A kind of preparation method of chrome-free leather

A technology for chrome leather and tare weight, applied in the field of chrome-free leather preparation, can solve the problems of environmental pollution and increase the complexity of the process, and achieve the effects of reducing environmental pollution, shortening the production cycle and reducing the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

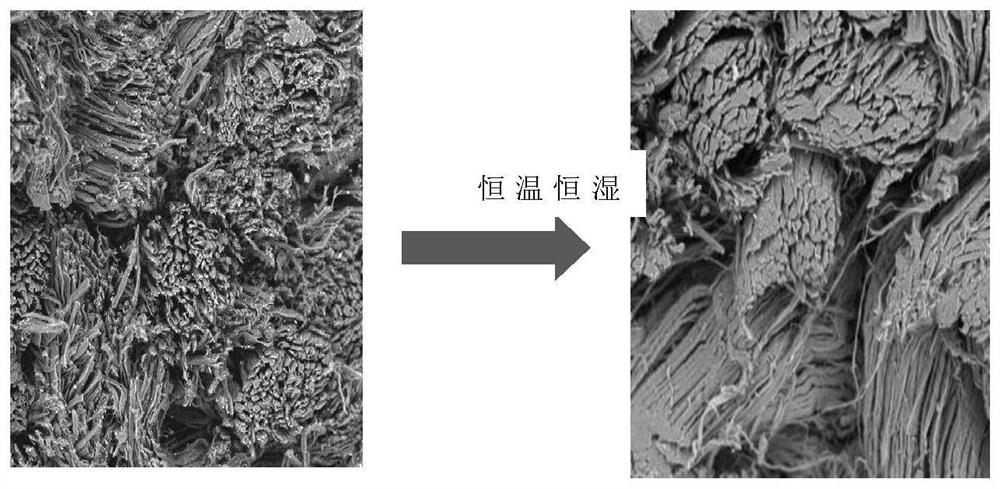

[0037](1) Solvent dehydration: first place the pickled skin in a drum, wash it with water to remove the salt, and then dehydrate the skin with a step-by-step dehydration method, that is, first use 400% absolute ethanol solution to dehydrate twice, each time 120min; Then use the mixed solution of 400% absolute ethanol and acetone (mass ratio is 1:1) to dehydrate 1 time, 120min; finally use 400% acetone solution to dehydrate 1 time, 120min, get the wet white skin with fiber dispersion at this time, recycle Organic solvents;

[0038] (2) Block the hydrophilic group: add tare 40% acetone, tare 4% IPDI trimer, rotate for 360 minutes, so that the IPDI trimer is well penetrated and reacted in the skin, and then recover the bath liquid;

[0039] (3) Drying: take out the treated leather from the drum, hang it to dry, and obtain the fiber-fixed chrome-free leather.

Embodiment 2

[0041] (1) Solvent dehydration: first place the pickled skin in a drum, wash it with water to remove the salt, and then dehydrate the skin with a step-by-step dehydration method, that is, first use 400% absolute ethanol solution to dehydrate twice, each time 120min; Then use the mixed solution of 400% absolute ethanol and acetone (mass ratio is 1:1) to dehydrate 1 time, 120min; finally use 400% acetone solution to dehydrate 1 time, 120min, get the wet white skin with fiber dispersion at this time, recycle Organic solvents;

[0042] (2) Block the hydrophilic group: add 40% tare acetone and 4% tare IPDI trimer, rotate for 360 min, and recover the bath liquid.

[0043] (3) Filling: Add 40% tare acetone and 10% tare white oil, rotate for 120min, and recover the bath liquid.

[0044] (4) Drying: The treated leather is taken out from the drum and dried in vacuum to obtain fiber-fixed chrome-free leather.

Embodiment 3

[0046] (1) Solvent dehydration: first place the softened skin in a drum, and then dehydrate the skin with a step-by-step dehydration method, that is, dehydrate with 400% absolute ethanol solution twice, each time for 120min; The mixed solution of water ethanol and acetone (mass ratio is 1:1) is dehydrated once for 120 minutes; finally, it is dehydrated once with 400% acetone solution for 120 minutes. At this time, wet white leather with fiber dispersion is obtained, and the organic solvent is recovered in each step;

[0047] (2) Block the hydrophilic group: add tare 100% acetone, tare 1.5% IPDI trimer, rotate for 60 min, then add tare 2.5% IPDI trimer, rotate for 240 min, and recover the bath liquid.

[0048] (3) Drying: The treated leather is taken out from the drum, and stretched to dry to obtain fiber-fixed chrome-free leather.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com