Comb driver with self-cleaning function

A driver and comb-tooth technology, applied in the field of micro-electromechanical, can solve the problems of comb-tooth driver and device failure, etc., and achieve the effects of low cost, easy processing, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

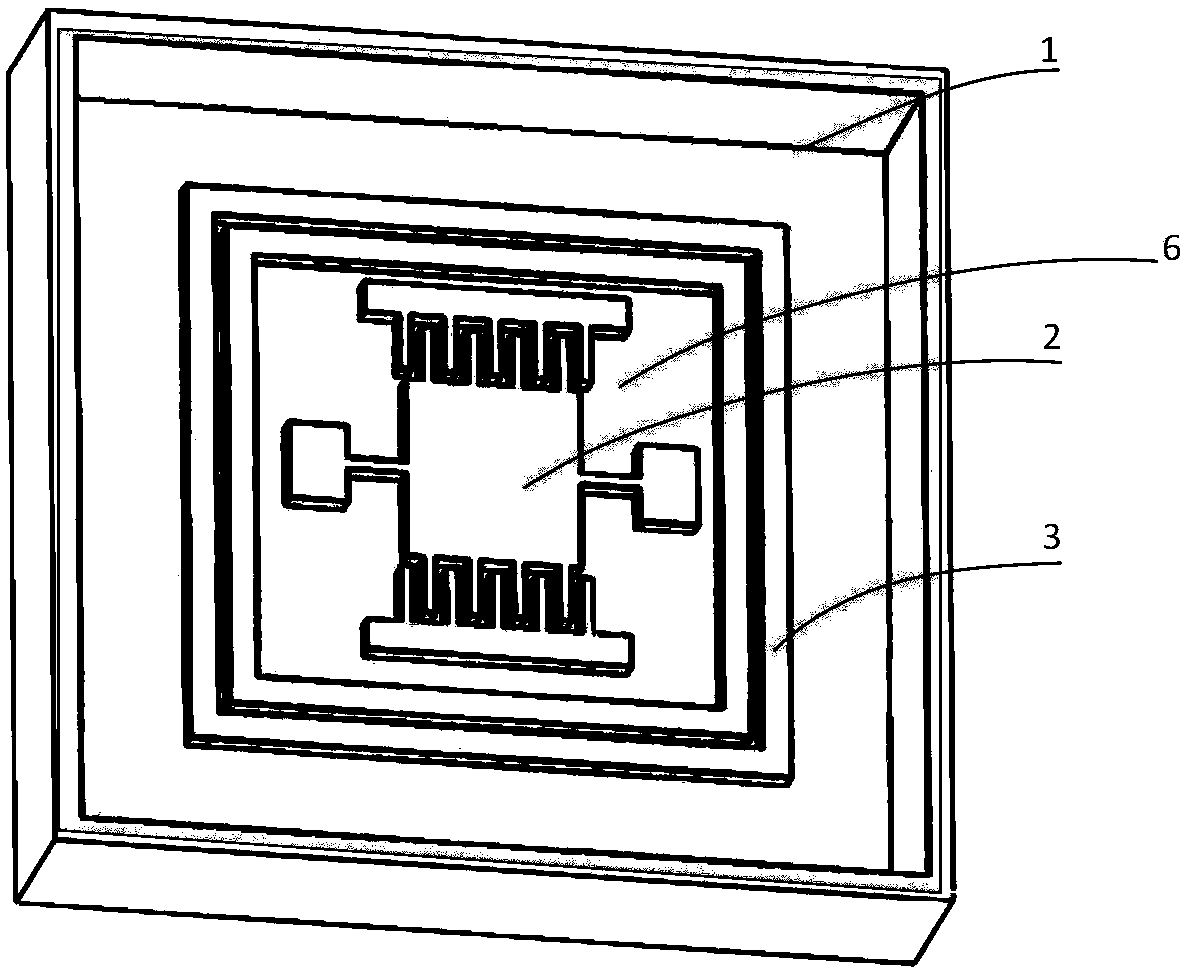

[0030] from figure 1 It can be seen that the self-cleaning comb driver in this embodiment mainly includes a closed casing 1 , a drive comb 2 , a silicon substrate 6 and an adsorption electrode 3 . The driving comb 2 and the adsorption electrode 3 are arranged on the silicon substrate 6 and located inside the closed casing 1. The closed casing 1 provides a closed working space for the comb driver to isolate the interference from the external space; the driving comb 2 drives the MEMS device to work, and the adsorption Electrode 3 is used to adsorb particles in the closed enclosure.

