A method and apparatus for disconnecting a metal wire for an image sensor chip

An image sensor, metal wire technology, applied in radiation control devices, electric solid state devices, semiconductor devices, etc., can solve the problems of low packaging efficiency, increased camera module cost, long process, etc., to facilitate positioning and assembly, and increase packaging. Flexibility, the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

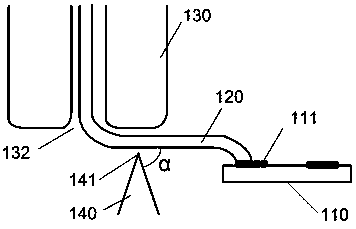

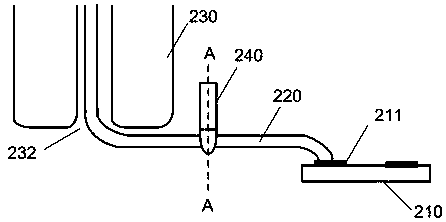

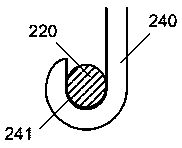

[0027] In order to solve the above-mentioned problems in the prior art, the present invention provides a metal wire disconnection method and device for an image sensor chip, wherein the first welding spot of the metal wire is electrically connected to the image sensor chip by heating and ultrasonic welding. Pad, the other end of the metal wire is cut off and suspended from the image sensor chip, forming a packaging structure in which the first solder point of the metal wire is connected to the pad of the image sensor chip, and the other end is suspended outside the image sensor chip, increasing the image The packaging flexibility of the sensor chip facilitates the positioning and assembly of the chip and the lens, improves the performance of the camera module, shortens the process flow, improves the product yield, and reduces the cost of the camera module.

[0028] In the following detailed description of the preferred embodiment, reference is made to the accompanying drawings ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com