Graphene material for asphalt modification and preparation method and application

A technology of asphalt modification and graphene, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of complex modification process and unfavorable industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

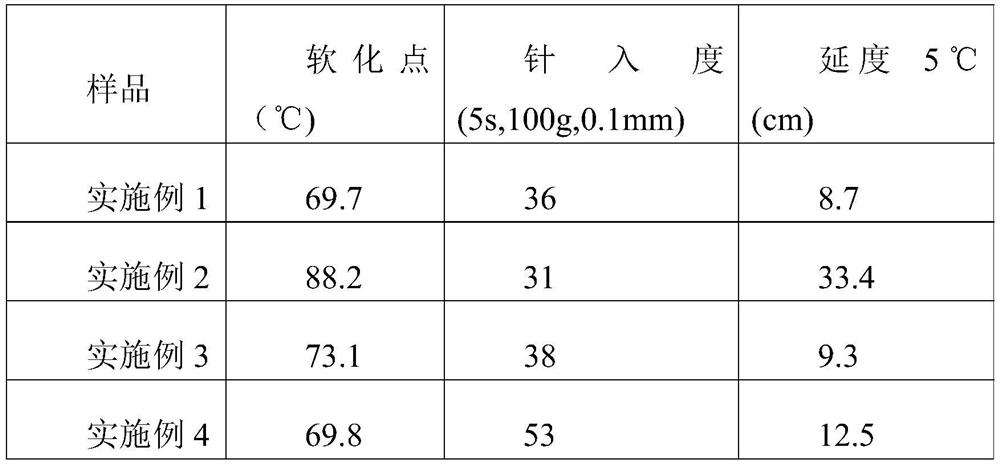

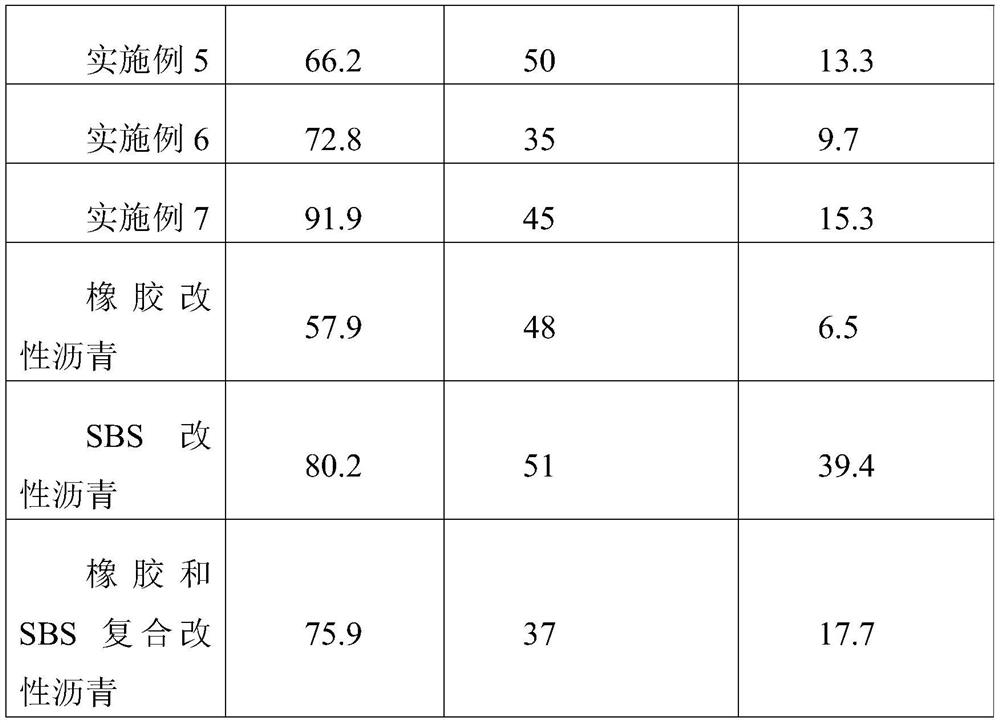

Examples

Embodiment 1

[0029] The preparation steps of the graphene material used for asphalt modification are as follows:

[0030] (1) Carrying out high-temperature oxidation of three-dimensional structure graphene at 320° C. in a tube furnace for 2 hours to obtain partially oxidized three-dimensional structure graphene;

[0031] (2) Weigh respectively isopropyl triisostearyl titanate, isopropanol and the above-mentioned partially oxidized three-dimensional graphene by the following parts by weight;

[0032] Partially oxidized three-dimensional graphene 5 parts

[0033] 0.5 parts of isopropyl triisostearyl titanate

[0034] 94.5 parts of isopropanol

[0035] (3) According to the amount of each component weighed in step (2), stir and mix isopropanol and isopropyl triisostearyl titanate for 5 minutes, and add the above-mentioned partially oxidized Stereostructured graphene, stirred at high speed for 1 hour, and dried in a blast oven at 95°C for 2 hours to obtain graphene materials for asphalt modi...

Embodiment 2

[0038] The preparation steps of the graphene material used for asphalt modification are as follows:

[0039] (1) Oxidize the graphene microchips with concentrated sulfuric acid for 1 hour and filter and wash with water and dry to obtain partially oxidized graphene microchips;

[0040] (2) Take gamma-mercaptopropylmethyldiethoxysilane, dehydrated alcohol and the above-mentioned partially oxidized graphene microchips by weighing respectively by the following parts by weight;

[0041] Partially oxidized graphene microflakes 8 parts

[0042] 0.16 parts of γ-mercaptopropylmethyldiethoxysilane

[0043] 91.84 parts of absolute ethanol

[0044] (3) According to the amount of each component weighed in step (2), stir and mix the absolute ethanol and γ-mercaptopropylmethyldiethoxysilane for 4 minutes, and add the above-mentioned part after the dispersion is uniform. The oxidized graphene microsheets were stirred at a high speed for 1.5 hours, and dried by a rotary evaporator to obtain...

Embodiment 3

[0047] The preparation steps of the graphene material used for asphalt modification are as follows:

[0048] (1) The three-dimensional structure graphene is oxidized by concentrated nitric acid for 30 minutes and then filtered and washed with water and dried to obtain partially oxidized three-dimensional structure graphene;

[0049] (2) take cetyltrimethoxysilane, butanol and the above-mentioned partially oxidized three-dimensional graphene respectively by the following parts by weight;

[0050] Partially oxidized three-dimensional graphene 12 parts

[0051] Hexadecyltrimethoxysilane 0.36 parts

[0052] Butanol 87.64 parts

[0053] (3) According to the amount of each component weighed in step (2), butanol and hexadecyltrimethoxysilane were stirred and mixed for 4 minutes, and after the dispersion was uniform, the above-mentioned partially oxidized three-dimensional graphite was added therein. Graphene, stirred at high speed for 2 hours, butanol was discarded by filtration a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com