Method for producing beryllium bronze strip by using continuous heat-treating furnace

A heat treatment furnace, beryllium bronze technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as unstable temperature control accuracy, difficulty in producing thick strips, and insufficient air flotation capacity, so as to reduce production costs and increase production capacity , the effect of uniformity guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The beryllium bronze strip used for annealing is a QBe2 / C17200 strip with a thickness of 0.5mm, a width of 450mm and a length of 1000m, and its original mechanical properties are shown in Table 1-1.

[0021] 1. Pretreatment: The strip is degreased, degreased, washed with high-pressure hot water, and blown with hot air in order to ensure the surface of the strip is clean, and then enters the furnace body from the top of the furnace body sequentially through the inlet looper and the inlet pinch roller. The entire belt speed was set at 10 m / min.

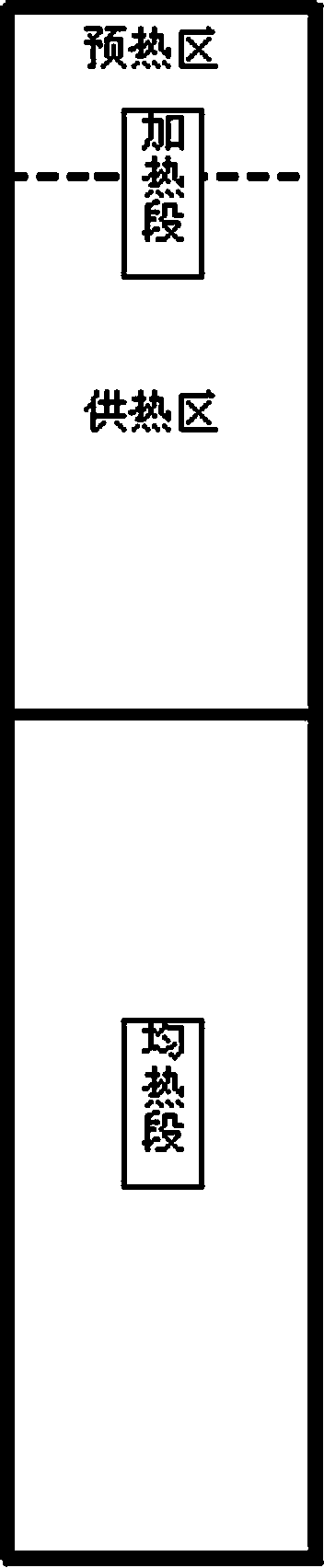

[0022] 2. Preheating: After the strip enters the furnace, it first enters the preheating zone of the heating section. The temperature of the preheating zone is set at 750-800°C, and the strip enters the heating zone of the heating section after preheating. The combustion control method mainly adopts flow regulation. The flow of natural gas and combustion-supporting air are calculated by a microcomputer and then accurately propo...

Embodiment 2

[0028] 1. Pretreatment: The beryllium bronze strip for annealing is a C17510 strip with a thickness of 0.3mm, a width of 430mm and a length of 1500m, and its original mechanical properties are shown in Table 2-1. The strip is degreased, degreased, washed with hot water, and blown with hot air in order to ensure the surface of the strip is clean, and then enters the furnace body from the top of the furnace body sequentially through the inlet looper and the inlet pinch roller. The entire belt speed was set at 25 m / min.

[0029] 2. Preheating: After the strip enters the furnace, it first enters the preheating zone of the heating section. The temperature in the preheating zone is set at 800-880°C, and the strip enters the heating zone of the heating section after preheating. The combustion control method mainly adopts flow regulation. The flow of natural gas and combustion-supporting air is calculated by a microcomputer and then accurately proportioned, and then input into the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com