A Speed Planning Method for Picking and Placeing Components by Nozzles of Chip Mounter

A speed planning, placement machine technology, applied in the direction of electric speed/acceleration control, etc., can solve problems such as motor out-of-step and stall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

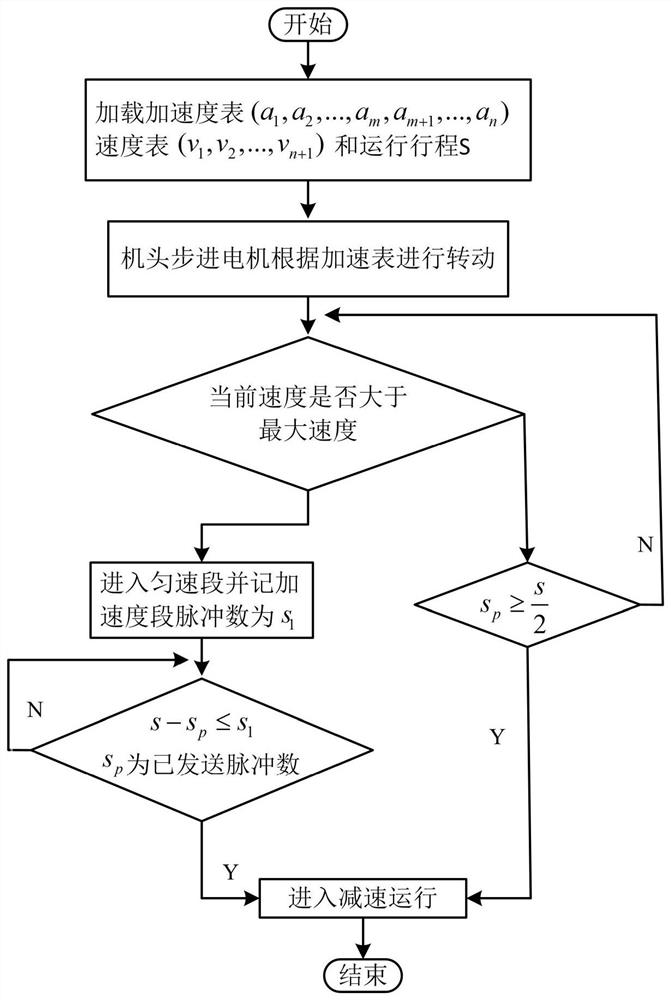

[0022] refer to figure 1 , figure 2 and image 3 , a speed planning method for pick-and-place components of a head nozzle of a placement machine, said method comprising the following steps:

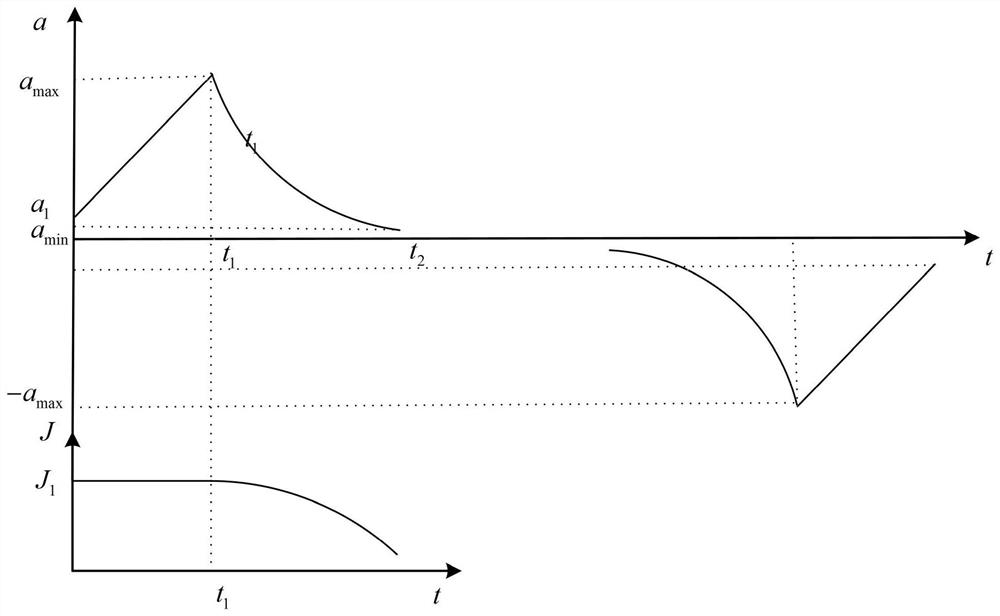

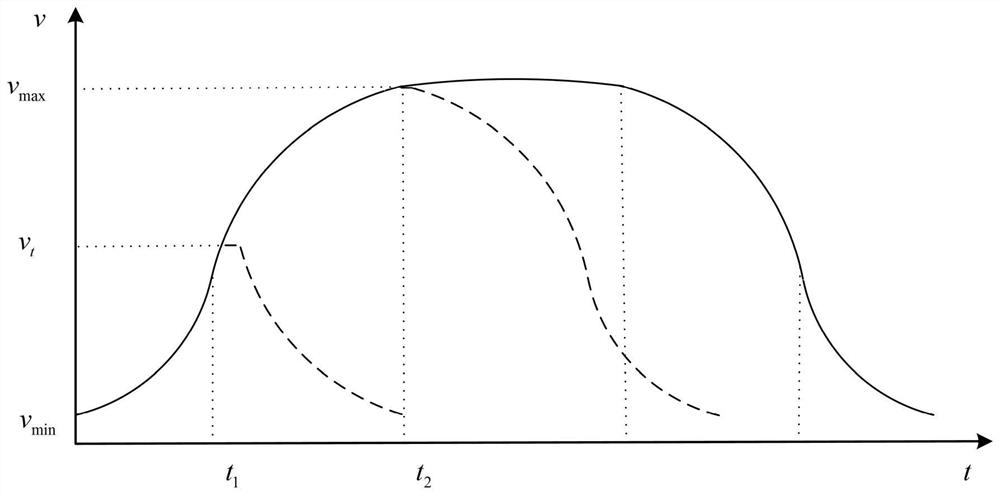

[0023] 1) In order to enable the head of the placement machine to start and stop more smoothly and accelerate to the maximum speed smoothly, an S-type acceleration mode is designed, in which, in the low-speed stage of the head running, the jerk J is maintained 1 constant, the acceleration movement with uniform acceleration increases, and the acceleration movement with reduced jerk is adopted during the high-speed acceleration stage of the nose, that is, the acceleration and deceleration sections of the acceleration curve are asymmetrical;

[0024] 2) According to the mechanical structure of the head nozzle of the placement machine, the suction force of the air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com