Self-positioning welding line tracking device for boiler tube welding

A tracking device and self-positioning technology, applied in applications, home appliances, welding equipment, etc., can solve problems such as affecting physical health, deepening worker fatigue, and difficult to discharge welding waste gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

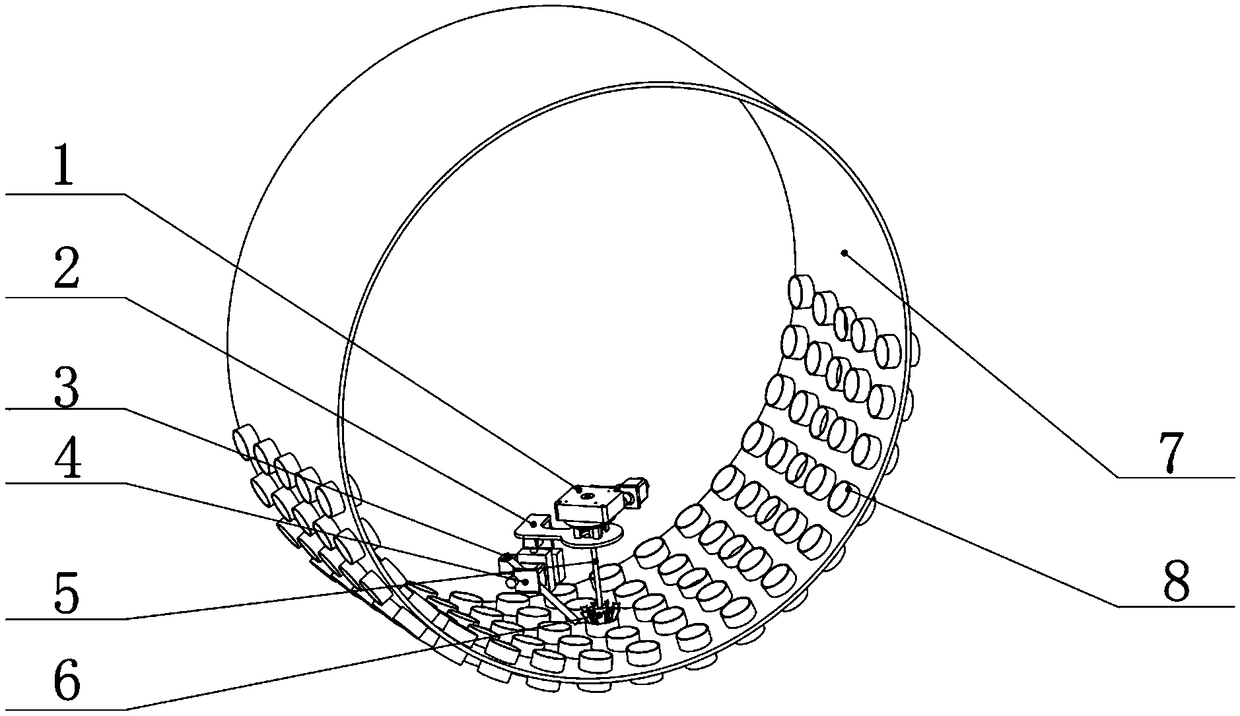

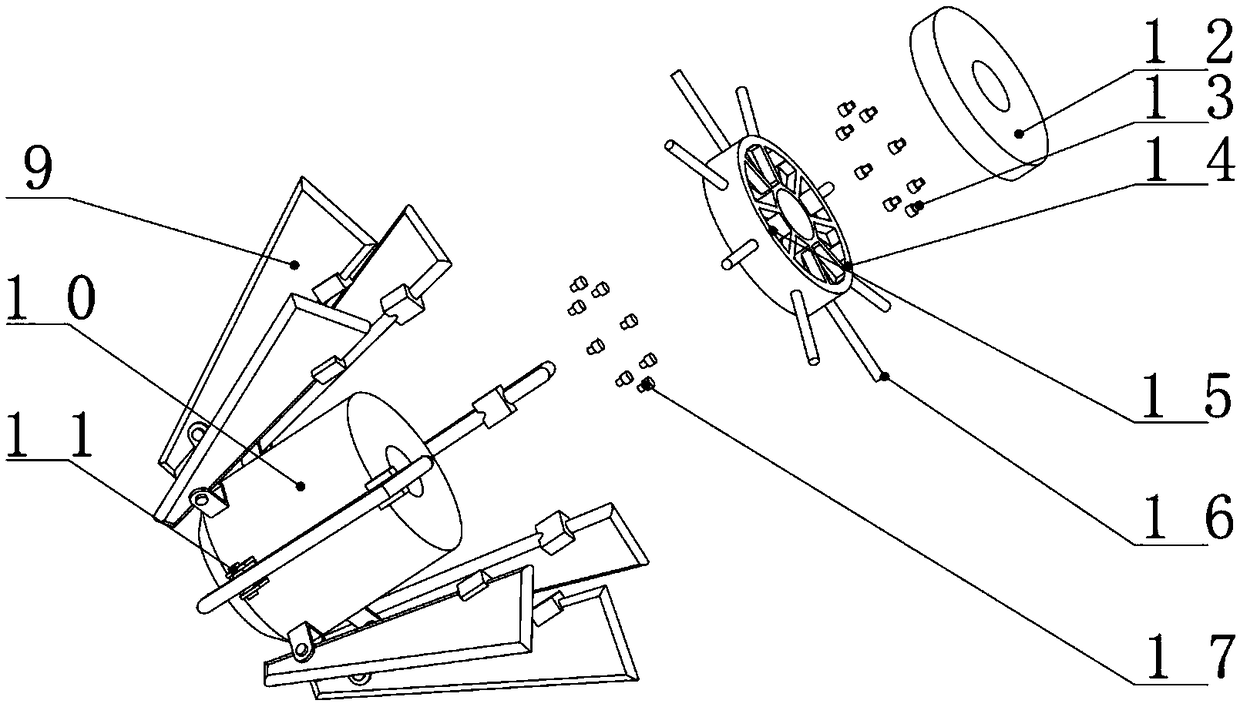

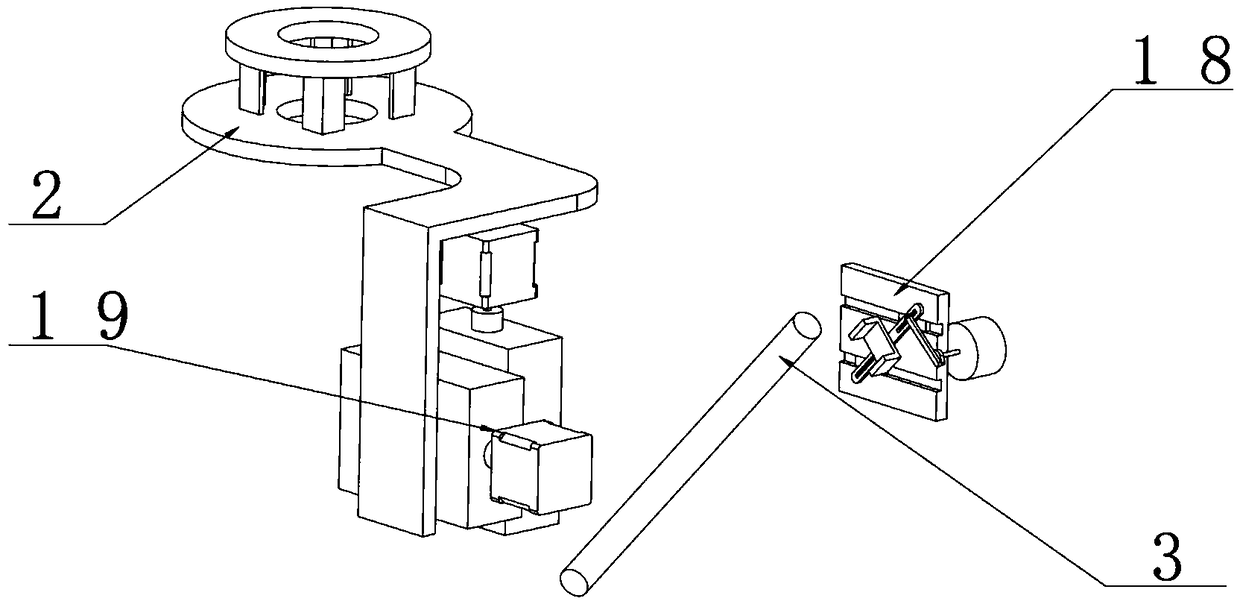

[0027] In order to better express the technical solutions and beneficial effects of the entire invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation cases. However, the embodiments of the present invention are not limited thereto.

[0028] The invention discloses a self-positioning seam tracking device for boiler tube welding. The positioning force sensor structure of the device includes: 9-ceramic pressing piece, 10-bracket, 11-hinge, 12-upper cover , 13-phototransistor, 14-circular plate, 15-spring, 16-connecting rod, 17-light-emitting diode; the specific steps for adjusting the positioning force sensor are:

[0029] Step 1: The camera acquires the image information of the convection tube 8 , and the center of the convection tube 8 is obtained through image processing, and the mechanical arm drives the positioning rod 5 to move in the direction of the convection tube 8 .

[0030] Step two,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com