Device for surface treatment of fracturing pump valve box

A surface treatment and fracturing pump technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of ineffective surface treatment, etc., to achieve the advantages of drying, short passivation time, Good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

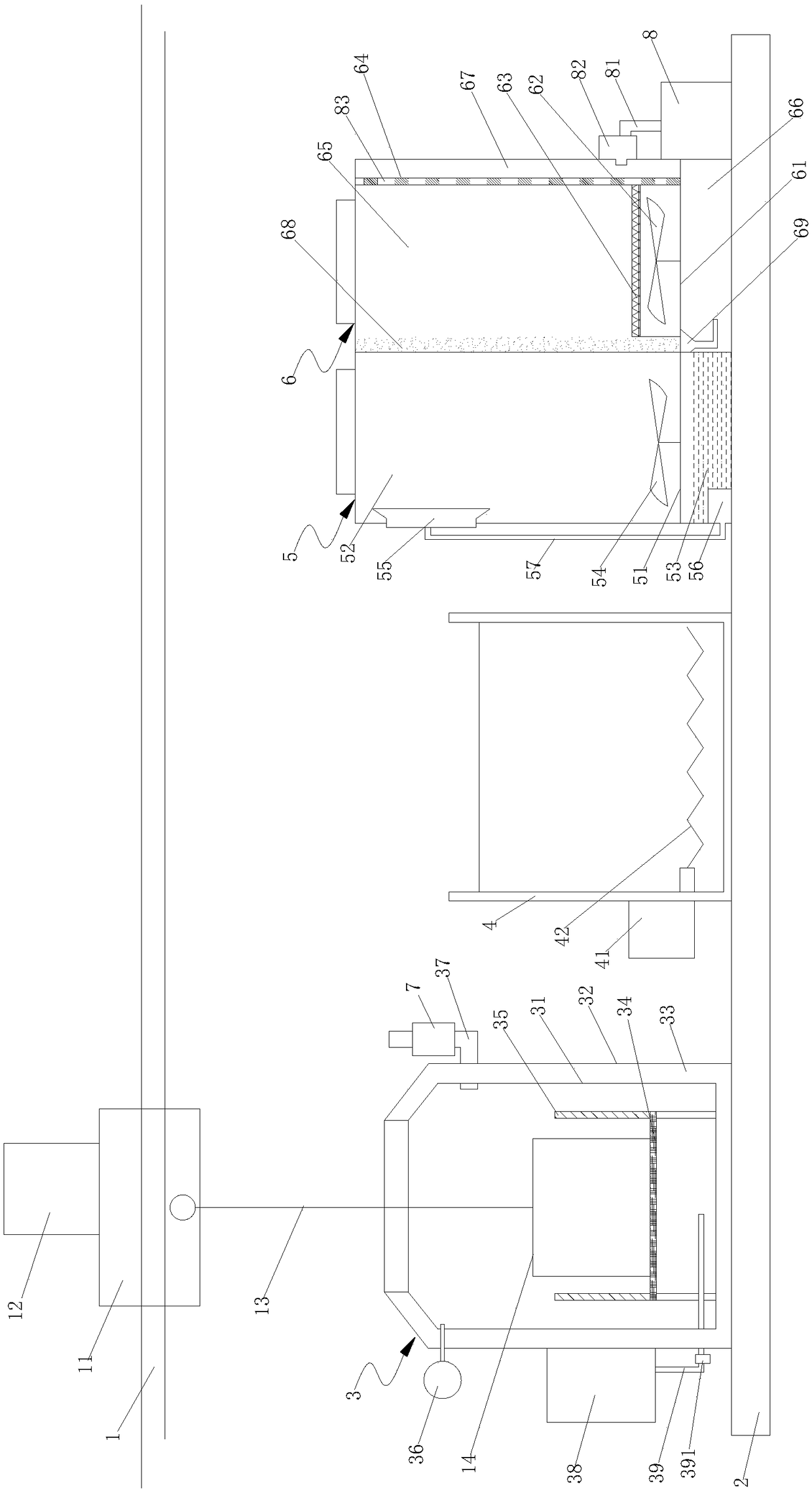

[0022] like figure 1 Shown: a device for surface treatment of the fracturing pump valve box, including a suspension rail 1 and a base 2, the suspension rail 1 is installed directly above the base 2, and the base 2 is sequentially installed with seepage Nitrogen furnace 3, phosphating pool 4, passivation cylinder 5 and drying box 6; said trolley 11 is provided with a trolley on the suspension rail 1, said trolley 11 moves on the suspension rail 1, and said trolley 11 is equipped with a motor 12 , sling 13 and frame 14, described frame 14 is connected on the lower end of sling 13, and the upper end of described sling 13 is connected on the trolley 11;

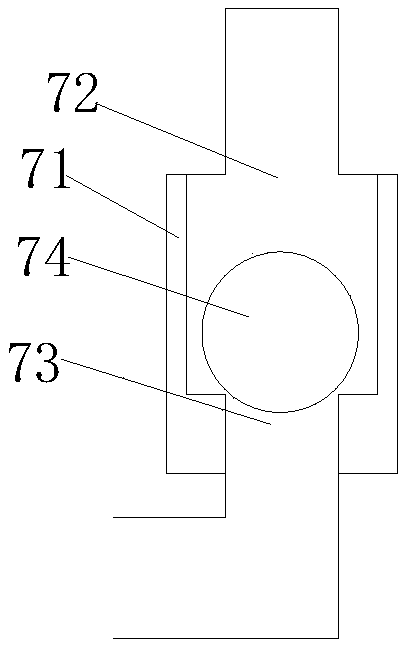

[0023] The nitriding furnace 3 includes a cylindrical inner shell 31 and an outer shell 32, a vacuum layer 33 is provided between the inner shell 31 and the outer shell 32, and a tray is arranged in the inner cavity of the inner shell 31 34. The tray 34 is in the shape of a circular grid, and the upper side of the tray 34 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com