Brake pad and brake friction pair using same

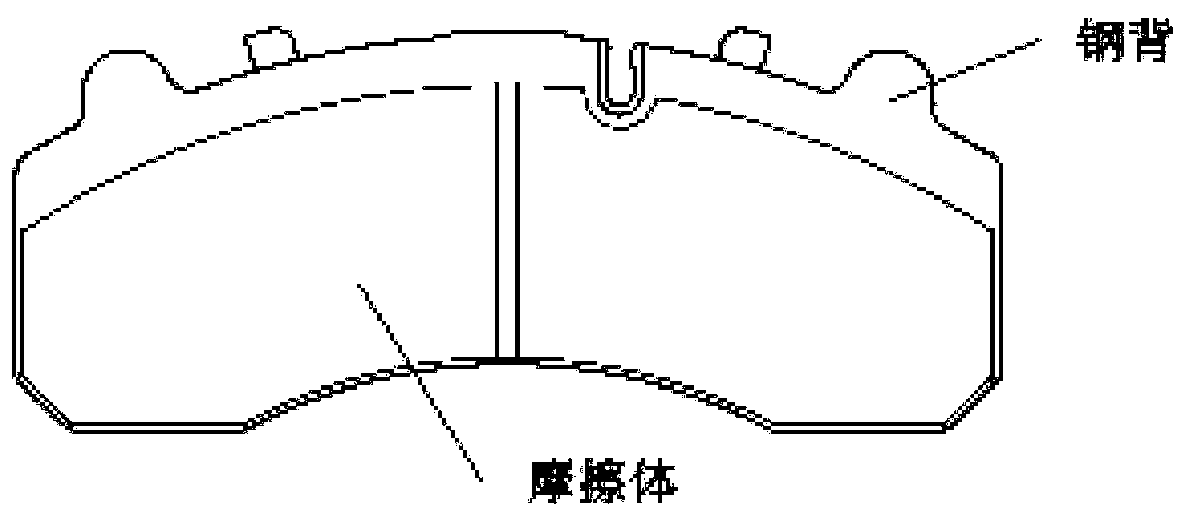

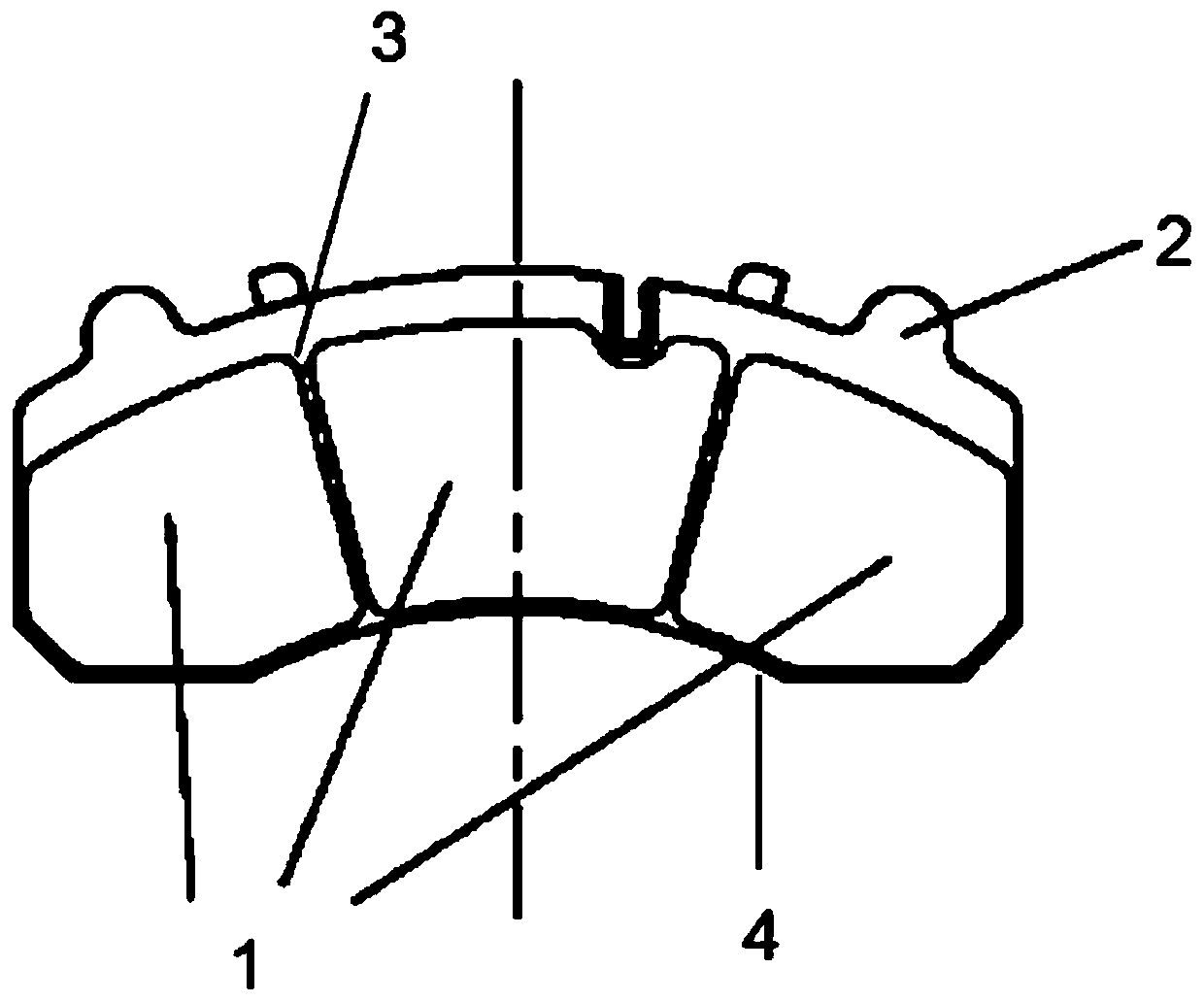

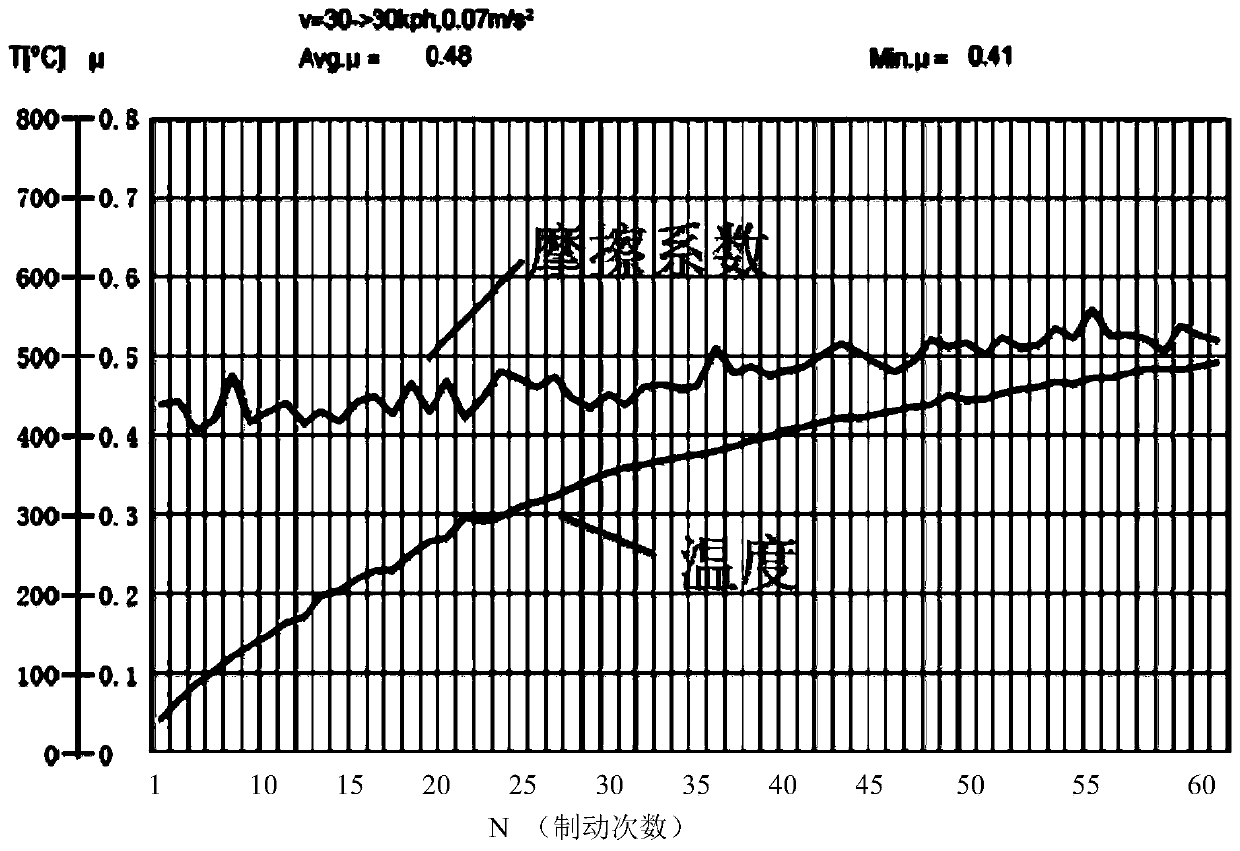

A technology of brake pads and friction blocks, which is applied in the field of automobile/high-speed rail accessories, can solve the problems of difficult to meet the rear wheel braking requirements of heavy-duty commercial vehicles, low absolute braking torque, unstable friction performance, etc., to prevent the block from falling off. , the braking performance is stable, the effect of improving the impact resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The raw material composition of the friction block: see Table 1.

[0045] Preparation:

[0046] (1) Clean, sandblast, and pre-coat the steel back connected to the friction block of the brake pad, and wait for use after the treatment is completed;

[0047] (2) Put the raw materials used into the mixer and mix them for 20 minutes;

[0048] (3) Weigh the mixed powder according to the design weight, add it into the cavity, and press it, the pressing pressure is 350MPa, and the holding time is 20s;