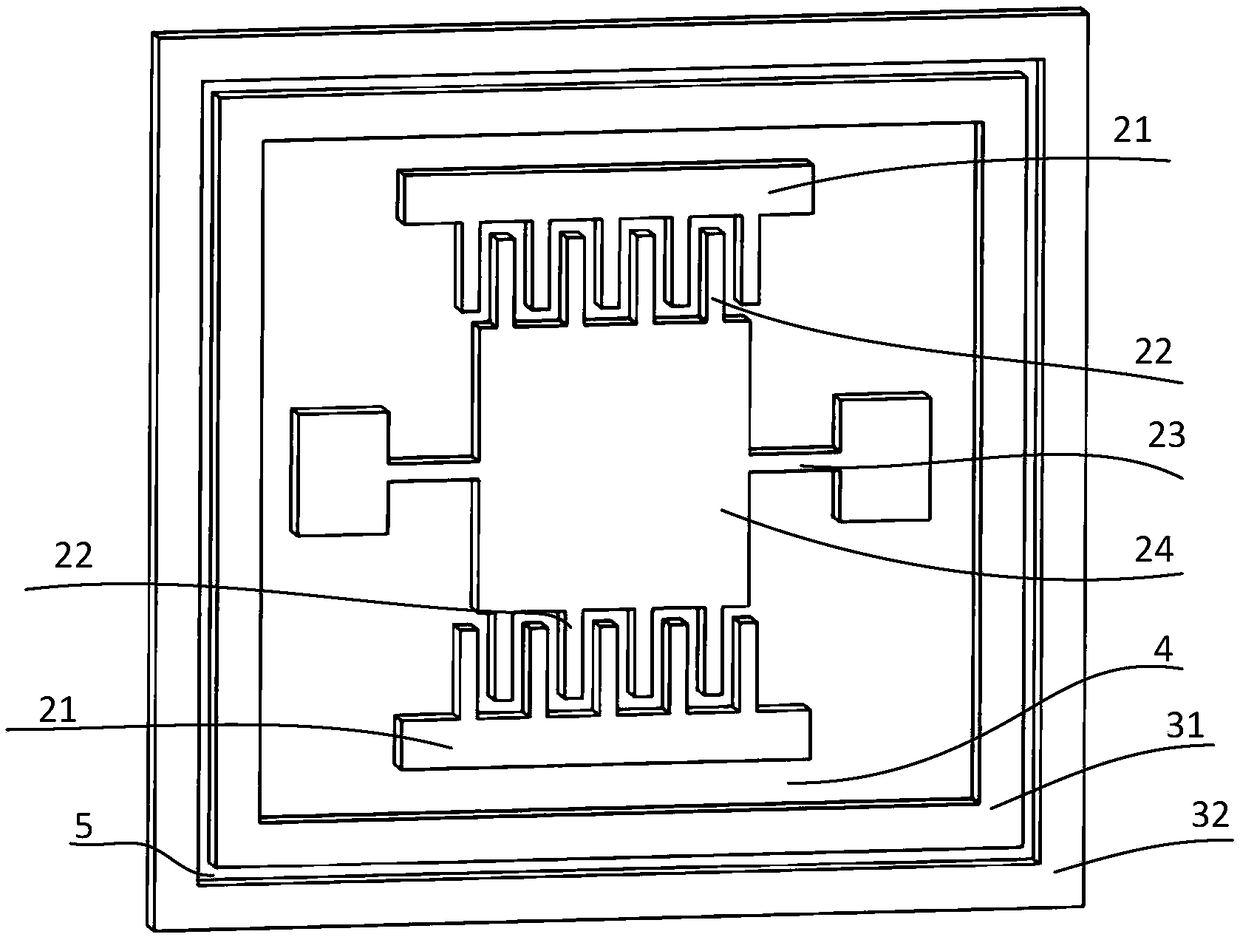

[0031] from figure 2 It can be seen that the driving comb 2 includes a static comb and its anchor point 21, a moving comb 22, a movable mass 24 connected to the moving comb 22, a movable beam supporting the movement of the movable mass 24 and its supporting anchor. Point 23. The pair of movable and static combs is used to drive the mass block 24 to move along a certain direction of the movable b...

