Waste heat recycling system for semi coke production, and use method thereof

A semi-coke and waste heat technology, applied in the field of waste heat recycling system for semi-coke production, can solve problems such as difficult to find and replace, low heat absorption efficiency, damage to heat exchange equipment, etc., to achieve convenient maintenance and replacement, increase the heating area, The effect of increasing production efficiency

Active Publication Date: 2019-01-22

内蒙古蓝色火宴科技环保股份公司

View PDF7 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the high-temperature semi-coke produced by the traditional vertical charcoal furnace after processing the semi-coke, before cooling the semi-coke, the waste heat of the semi-coke will be absorbed and reused. The heat absorption efficiency of the equipment is low, the effect is poor, and in the process of using the semi-coke waste heat, the semi-coke is easy to cause damage to the heat exchange equipment after falling, but the heat exchange equipment is often installed in the insulation wall, which is difficult to find and replace, which affects the waste heat Utilization and the whereabouts of semi-coke, causing blockage in the tank

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

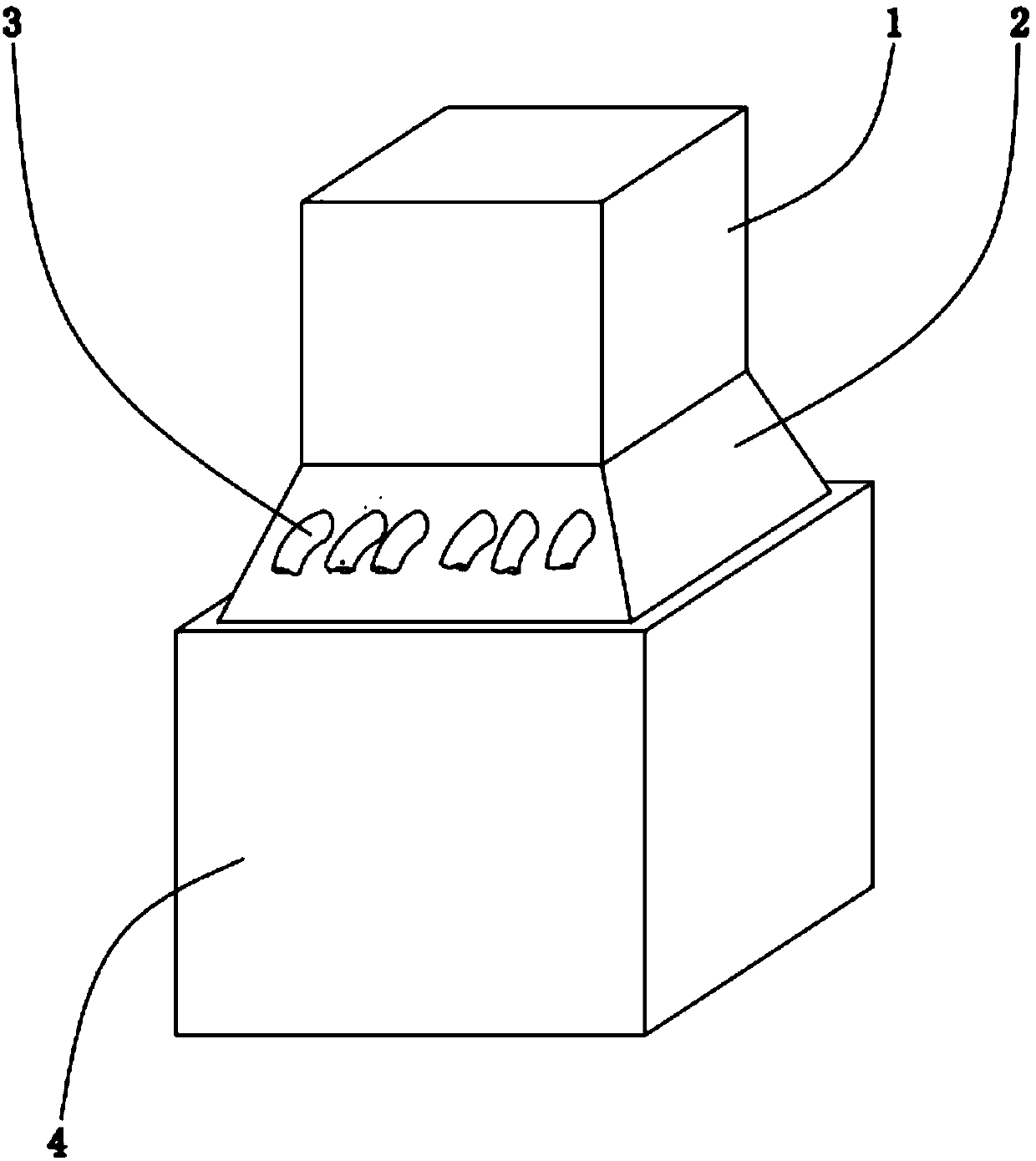

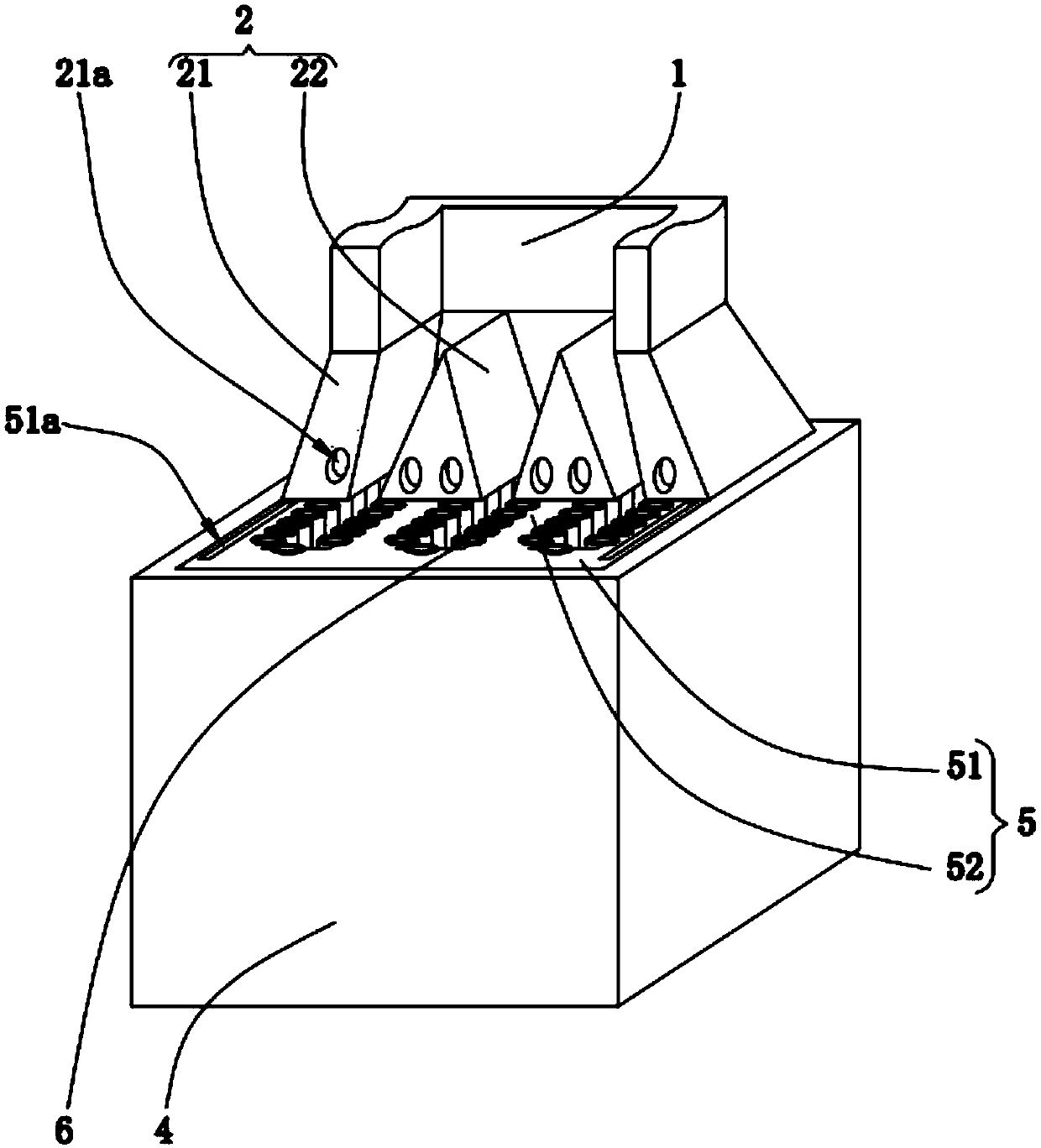

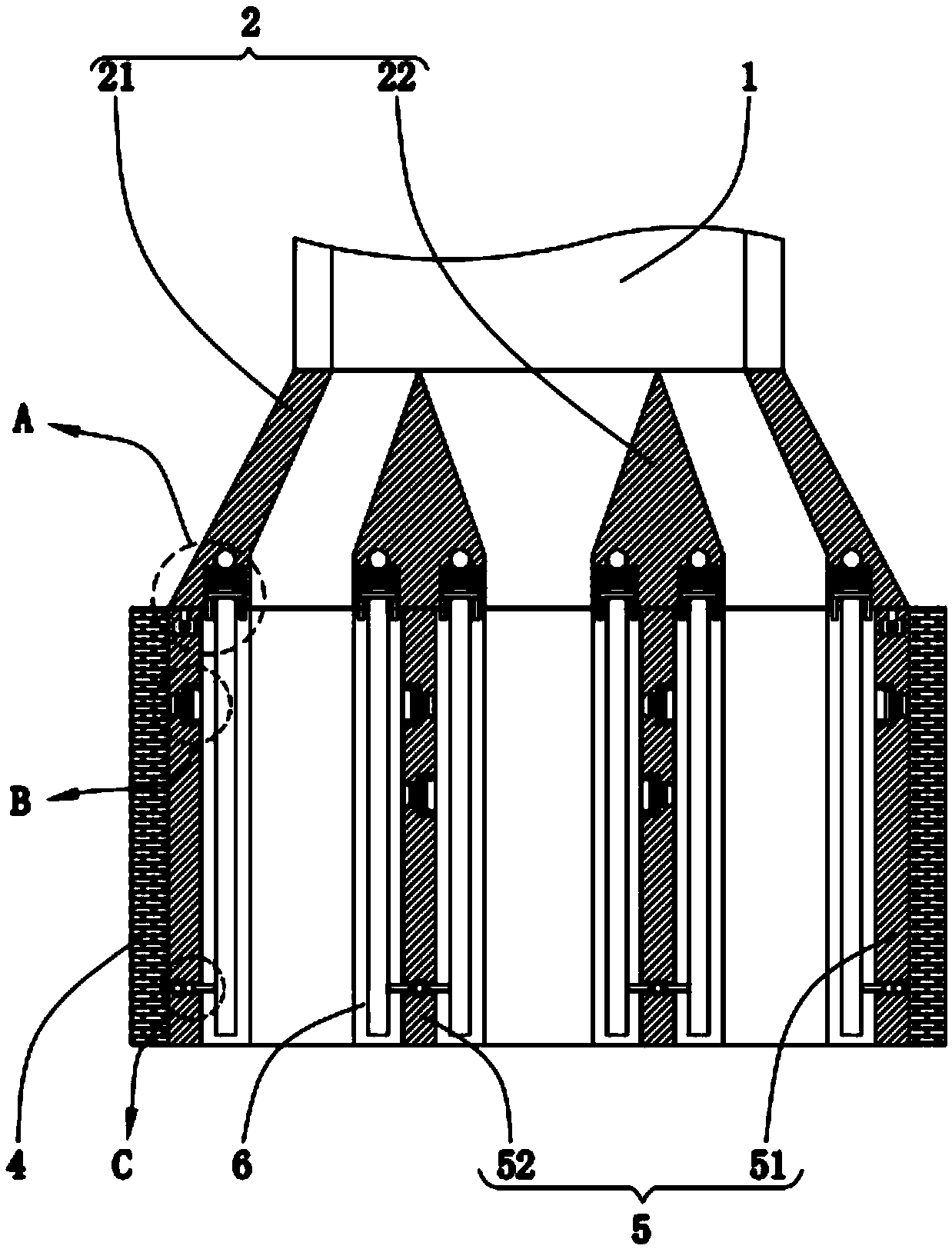

The invention provides a waste heat recycling system for semi coke production, and a use method thereof. The waste heat recycling system comprises: a combustion furnace; a connection mechanism; a steam through pipe; a fixing mechanism used for fixing a heat exchange column and connected to a connection shell; the heat exchange column; a heat insulating wall; a driving mechanism used for driving the sliding of the connection shell and connected between the connection shell and a fixed shell; a water inlet mechanism used for continuously feeding water into the heat exchange column so as to continuously generate water vapor, arranged in the fixed shell, and connected to the heat exchange column; an installing mechanism used for fixing the heat exchange column in the installation groove on thefixed shell and connected between the heat exchange column and the fixed shell; and a sealing mechanism. The waste heat recycling system of the present invention has characteristics of high waste heat utilization efficiency, good effect, and convenient maintenance and replacement of the heat exchange column.

Description

technical field The invention relates to the technical field of semi-coke production and processing, in particular to a waste heat recycling system for semi-coke production and a use method thereof. Background technique Semi-coke is fired from the high-quality Jurassic clean coal abundant in Shenfu Coalfield. As a new type of carbon material, it has high fixed carbon, high specific resistance, high chemical activity, low ash content, low aluminum, The characteristics of low sulfur and low phosphorus are widely used. During the production and processing of semi-coke, it is processed through a vertical charcoal furnace. After the vertical furnace is processed, high-temperature semi-coke is produced, and semi-coke needs to be cooled to form a finished product. However, the high-temperature semi-coke produced by the traditional vertical charcoal furnace after processing the semi-coke will absorb and reuse the waste heat of the semi-coke before cooling the semi-coke. The heat a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B32/05

CPCC01B32/05Y02P20/10Y02P20/129

Inventor 程建平

Owner 内蒙古蓝色火宴科技环保股份公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com