[0049] (4) Carry out three-stage sintering of the pressed compact and the pretreated steel back under a hydrogen protective atmosphere, the first stage of normal pressure sintering, the sintering temperature is 1000 ° C, and the holding time is 80 minutes; the second stage is pressurized For sintering, the sintering temperature is constant, the pressure is 2.5 MPa, and the pressure is kept for 30 minutes; the third stage of normal pressure sintering, the sintering temperature ...

Embodiment 2

[0054] The raw material composition of the friction block: see Table 1.

[0055] Preparation:

[0056] (1) Clean, sandblast, and pre-coat the steel back connected to the friction block of the brake pad, and wait for use after the treatment is completed;

[0057] (2) Put the raw materials used into the mixer and mix for 30 minutes;

[0058] (3) Weigh the mixed powder according to the design weight, add it into the cavity, and press it, the pressing pressure is 450MPa, and the holding time is 10s;

[0059] (4) Carry out three-stage sintering of the pressed compact and the pretreated steel back under a hydrogen protective atmosphere, the first stage of normal pressure sintering, the sintering temperature is 980 ° C, and the holding time is 100 minutes; the second stage is pressurized For sintering, the sintering temperature is constant, the pressure is 4.5 MPa, and the pressure is kept for 20 minutes; the third stage of normal pressure sintering, the sintering temperature is 1100...

Embodiment 3

[0064] The raw material composition of the friction block: see Table 1.

[0065] Preparation:

[0066] (1) Clean, sandblast, and pre-coat the steel back connected to the friction block of the brake pad, and wait for use after the treatment is completed;

[0067] (2) Put the raw materials used into the mixer and mix for 40 minutes;

[0068] (3) Weigh the mixed powder according to the design weight, add it into the cavity, and press it, the pressing pressure is 500MPa, and the holding time is 10s;

[0069] (4) Carry out three-stage sintering of the pressed compact and the pretreated steel back under a hydrogen protective atmosphere, the first stage of normal pressure sintering, the sintering temperature is 1050 ° C, and the holding time is 120 minutes; the second stage is pressurized For sintering, the sintering temperature is constant, the pressure is 0.5MPa, and the pressure is maintained for 20 minutes; the third stage of normal pressure sintering, the sintering temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com