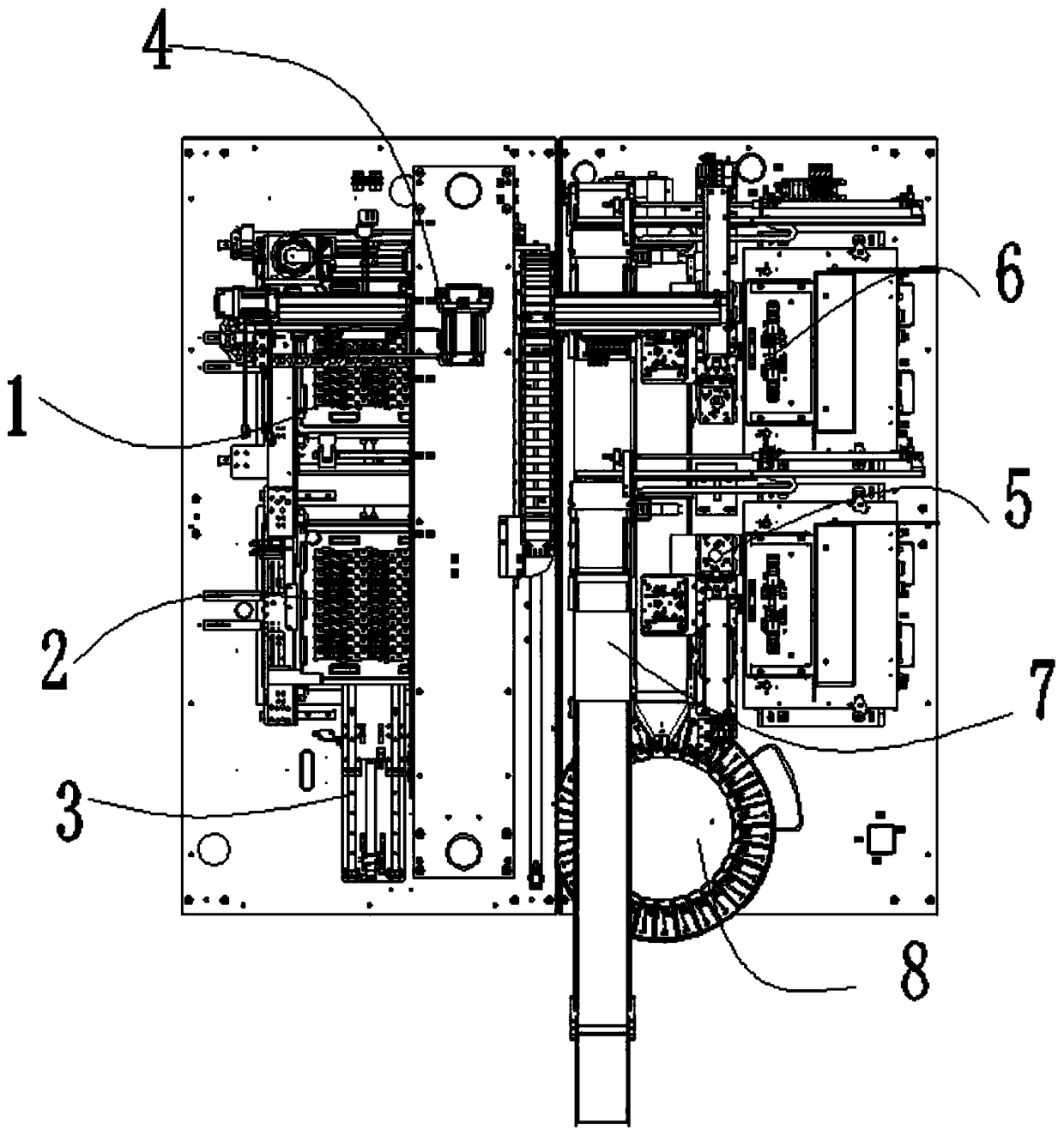

Full-automatic feeding and discharging testing equipment

A testing equipment, loading and unloading technology, applied in conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as poor test quality stability, high labor costs, product damage, etc., to reduce labor costs and improve production efficiency. , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The transport mechanism includes an X-axis driving unit 43, a Y-axis driving unit 41 and a grabbing unit, and the X-axis driving unit 43 is installed on the movable end of the Y-axis driving unit 41; Seat 45, grabbing rotating motor 46 and grabbing structure 47, described grabbing mount 45 is fixed on the movable end of described X-axis driving unit 43, and described grabbing rotating motor 46 is installed in described grabbing mount 45 Above, the grabbing structure 47 is fixed on the output end of the grabbing rotating motor, and there are multiple grabbing structures. It should be noted that, in order to better control the rotation angle of the grab rotary motor, a position sensor (not shown in the figure) is provided on the grab mount; The number of groups is correspondingly set, but in order to simplify the process, reduce equipment investment costs and improve production efficiency, the transmission direction of the transmission line mechanism is provided with two ...

