Novel railhead refining forging machine

A technology of precision forging and rail head, applied in the field of forging presses, can solve the problems of good shock absorption effect and high degree of automatic precision forging of rail head precision forging presses, and achieve good shock absorption effect, high degree of automatic precision forging and reduced noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

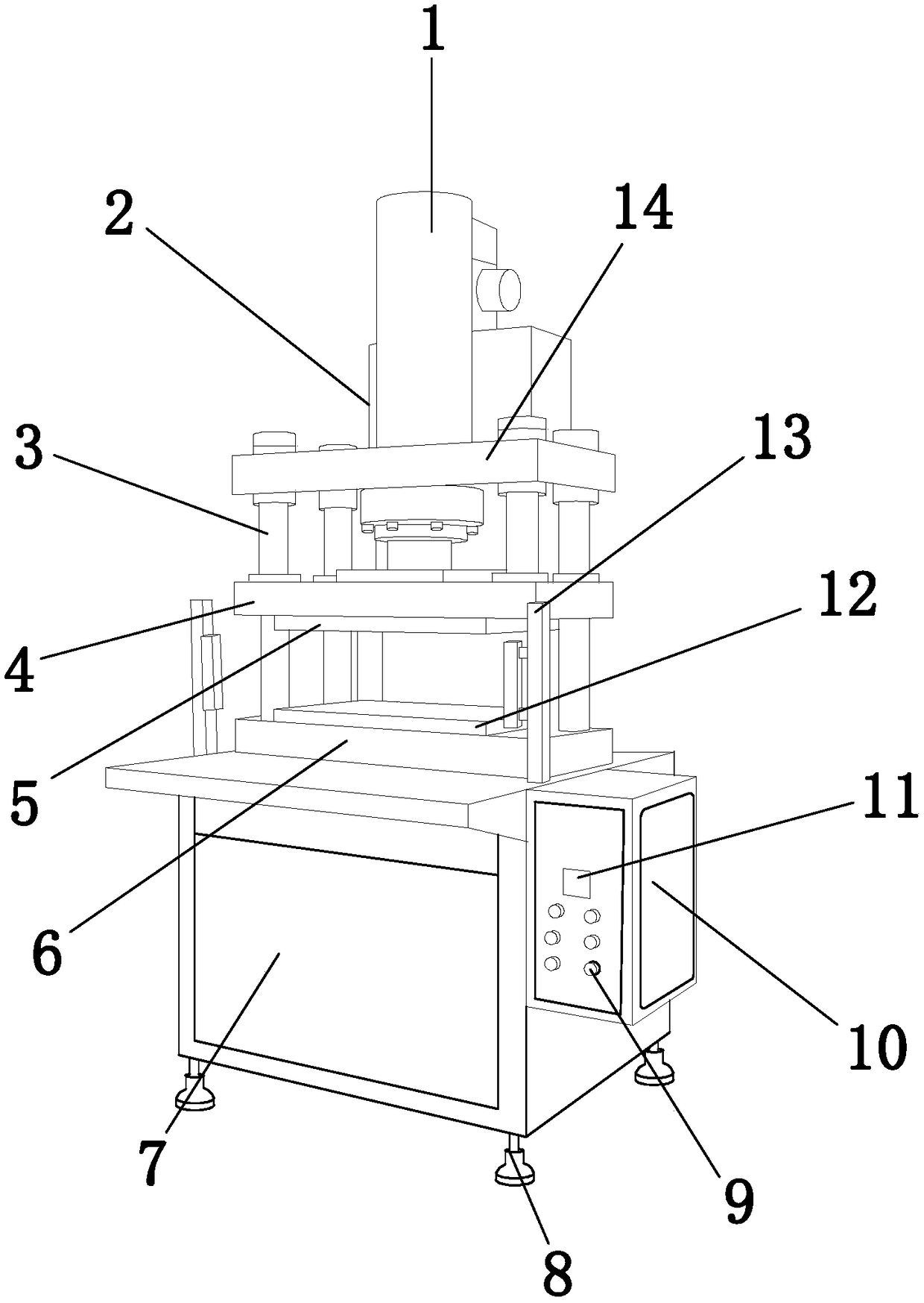

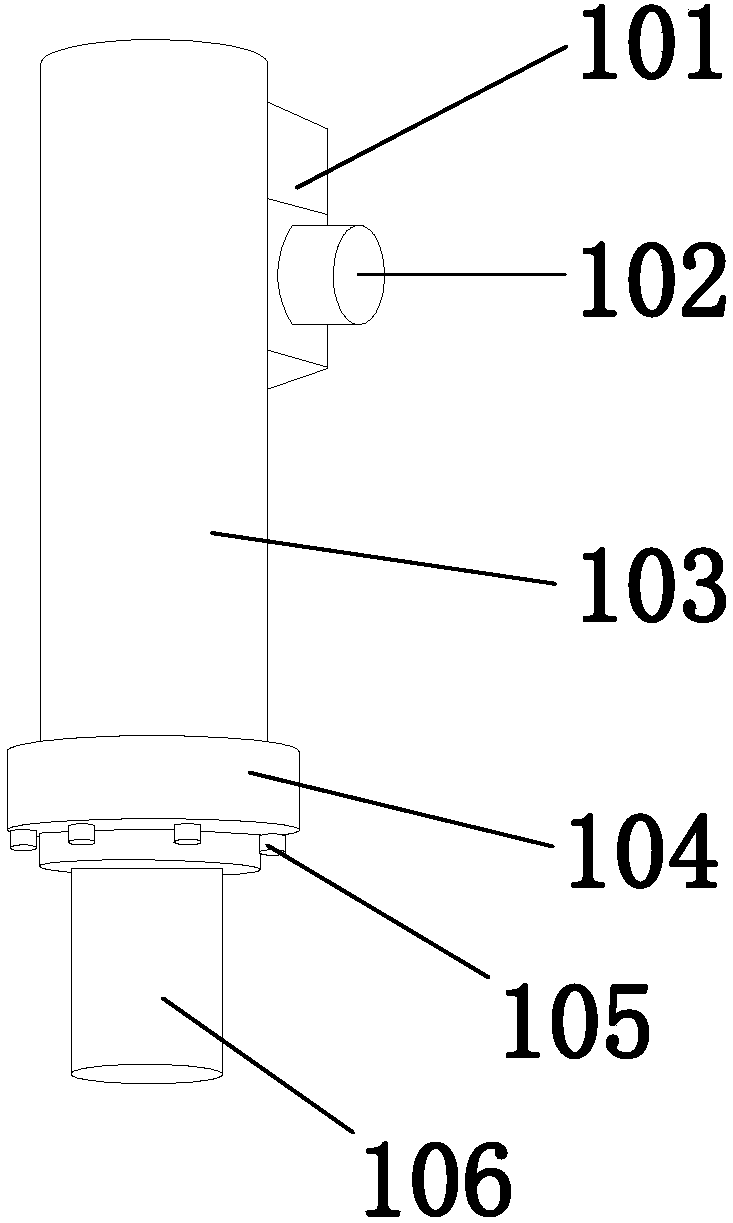

[0019] see figure 1 and figure 2 , the present invention provides a new rail head precision forging press: its structure includes an oil cylinder 1, a hydraulic oil tank 2, a column 3, a lifting platform 4, a precision forging briquetting block 5, a fixed platform 6, an operating platform 7, a shock-absorbing foot 8, an operating Button 9, control cabinet 10, display screen 11, mold table 12, photoelectric protector 13, top plate 14; described top plate 14 is a rectangular top, is provided with four columns 3 evenly and equidistantly, and described column 3 is vertically fixed on On the top plate 14, the top plate 14 passes through the lifting platform 4 through the column 3 and connects with the fixed platform 6 to form a rectangular structure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com