Embodiment 2

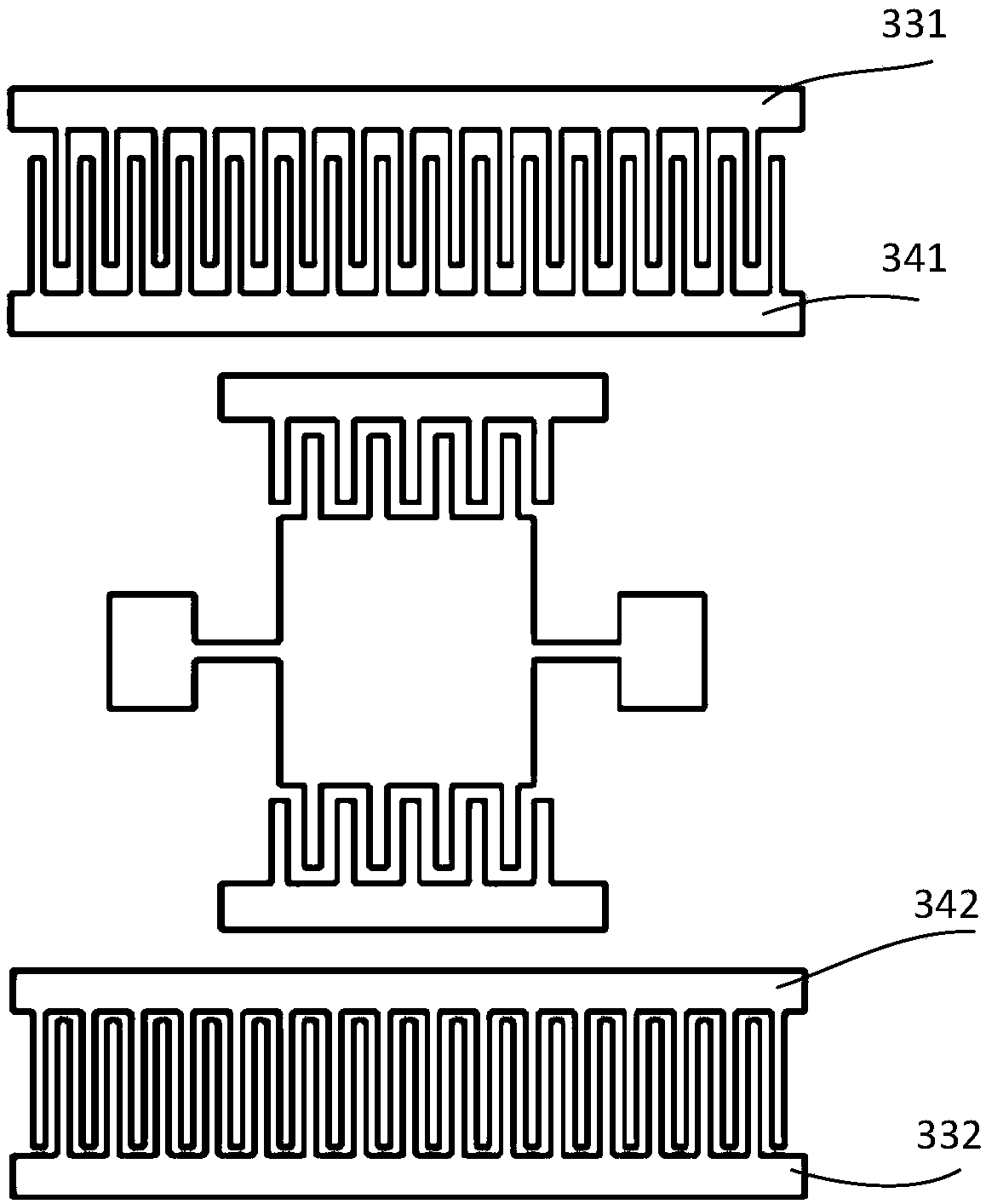

[0035] The shape of the two electrodes in the adsorption electrode electrode pair can be simple linear, wave linear, broken line, or staggered teeth, etc., from image 3 It can be seen that the difference between this embodiment and the first embodiment is that the adsorption electrode 3 in this embodiment includes two pairs of electrodes, and each pair of electrode pairs is a staggered tooth type (comb type), and the third electrode 331 is connected to the fourth electrode pair. The electrode 341, the fifth electrode 332, and the sixth electrode 342 are respectively used as two pairs of adsorption electrodes, and are arranged near the dynamic and static comb pairs of the comb driver to clean the particles. The toothed electrodes can increase the overlapping length of the two electrodes and increase the adsorption The effective adsorption area of the electrode improves the adsorption effect on particulate pollutants.

[0036] The height of the two electrodes of the adsorptio...

Embodiment 3

[0038] The difference between this embodiment and the second embodiment is that the adsorption electrode in this embodiment is a movable structure, such as Figure 5 As shown, the eleventh electrode 371 and the twelfth electrode 381, the thirteenth electrode 372 and the fourteenth electrode 382 are respectively used as adsorption electrode pairs, wherein the eleventh electrode 371 is supported by the first movable beam 61, and the first movable beam 61 The beam 61 is supported by the first support anchor point 71; the thirteenth electrode 372 is supported by the second movable beam 62, and the second movable beam 62 is supported by the second support anchor point 72; The second electrode 381, the thirteenth electrode 372 and the fourteenth electrode 382 apply specific signals to drive the eleventh electrode 371 and the thirteenth electrode 372 to move in a certain direction of the movable beam, and keep the eleventh electrode 371 and the The thirteen electrodes 372 are continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com