Powertrain Layout Method and Structure of Long Wheelbase Four-Wheel Drive Vehicle

An automotive powertrain and four-wheel drive technology, applied in power units, control devices, vehicle components, etc., can solve the problem of large dynamic load bending moment, large alternating variable load stress, and three Shell fatigue fracture and other problems, to achieve the effect of reducing the dynamic load bending moment and alternating variable load stress amplitude, reducing the alternating variable load stress and improving the stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

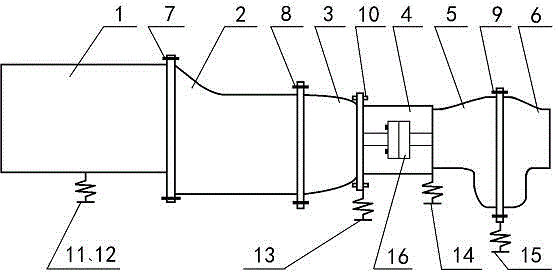

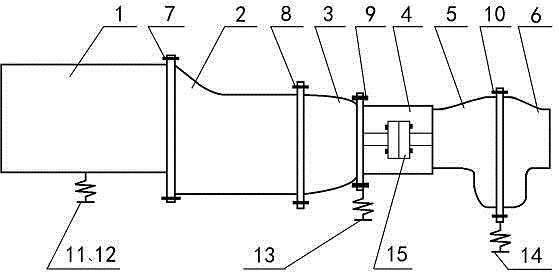

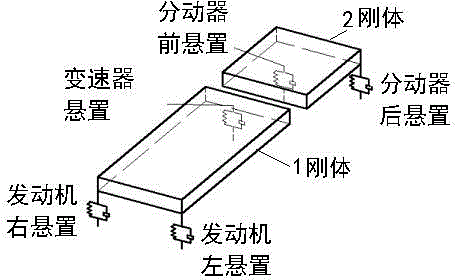

[0027] Such as figure 1 , 3 shown.

[0028] A powertrain arrangement method for a long-wheelbase four-wheel-drive vehicle. First, the engine casing with the engine mounted thereon is suspended on the vehicle frame through at least two points, and the two suspension points should be symmetrically distributed on both sides of the casing. At the same time, rigidly connect the engine casing to the front casing of the transmission, and rigidly connect the rear casing to the front casing of the transmission; secondly, suspend the transmission rigidly connected to the front and rear casings on the frame; thirdly, connect the rear casing of the transmission Flexible connection directly with the front case of the transfer case (a flexible connection can be formed by adding a rubber elastic bushing between the bolt and the mounting hole or other conventional connection methods, this connection method is actually a semi-rigid and semi-flexible connection ), and suspend the front case ...

Embodiment 2

[0030] Such as figure 1 , 3 shown.

[0031] A long-wheelbase four-wheel-drive vehicle powertrain layout structure, which includes an engine housing 1 with an engine installed, a transmission front housing 2 and a transmission rear housing 3, and a transfer case front housing with a transition plate 4 installed. Case 5 and transfer case rear case 6. The engine case 1 is suspended on the vehicle frame at least through two suspension points symmetrically arranged on both sides of the engine case. The engine case 1 and the front case 2 of the transmission One end is rigidly connected by a bolt 7, and the other end of the transmission front case 2 and one end of the transmission rear case 3 are rigidly connected by a bolt 8. After the rigid connection, the transmission front case 2 and the transmission rear case 3 are suspended on a suspension of the vehicle frame. point (finally located at one end close to the front case 5 of the transfer case, such as figure 1 ), at least tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com