Tar separation unit and tar separation system

A separation unit and separation system technology, applied in the field of annular tar separation unit and multi-stage tar separation system, tar separation unit and tar separation system, annular multi-stage tar separation unit and multi-stage tar separation system, can solve the problem that is difficult to adapt to large-scale Problems such as modernized projects, poor cooling effect, and large floor area, etc., to achieve the effect of improving cooling effect, reducing equipment volume, and improving cooling water utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

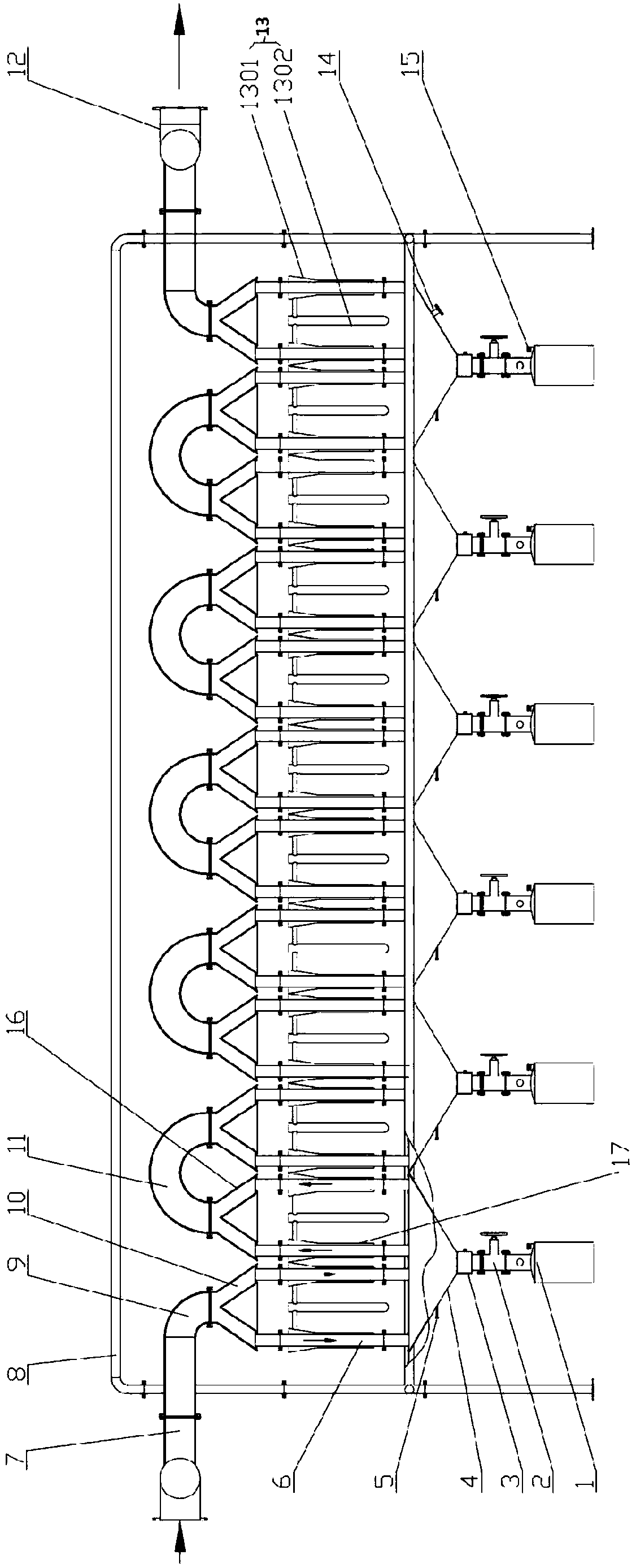

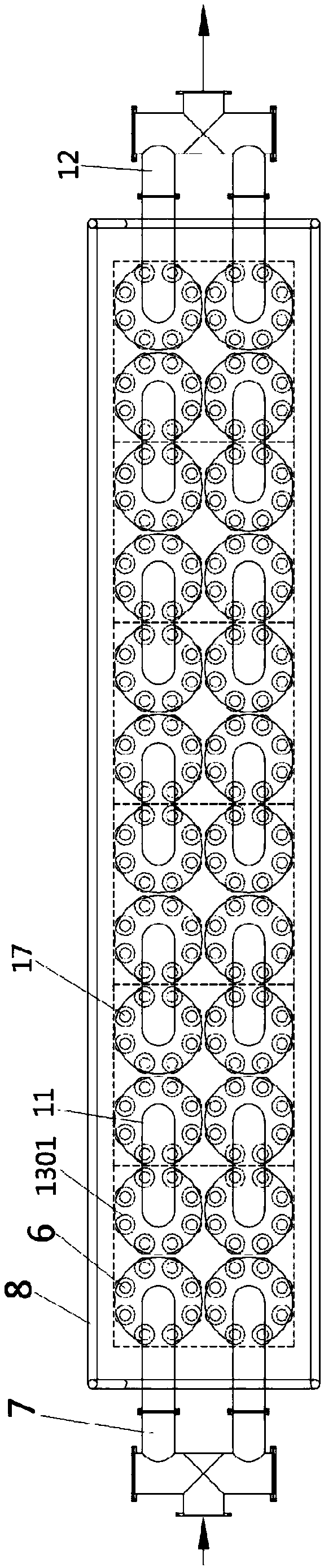

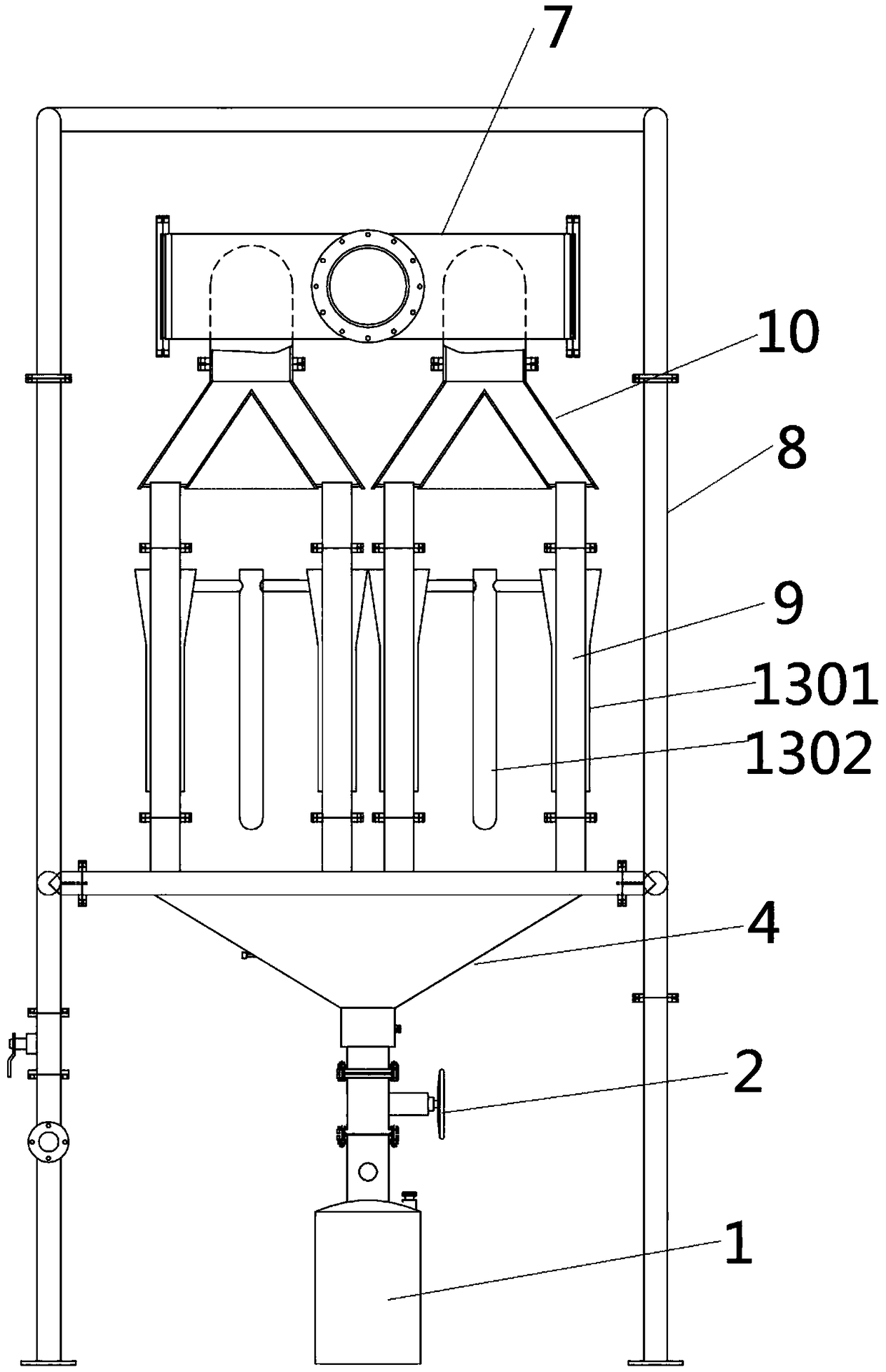

[0040] like Figure 1 to Figure 3As shown, a tar separation system includes a sequentially connected intake pipe 7, six tar separation units, and an outlet pipe 12; the tar separation unit shown includes a bucket 4, a first distributor 10 located above the bucket 4, and a second distributor 16, the first distributor 10 communicates with the bucket 4 through at least two first pipes 6, and the bucket 4 communicates with the second distributor 10 through at least two second pipes 17....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com