Embodiment 2

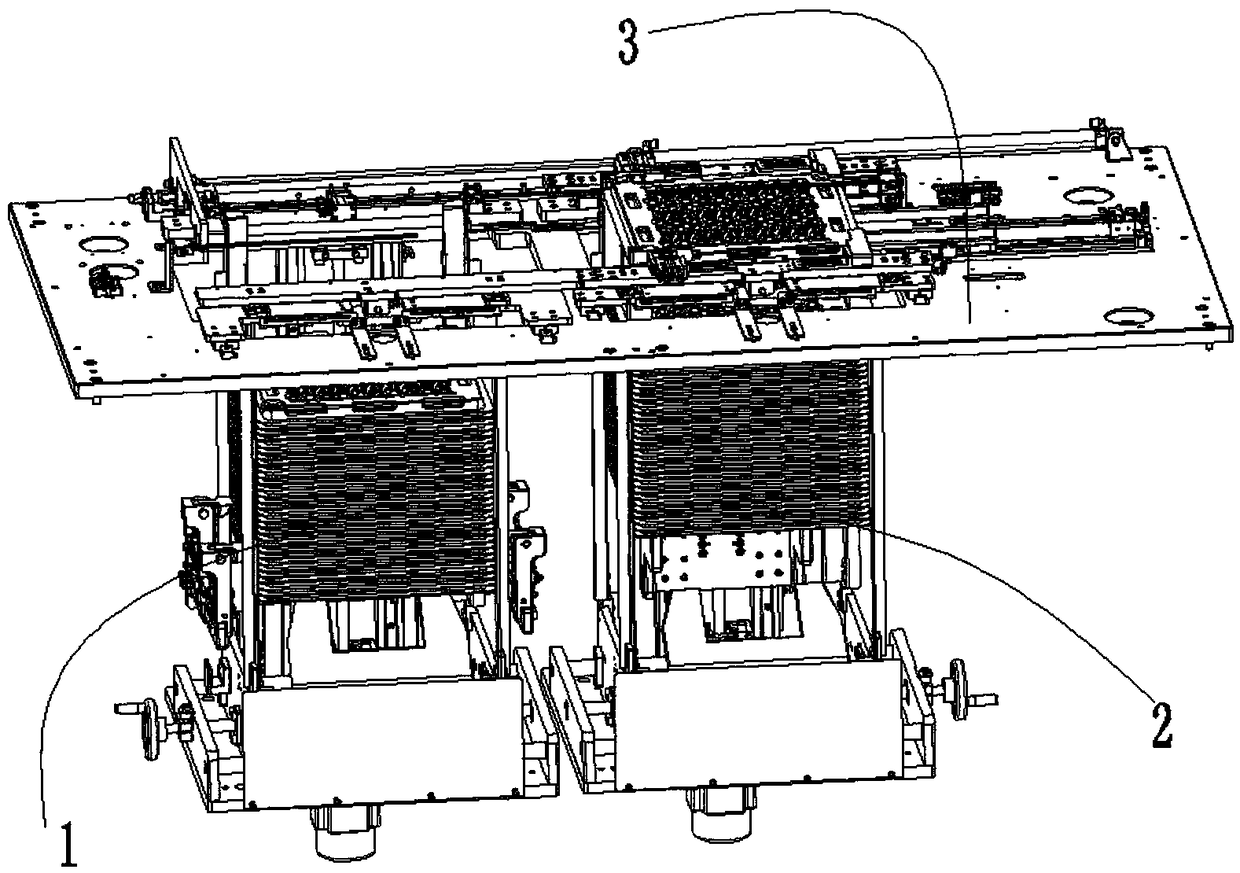

[0049] The feeding mechanism includes a receiving unit 2, a feeding unit 1 and a tray handling unit 3; the tray handling unit 3 includes a tray handling base 30 and a tray limiting structure, and the tray limiting structure includes a feeding tray The limiting structure of the material tray and the limiting structure of the receiving tray; the limiting structure of the feeding tray includes a material limiting slide rail 31 and a material limiting cylinder 313, and the material limiting cylinder 313 is fixed on the On the tray handling base 30, the loading limiting slide rail 31 is fixed on the movable end of the loading limiting cylinder 313; the limiting structure of the receiving tray includes a receiving limiting cylinder 387, a receiving Material limit slide rail 38, the material receiving limit cylinder 387 is fixed on the material tray handling base 30, and the material receiving limit slide rail 38 is fixed on the movable end of the material receiving limit cylinder 387...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com