Tool fixture applied to bucket welding robot workstation

A welding robot, tooling and fixture technology, applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problem of not being able to adapt to various sizes of buckets, and achieve the effect of simple structure, improved practicability, and avoidance of cumbersome operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

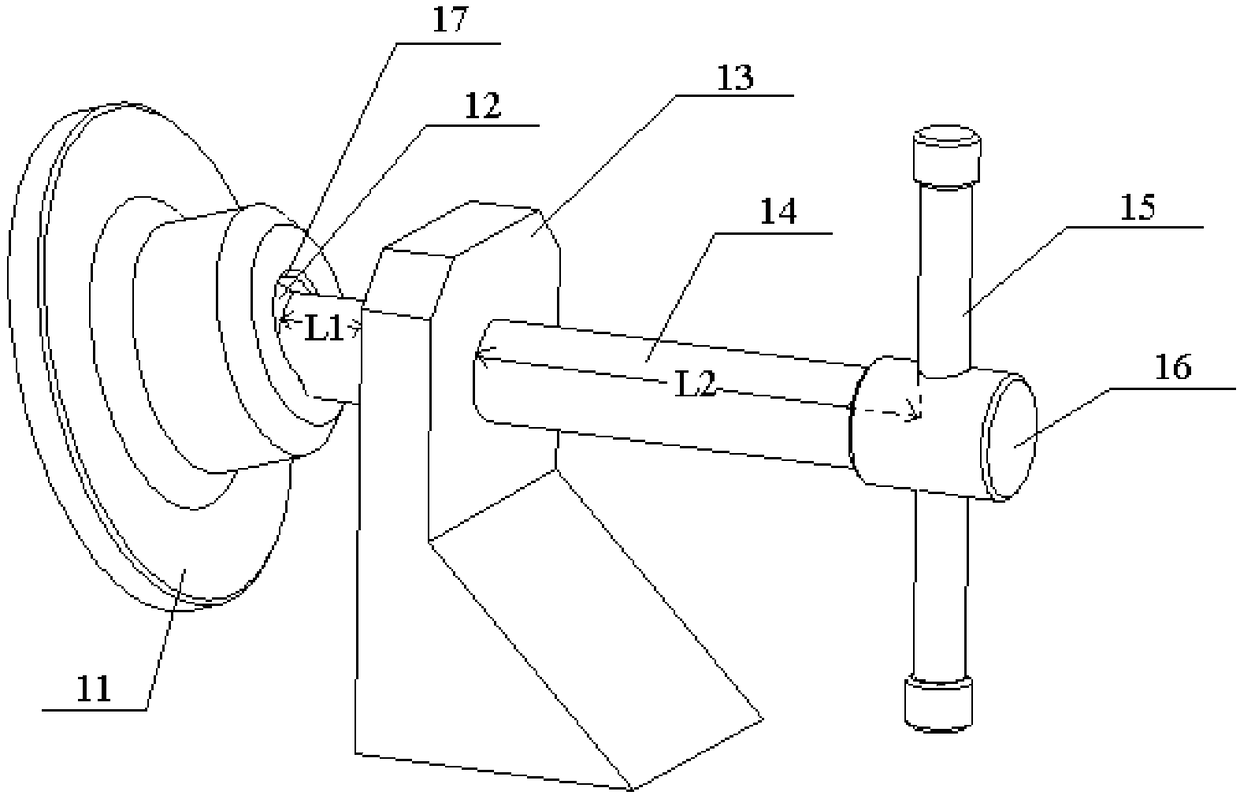

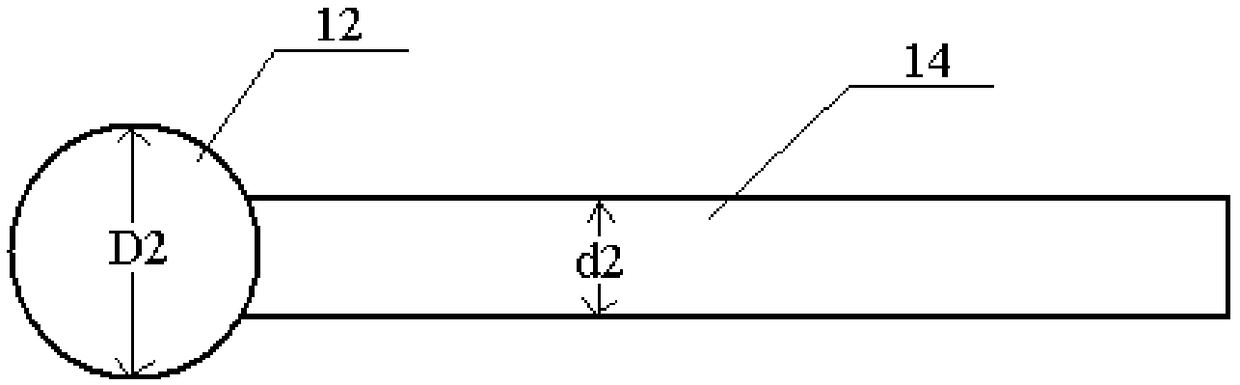

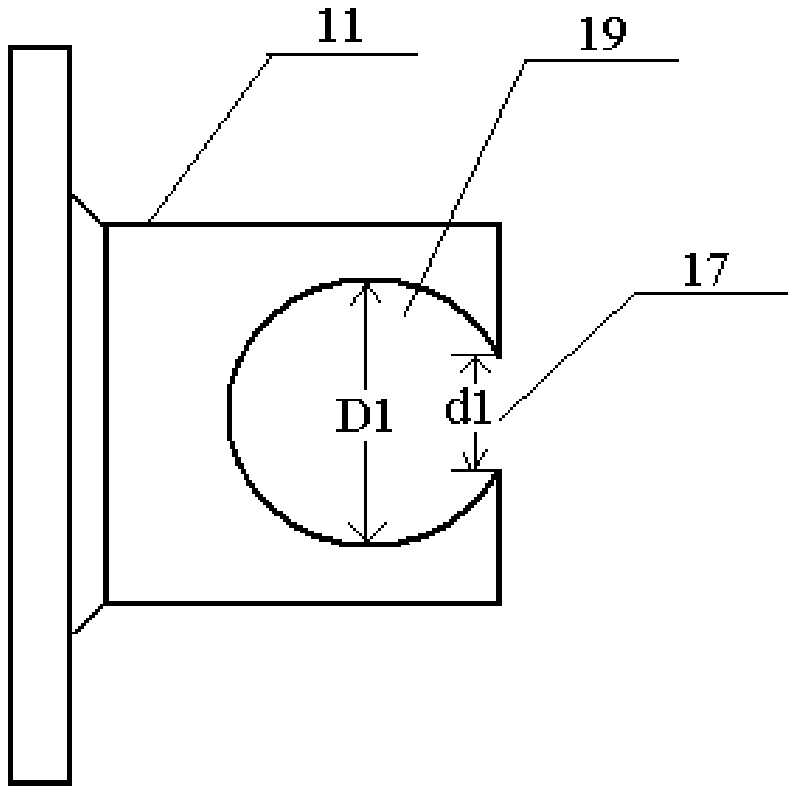

[0039] figure 1 It is a schematic diagram of the pressing mechanism applied to the bucket welding robot workstation according to the embodiment of the present invention; figure 2 yes figure 1 Schematic diagram of the self-locking screw rod; image 3 is a cross-sectional view of the floating pressure head in the figure.

[0040] Such as Figure 1-Figure 3 The shown pressing mechanism applied to the bucket welding robot workstation includes a floating pressure head 11, a self-locking screw rod 14, a support 13, and a trigger lever 15; the rear end of the floating pressure head 11 is provided with a self-locking wire The cavity 19 connected by the rod, the front end of the self-locking screw rod 14 is connected with a spherical part 12, the spherical part 12 is arranged in the cavity 19, the diameter D1 of the cavity 19 is greater than the diameter D2 of the spherical part 12, and the opening of the cavity 19 The diameter d1 is smaller than the diameter D2 of the spherical m...

Embodiment 2

[0044] Figure 4 It is a schematic diagram of another embodiment of the present invention applied to the pressing mechanism of the bucket welding robot workstation; Figure 5 yes Figure 4 Schematic diagram of the self-locking screw rod; Figure 6 yes Figure 4 Cross-sectional view of the floating indenter.

