A method for improving mechanized harvesting traits of corn kernels

A corn and grain technology, applied in the agricultural field, can solve the problems of corn harvest yield loss, increase the difficulty of safe storage, increase drying costs, etc., and achieve the effect of improving mechanized harvesting level and field loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

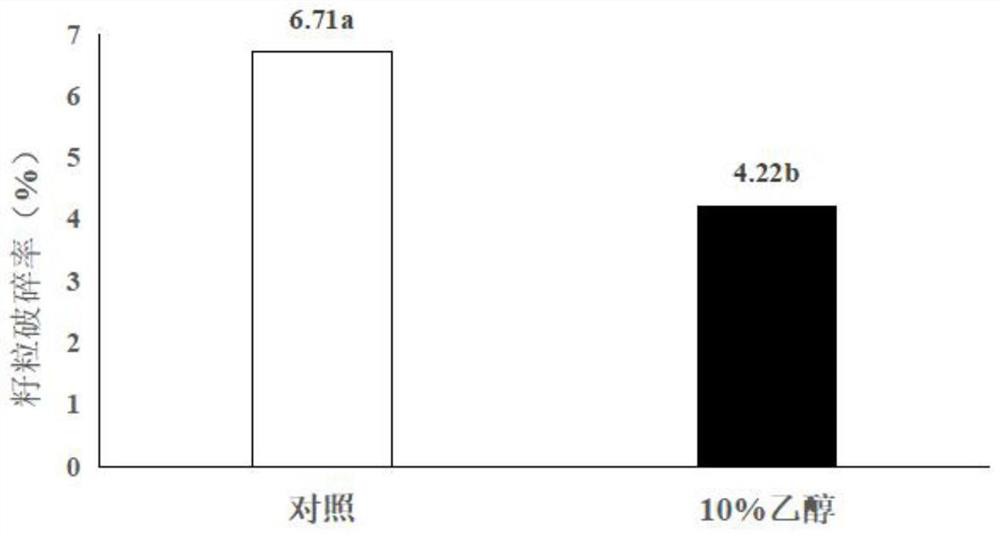

[0025] The corn planting density in the test area is 60000 plants / ha, and the row spacing is 60cm. The experiment adopts random block design, the treatment is to spray 10% ethanol solution, and the same amount of water is sprayed as the control. Spray on the 30th day after corn flowering and loose powder, the spraying time is from after 6:00 pm to before dark, the dosage per mu is 30kg, and the whole plant is sprayed when spraying. The area of the community is 667.7m 2 , each treatment repeated three times.

[0026] The 10% ethanol solution is prepared by mixing analytically pure ethanol and distilled water at a volume ratio of 1:9.

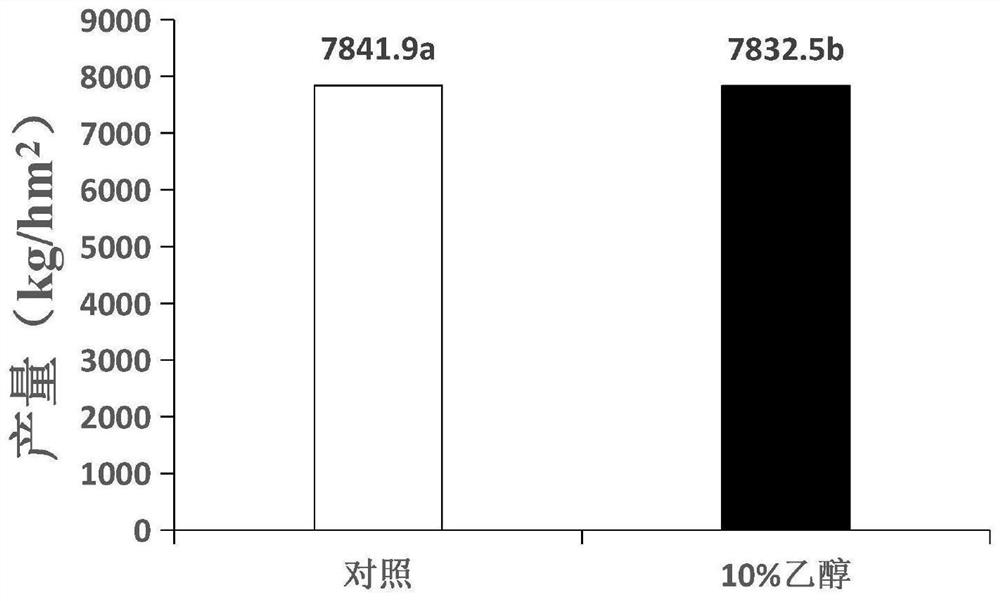

[0027] Yield

[0028] After the grains are mature, 400 plants are harvested in each plot, and the grain yield of 400 plants is measured after the grains are air-dried, and then the yield per unit area is converted according to the planting density.

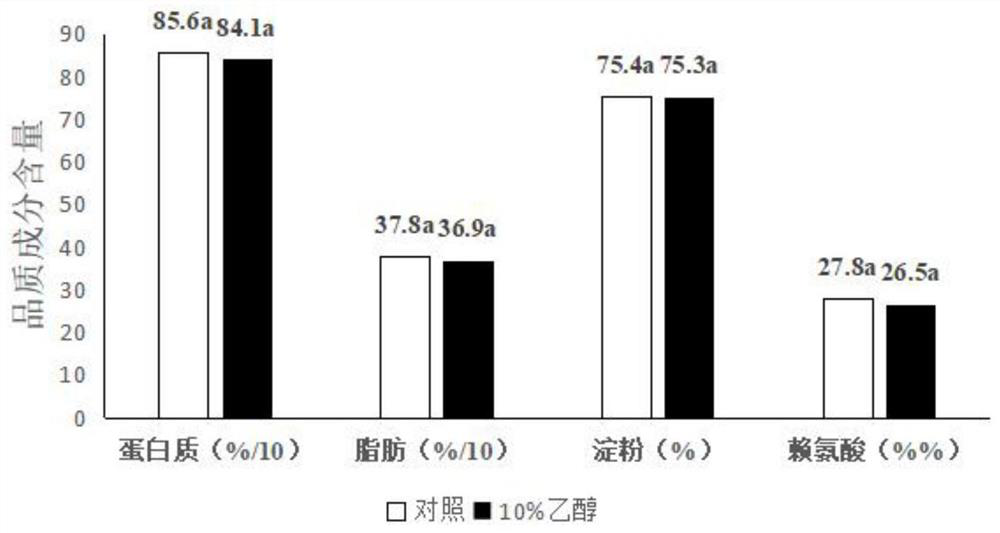

[0029] Grain Quality

[0030] Grain protein content was determined by Kjeldahl method; fat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com