A machine vision technology detection method based on depth learning

A machine vision and technical detection technology, applied in the field of machine vision technology detection based on deep learning, can solve the problems of poor adaptability and stability, low classification accuracy, easy false detection and missed detection, etc., to achieve adaptability and stability. Good, avoid missed detection and false detection, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

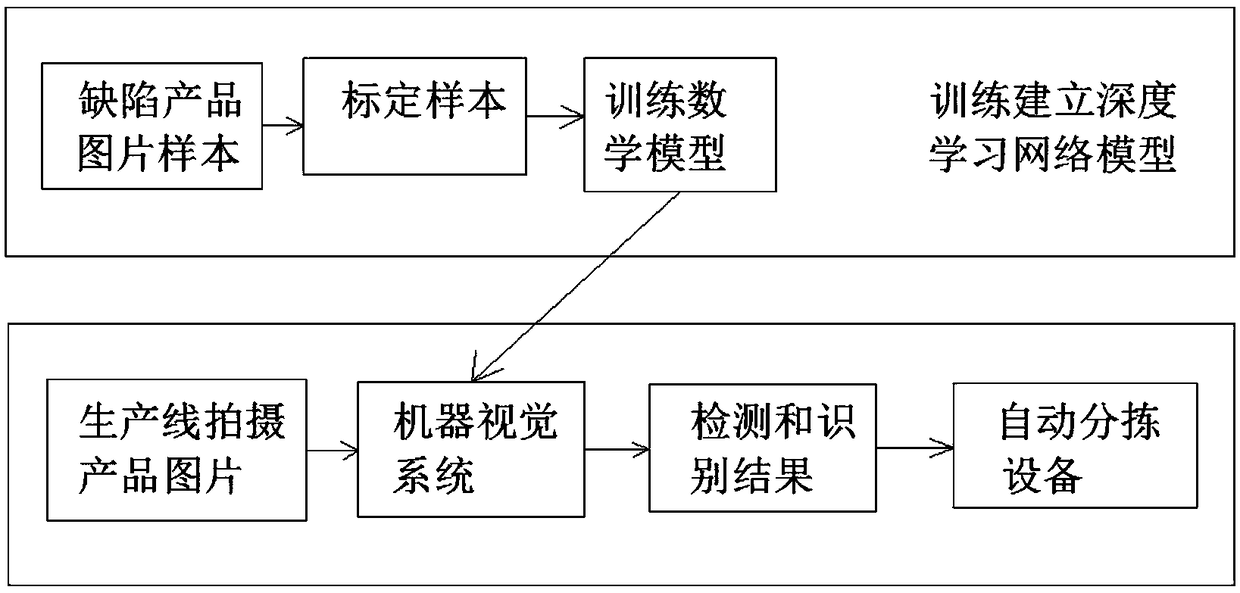

[0028] see as figure 1 and figure 2 As shown, this specific implementation is to apply the machine vision technology detection method based on deep learning to the identification of capacitance defects, and the technical solution it adopts is:

[0029] 1. Construct a real capacitance defect dataset Dataset1, try to use the same industrial camera and light source as the final detection and sorting automation system to take pictures of capacitance defects, select about 6000 capacitance defect images, and mark each image with its capacitance defect location and attributes (The attribute value of capacitance defect includes capacitance defect type and severity value);

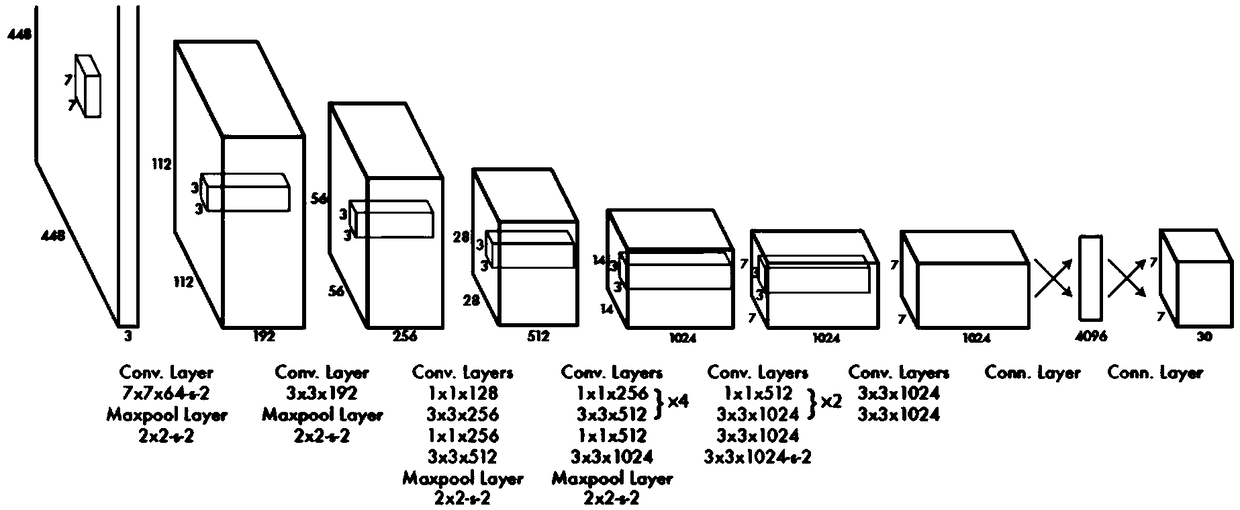

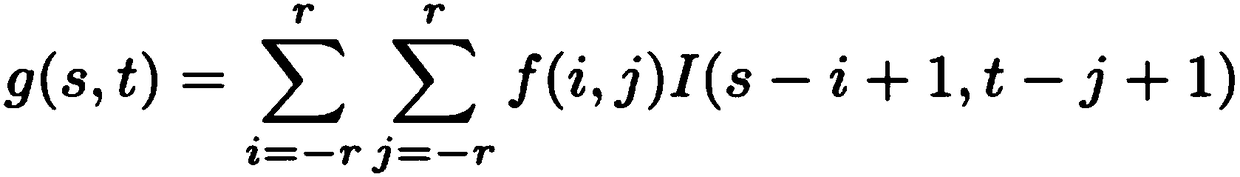

[0030] 2. Construct a deep convolutional neural network model. The network model structure consists of several convolutional layers, pooling layers, fully connected layers and an output layer. The output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com