[0045] Such as Figure 4-Figure 6 The shown pressing mechanism applied to the bucket welding robot workstation includes a floating pressure head 21, a self-locking screw rod 24, a support 23, and a trigger lever 25; the rear end of the floating pressure head 21 is provided with a self-locking wire The cavity 29 that the rod 24 communicates, the front end of the self-locking screw rod 24 is connected with a spherical part 22, the spherical part 22 is arranged in the cavity 29, the diameter D1 of the cavity 29 is greater than the diameter D2 of the spherical part 22, and the diameter D2 of the cavity 29 The opening diameter d1 is smaller than the diameter D2 of the sph...

Embodiment 3

[0050] Figure 7 It is a schematic diagram of the tooling fixture applied to the bucket welding robot workstation in this embodiment. Such as Figure 7 As shown, the tooling fixture applied to the bucket welding robot workstation includes a positioning assembly and a support assembly supporting the positioning assembly; the positioning assembly includes two first positioning assemblies respectively arranged outside the two slopes of the bucket Assembly 1 and two second positioning assemblies 2 respectively arranged outside the two facades of the bucket; the first positioning assembly 1 and the second positioning assembly 2 are provided with a universal pressing mechanism 3; The support assembly includes a "mouth"-shaped support frame 4 and a support plate arranged on the support frame 4 and matched with the bucket opening surface; the first positioning assembly 1 is connected to the support plate; the The second positioning assembly 2 is connected with the support frame 4 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com