A numerical control machining method for precision deep groove parts

A processing method and deep groove technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of dimensional accuracy and surface roughness deviation, and achieve the effects of improving service life, ensuring surface roughness, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

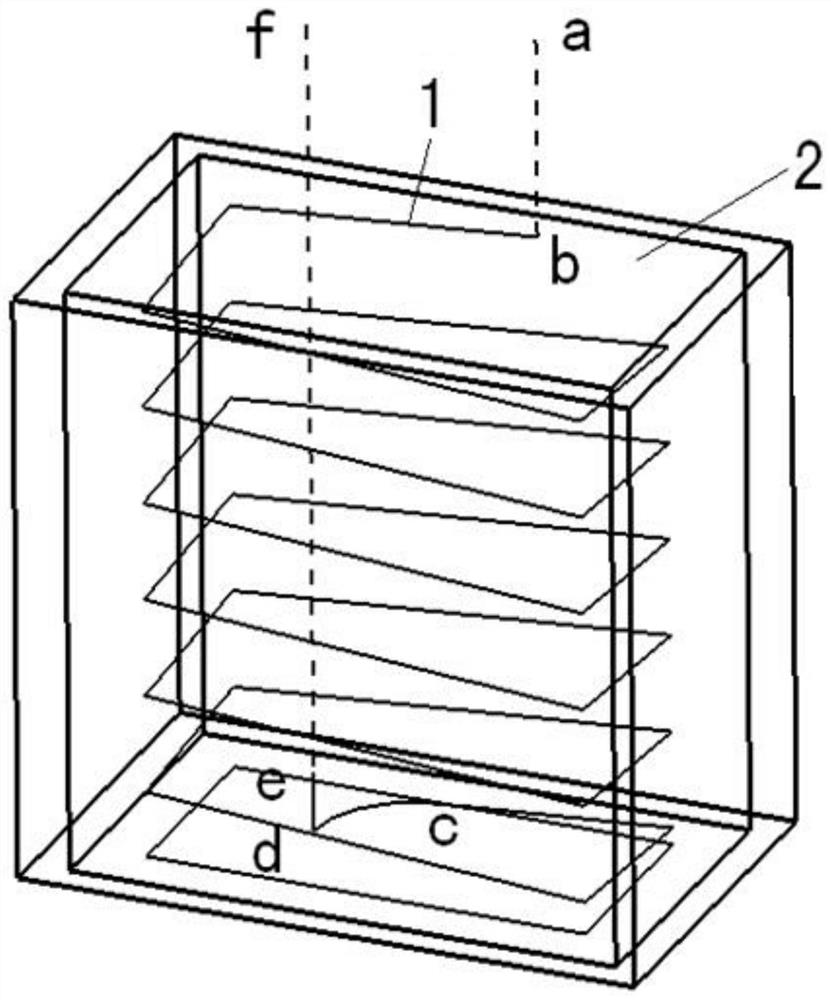

[0020] In order to deepen the understanding of the present invention, the following will be described in detail in conjunction with the accompanying drawings and specific embodiments. The embodiments described in this specification are only used to explain the present invention, and are not intended to limit the present invention.

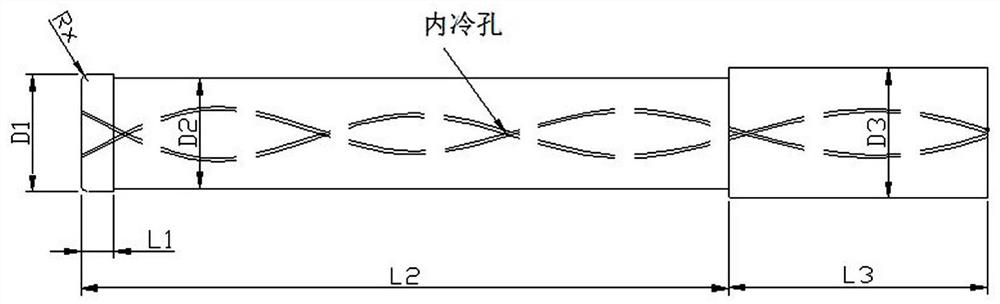

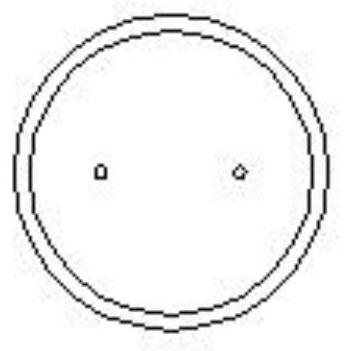

[0021] figure 2 and image 3 As shown, a kind of numerical control processing method of precision deep groove type parts of the present invention comprises the following steps:

[0022] (1) Use a horizontal CNC machine tool for rough machining of the front and back stations of precision deep groove parts, adopt radial and then axial layered milling, and leave a margin of 1.5 to 2.5mm for precision deep grooves.

[0023] The use of horizontal CNC machine tools is beneficial to the chip removal and temperature diffusion of the deep groove structure, and can effectively control the deformation of the precision deep groove.

[0024] (2) Place the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com