A technology for preparing dried apples by combined drying with microwave and hot air

A technology that combines drying and microwave hot air is applied in the fields of fruit and vegetable preservation, fruit/vegetable preservation by dehydration, food science, etc. The softening time is prolonged and the drying effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing dried apples by combined drying with microwave and hot air, comprising the following steps:

[0036] (1) Ripe apples are peeled and cored and cut into apple slices with a thickness of 2 cm;

[0037] (2) Soak the apple slices in a color-protecting solution containing 0.4% citric acid and 0.5% calcium chloride for 3 hours;

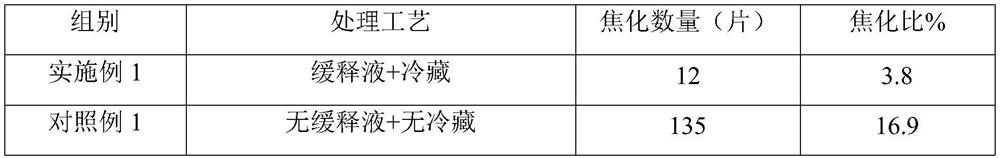

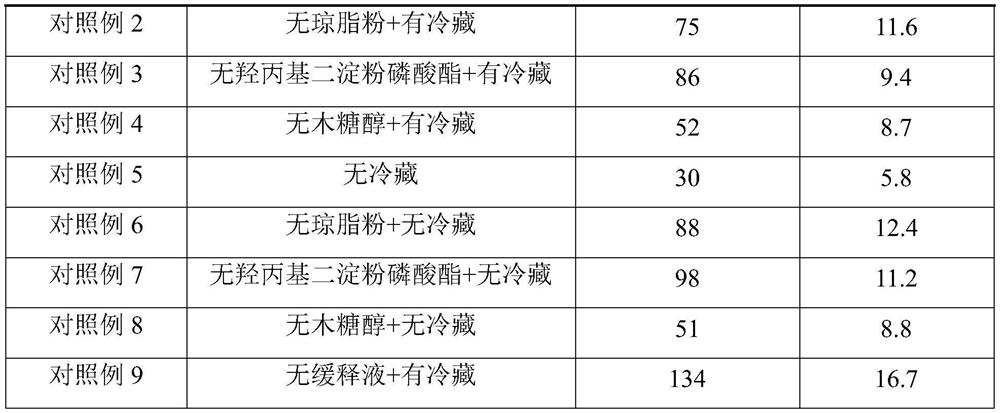

[0038] (3) Soak the apple slices in the slow-release solution for 20 minutes, refrigerate at 4°C for 1 hour after soaking, and then take 1000 pieces of uniform size for staged microwave drying and staged hot air drying; dry until the water content is low The dried apple product is obtained at 5%; the components of the sustained-release solution are: 3% agar powder, 6% hydroxypropyl distarch phosphate, and 6% xylitol.

[0039]The staged microwave drying process includes:

[0040] Use 900W microwave power to dry for 2 minutes; use 600W microwave power to dry for 3 minutes; use 300W microwave power to dry for 4 minutes; microwave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com