A kind of dynamic furnace temperature control method of hot rolling heating furnace

A control method and heating furnace technology, applied in the field of steel rolling, can solve problems such as high temperature of silicon steel, affecting product quality, failing to meet process requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

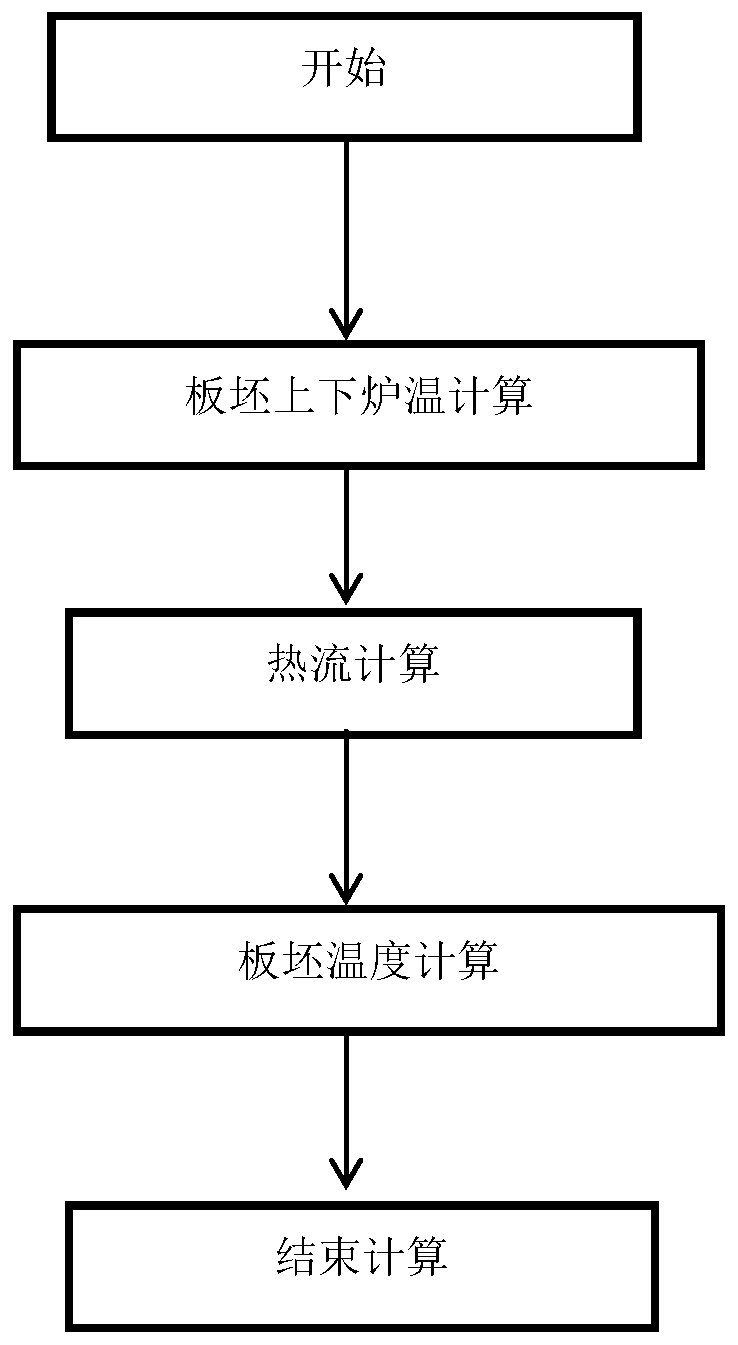

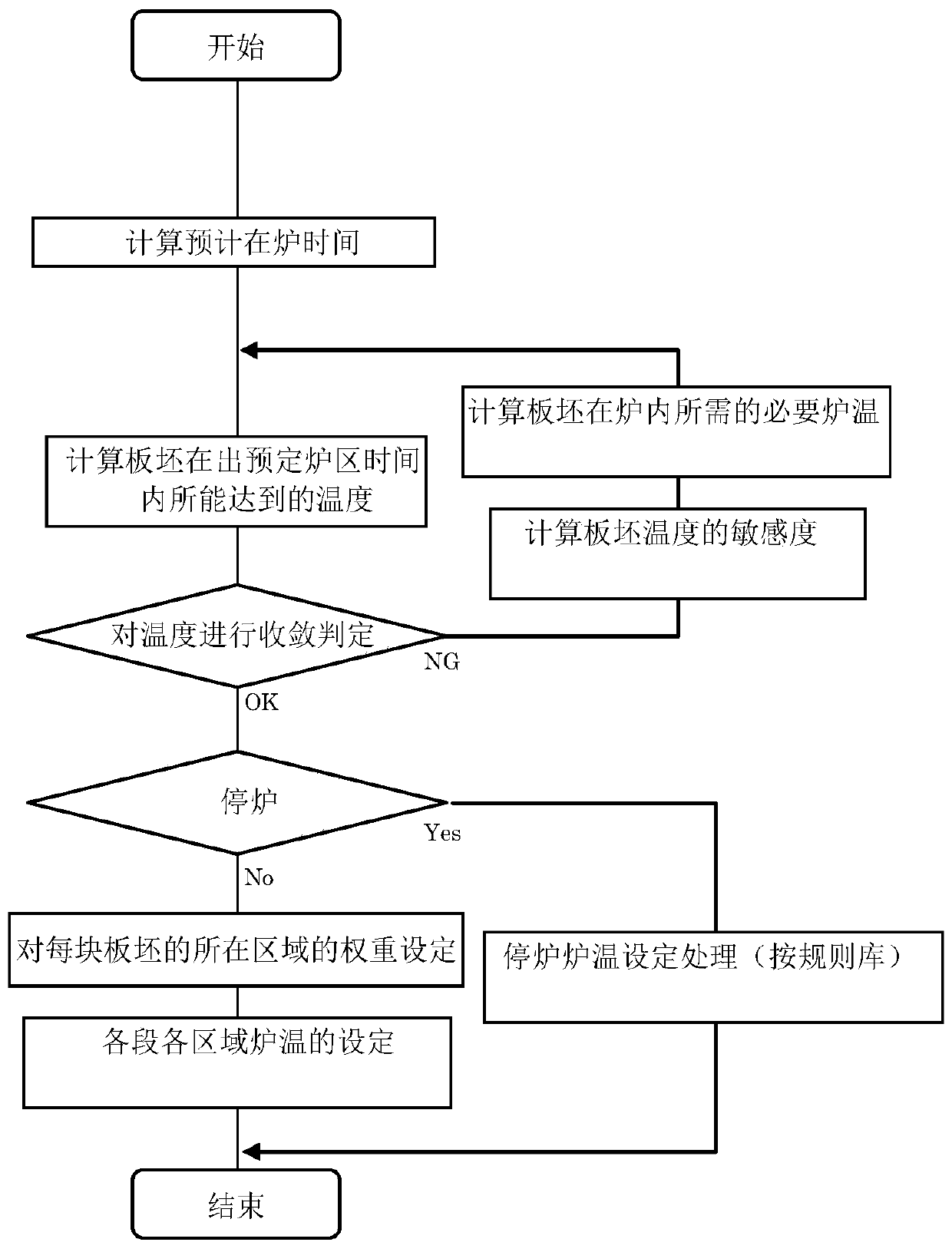

Method used

Image

Examples

Embodiment 1

[0139] Seeing table 1 is the heating billet original plan data of the present embodiment:

[0140] Table 1: Original Plan Data Implementation Example Table Cold Scale Values

[0141] steel type Slab Thickness Slab width Slab length heating target temperature 1 50A-MZ13 230mm 1280mm 10610mm 1140℃ 2 50A-MZ13 230mm 1280mm 10600mm 1140℃

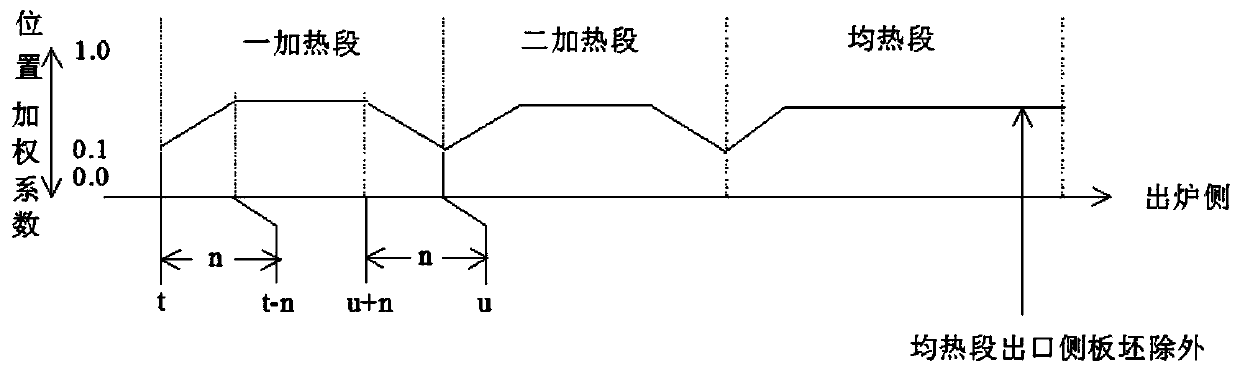

[0142] In this example, different control methods are used to heat two slabs, the same steel type is 50A-MZ13, and the specifications are almost the same. Among them, No. 1 slab adopts the furnace temperature control method of the original system. No. 2 slab adopts the furnace temperature control method of this method, and the 50A-MZ13 steel grade is added in the special steel control database table, and the weighting coefficient rule belongs to the furnace temperature setting rule of the specific steel grade. Since the 50A-MZ13 steel belongs to silicon steel, it is sensitive to the process temp...

Embodiment 2

[0146] Seeing table 2 is the heating billet original plan data of the present embodiment:

[0147] Table 2: Original Plan Data Implementation Example Table Cold Scale Values

[0148] steel type Slab Thickness Slab width Slab length heating target temperature 1 SPCC 230mm 1080mm 9690mm 1220℃ 2 SPCC 230mm 1080mm 9460mm 1220℃

[0149] In this example, different control methods are used to heat two slabs, the same steel type is SPCC, and the specifications are almost the same. Among them, No. 1 slab adopts the furnace temperature control method of the original system. No. 2 slab adopts the furnace temperature control method of this method. Since the SPCC steel grade is not in the specific steel grade database table, the new method program judgment adopts the average necessary furnace temperature setting rule. Because SPCC steel grades are also sensitive to process temperature, the weighted calculation priority is high. In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com