cleaning equipment

A technology for cleaning equipment and filter components, applied in cleaning equipment, vacuum cleaners, household appliances, etc., can solve the problems of reduced dust removal efficiency, reduced suction power of vacuum cleaners, blocked air ducts, etc., to improve dust removal effect, improve service life, and reduce operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

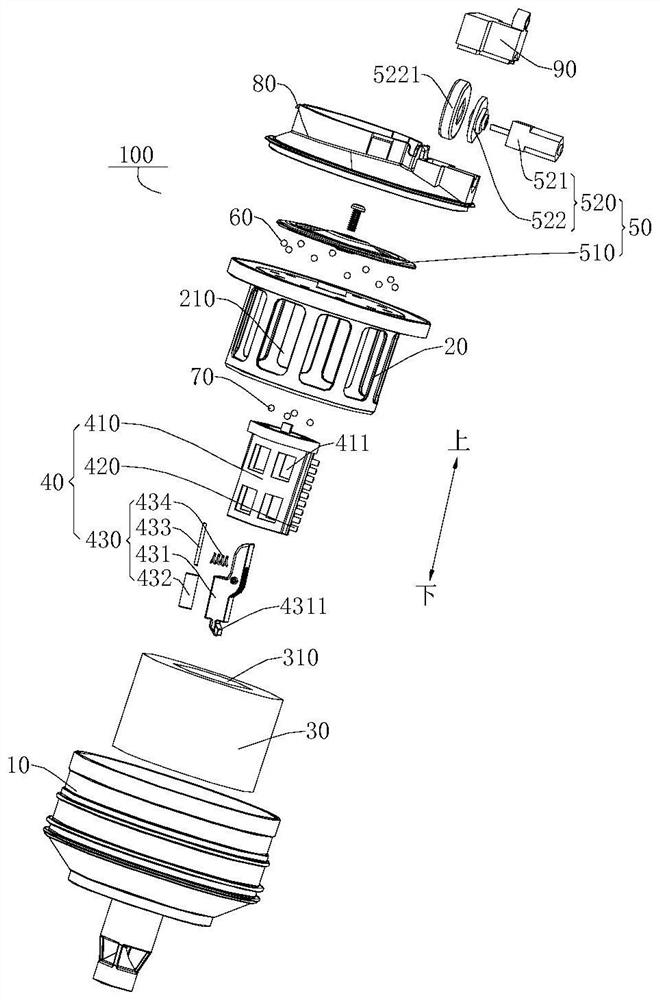

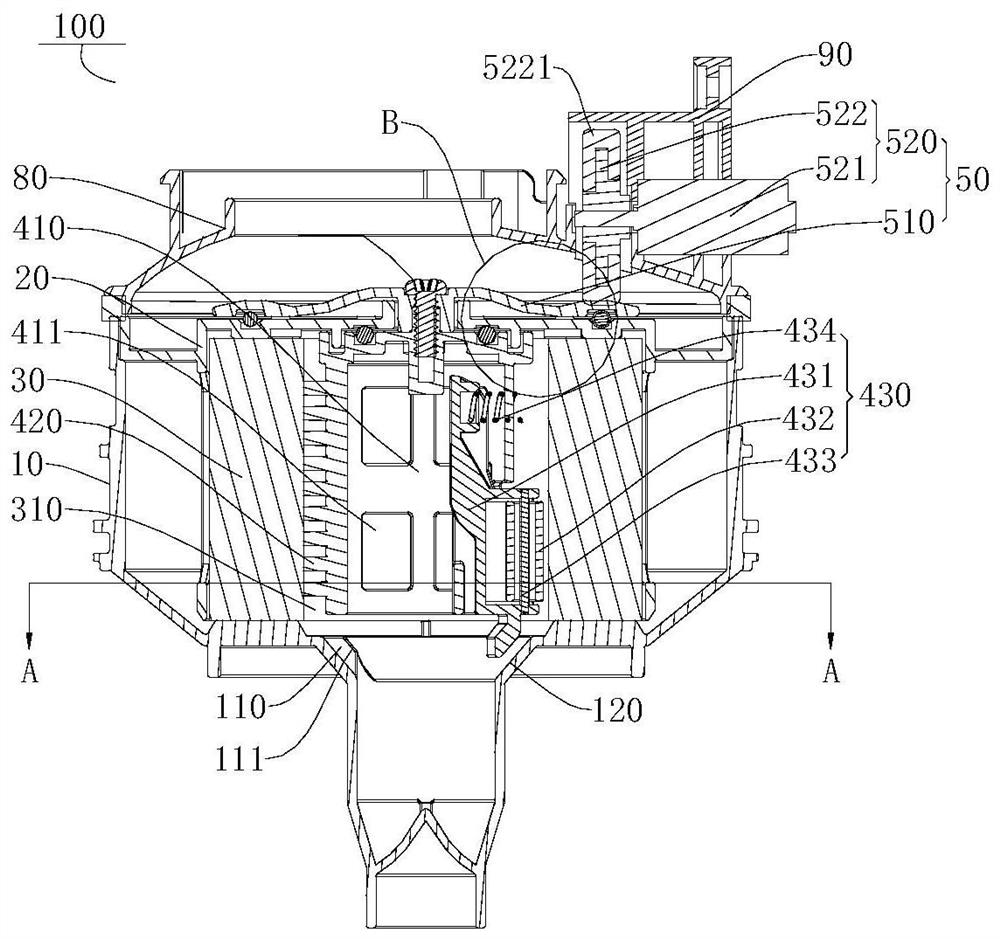

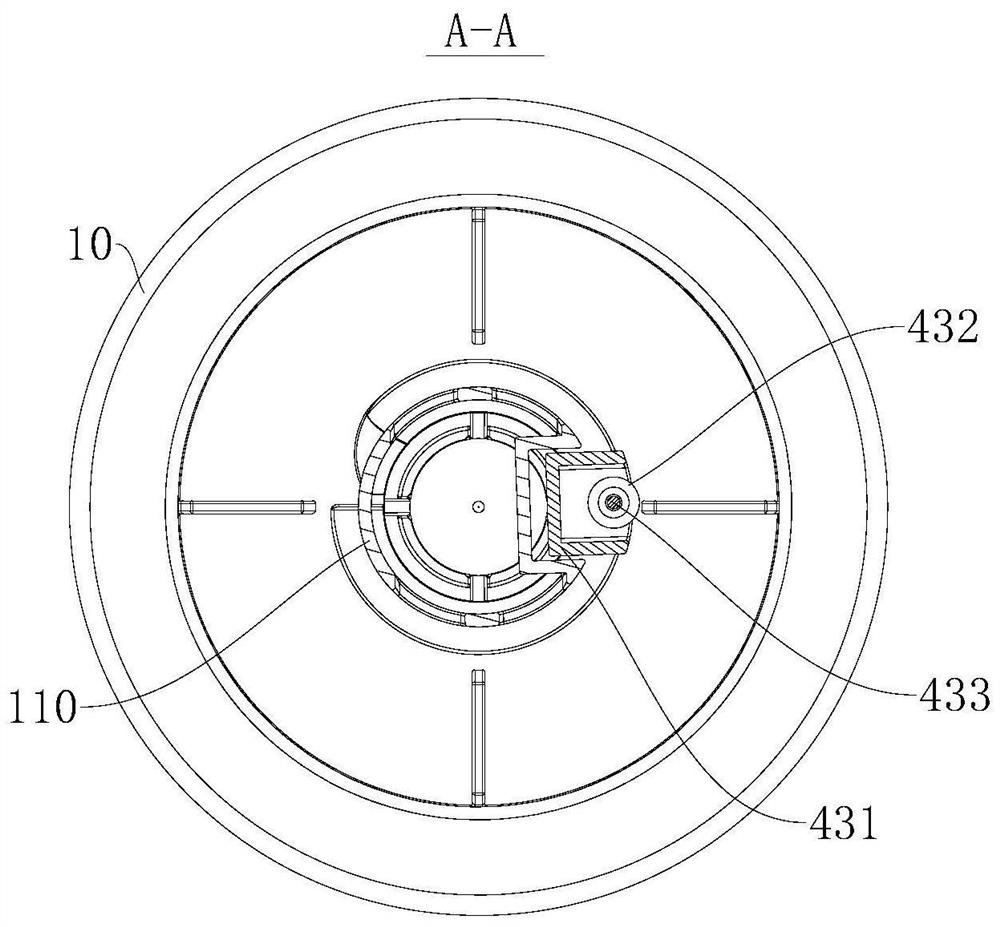

[0081] like Figure 1-Figure 8 , Figure 10-Figure 12 As shown, the cleaning device 100 may be a vacuum cleaner, and the cleaning device 100 includes: a body 10 , a bracket 20 , a filter assembly 30 , a dust removal assembly 40 , a trigger 110 and a drive assembly 50 .

[0082] Among them, such as figure 1 , figure 2 and Figure 12 As shown, there is a dust and gas separation system 130 inside the machine body 10, and the dust and gas separation system 130 can be a single-cone or multi-cone separator for separating and removing dust from the airflow. The dust and gas separation system 130 includes a conical part 120, the cross-sectional area of the conical part 120 gradually decreases in the direction from top to bottom, and a trigger 110 is provided on the inner wall of the conical part 120, and the trigger 110 has a second Match the bevel 111.

[0083] like figure 1 and figure 2 As shown, the bracket 20 is disposed in the body 10. The bracket 20 has an annular out...

Embodiment 2

[0094] like Figure 9 As shown, the difference from Embodiment 1 is that in this embodiment, the driving wheel 522 is a gear, and the driving disc 510 is provided with a rack 511 matching the gear. The cooperation between the gear and the rack 511 can improve the firmness and reliability of the cooperation between the driving wheel 522 and the driving disc 510 . Moreover, the transmission ratio between the drive wheel 522 and the drive disc 510 can be calculated and designed according to the rotation speed requirement of the dust removal assembly 40 , which improves the stability and reliability of the operation of the dust removal assembly 40 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com