Intelligent acid discharge device

A technology of acid discharge and acid storage, applied in the direction of inorganic chemistry, sulfur compounds, chemical instruments and methods, etc., can solve the problems of low intelligence, equipment corrosion, hidden dangers of production system safety, etc., to avoid splashing and hurt people, and reduce corrosion , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

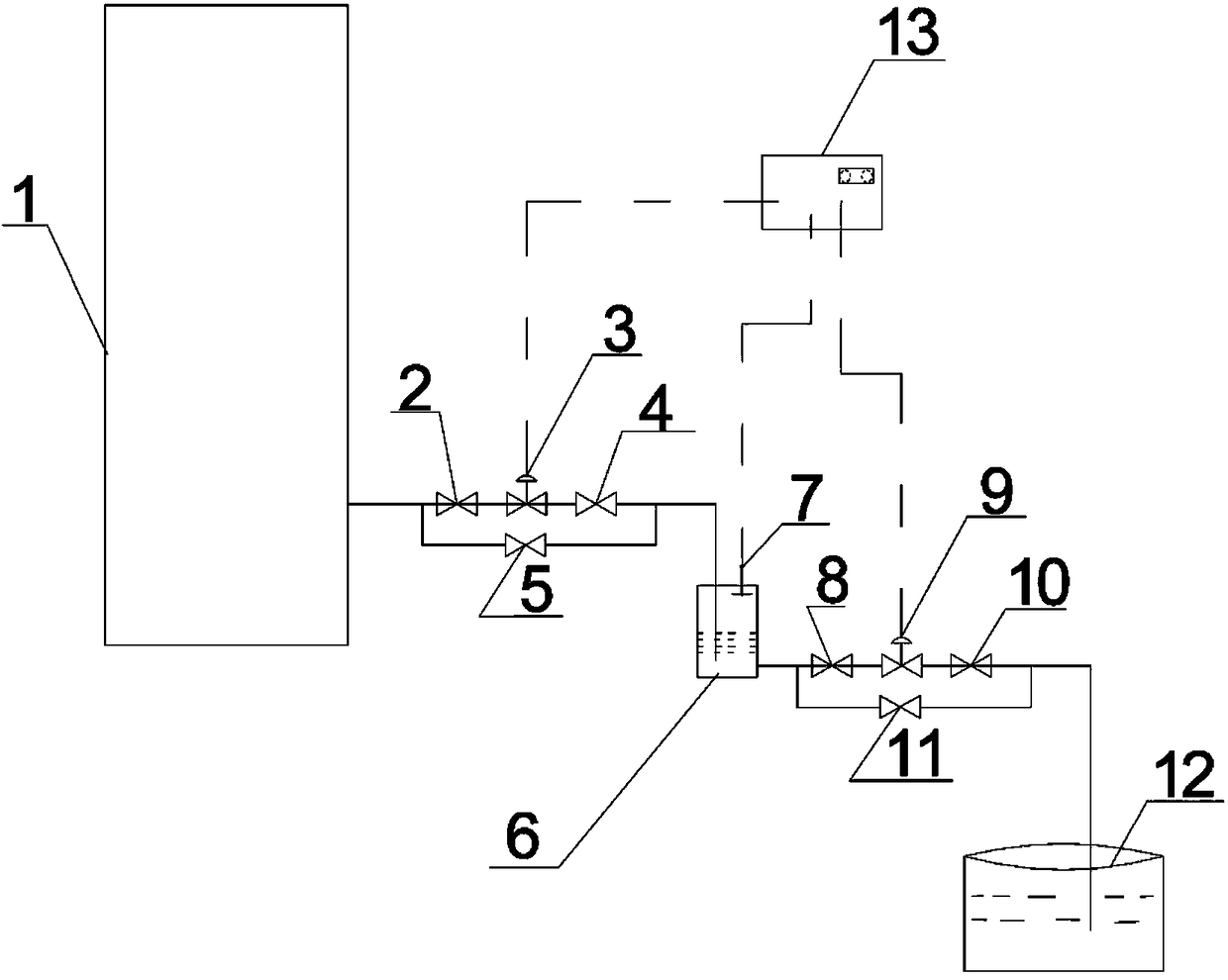

[0014] Such as figure 1 An intelligent acid discharge device is shown, which includes an absorption tower 1, the absorption tower 1 is connected to a buffer 6, and a first front cut-off valve 2, a regulating valve 3, a first The rear cut-off valve 4, the branch formed by the first front cut-off valve 2, the regulating valve 3 and the first rear cut-off valve 4 in series are connected in parallel with the first bypass valve 5, and the buffer 6 is connected with the acid storage tank 12. 6 and the acid storage tank 12 are connected in series with the second front cut-off valve 8, the acid discharge regulating valve 9 and the second rear cut-off valve 10, the second front cut-off valve 8, the acid discharge regulating valve 9 and the second rear cut-off valve 10 The branch formed in series is connected in parallel with the second bypass valve 11, the top of the buffer 6 is provided with a liquid level gauge 7, the root regulating valve 3, the liquid level gauge 7, and the acid di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com