A carbonaceous material wide temperature range anti-oxidation repair coating and its repair and preparation method

A carbonaceous material and wide temperature range technology, which is applied in the field of carbonaceous material wide temperature range anti-oxidation repair coating and repair, can solve the problems of poor high temperature stability of the repair coating and small applicable temperature range, and achieve anti-oxidation protection , Stable high temperature oxidation resistance, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

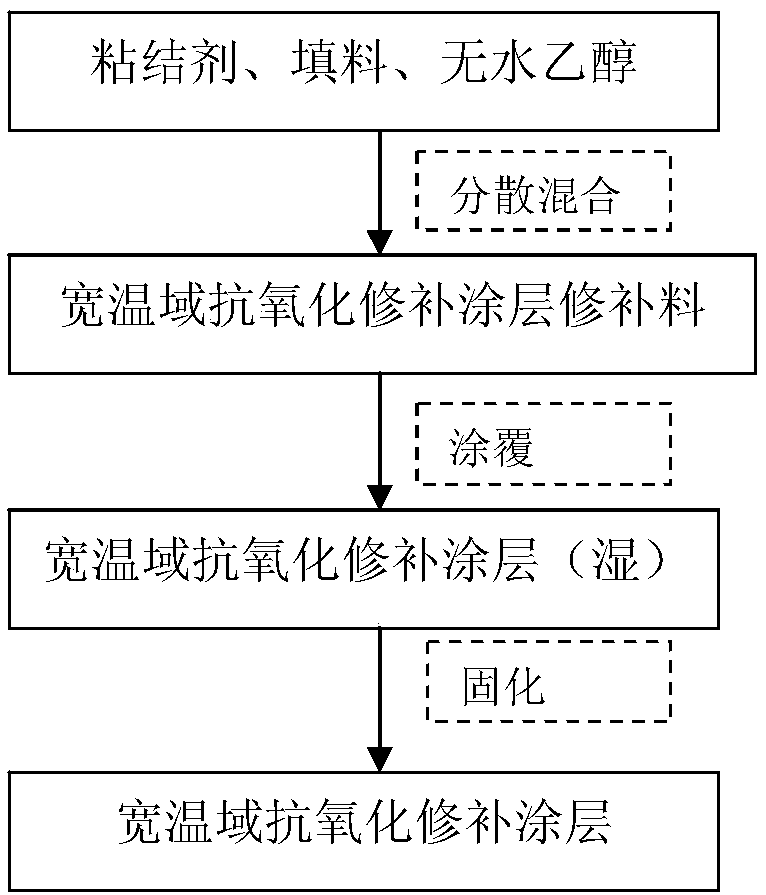

Method used

Image

Examples

Embodiment 1

[0059] For local coating defects such as blind holes, deep pits, and grooves where the depth of the defect is greater than 1mm, a putty-type repairing material with high solid content and high viscosity is prepared. The following material ratio is selected: phenolic resin 20%, silicon 50%, boron carbide 5%, silicon carbide 20%, absolute ethanol 5%. After the above materials are fully dispersed and mixed, a repair compound is formed. Apply the repair material to the area to be repaired by scraping to fill the surface of the carbonaceous material.

[0060] Then, further brush the surface of the filled area with a less viscous slurry. The following material ratio is selected: 30% of silica sol, 25% of silicon, 20% of boron carbide, 5% of diboron trioxide, and 20% of absolute ethanol. After the above materials are fully dispersed and mixed, a repair compound is formed. Apply the repair compound to the area to be repaired by brushing or spraying so that the repair coating is flu...

Embodiment 2

[0066] For local coating defects such as blind holes, deep pits, and grooves where the depth of the defect is greater than 1mm, a putty-type repairing material with high solid content and high viscosity is prepared. The following material ratio is selected: 35% of silicone resin, 35% of silicon, 10% of boron carbide, 10% of silicon carbide, and 10% of absolute ethanol. After the above materials are fully dispersed and mixed, a repair compound is formed. Apply the repair material to the area to be repaired by scraping, and fill up the blind holes, deep pits and grooves.

[0067] Then, further brush the surface of the filled area with a less viscous slurry. The following material ratio is selected: 20% of silicone resin, 30% of silicon, 5% of boron carbide, 5% of silicon carbide, 5% of diboron trioxide, and 35% of absolute ethanol. After the above materials are fully dispersed and mixed, a repair compound is formed. Apply the repair compound to the area to be repaired by brus...

Embodiment 3

[0073] For local coating defects such as blind holes, deep pits, and grooves where the depth of the defect is greater than 1mm, a putty-type repairing material with high solid content and high viscosity is prepared. The following material ratio is selected: 25% of silicone resin, 40% of silicon, 5% of boron carbide, 15% of silicon carbide, and 15% of absolute ethanol. After the above materials are fully dispersed and mixed, a repair compound is formed. Use the method of scraping and brushing to apply the repair material to the area to be repaired, and fill the blind holes, deep pits and grooves.

[0074] After the repair coating is applied, it should be surface-dry at room temperature for 1 hour, and then use a quartz lamp to heat and cure the repaired area. The following curing process system can be used:

[0075] Starting from room temperature, the temperature is raised freely to 100±10°C (2±0.25 hours of heat preservation), and then the temperature is raised freely twice i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com