Mecanum wheel omni-directional mobile trolley with adaptive adjustment of gear train and method thereof

An adaptive adjustment, omnidirectional movement technology, applied in the direction of motor vehicles, wheels, vehicle parts, etc., can solve the problems of reducing the execution accuracy of the robot arm and the function failure of the robot arm, and achieve the effect of avoiding slippage and moving accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings.

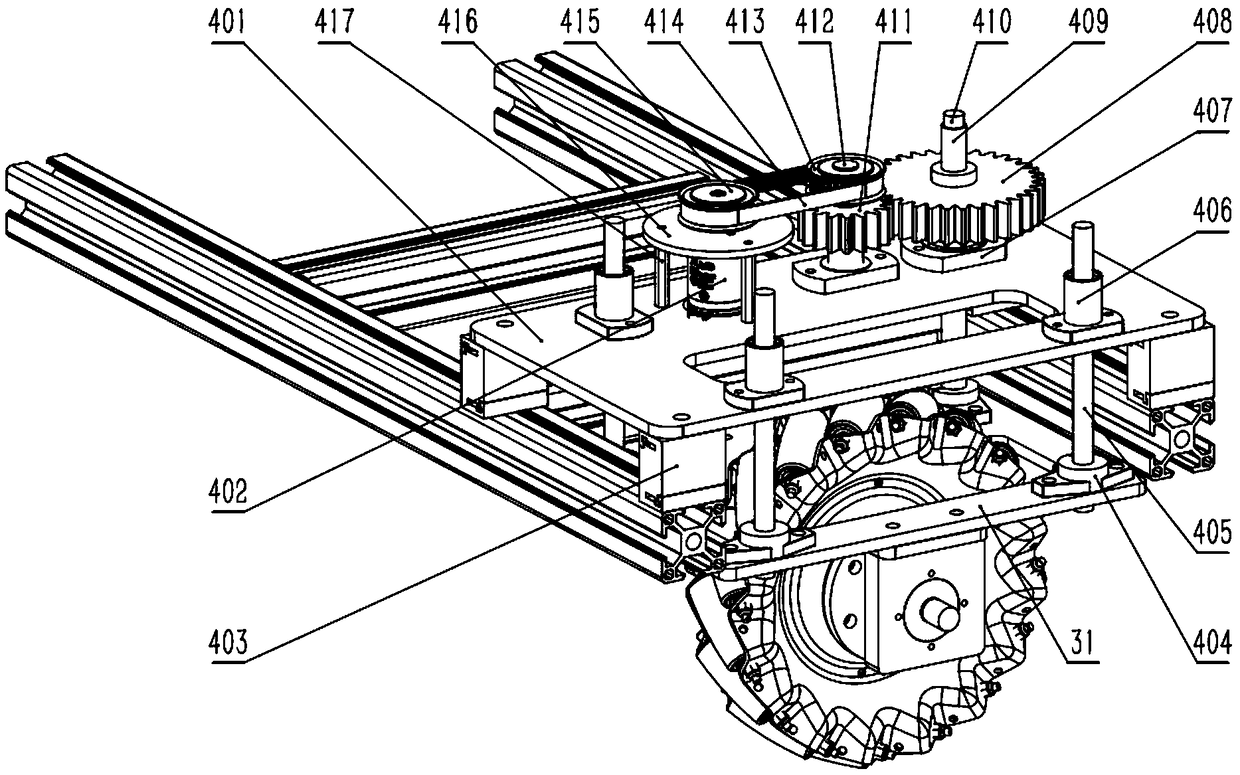

[0030] like figure 1 As shown, the main body of the mobile trolley is the body frame 1, and the four corners of the body frame 1 are equipped with Mecanum wheel trains, wherein the three Mecanum wheel trains in the triangle are fixed on the bottom of the body frame 1, and the other corners are fixed on the bottom of the body frame 1. A Mecanum wheel train is fixed on the bottom of the body frame 1 through the wheel train adaptive adjustment mechanism.

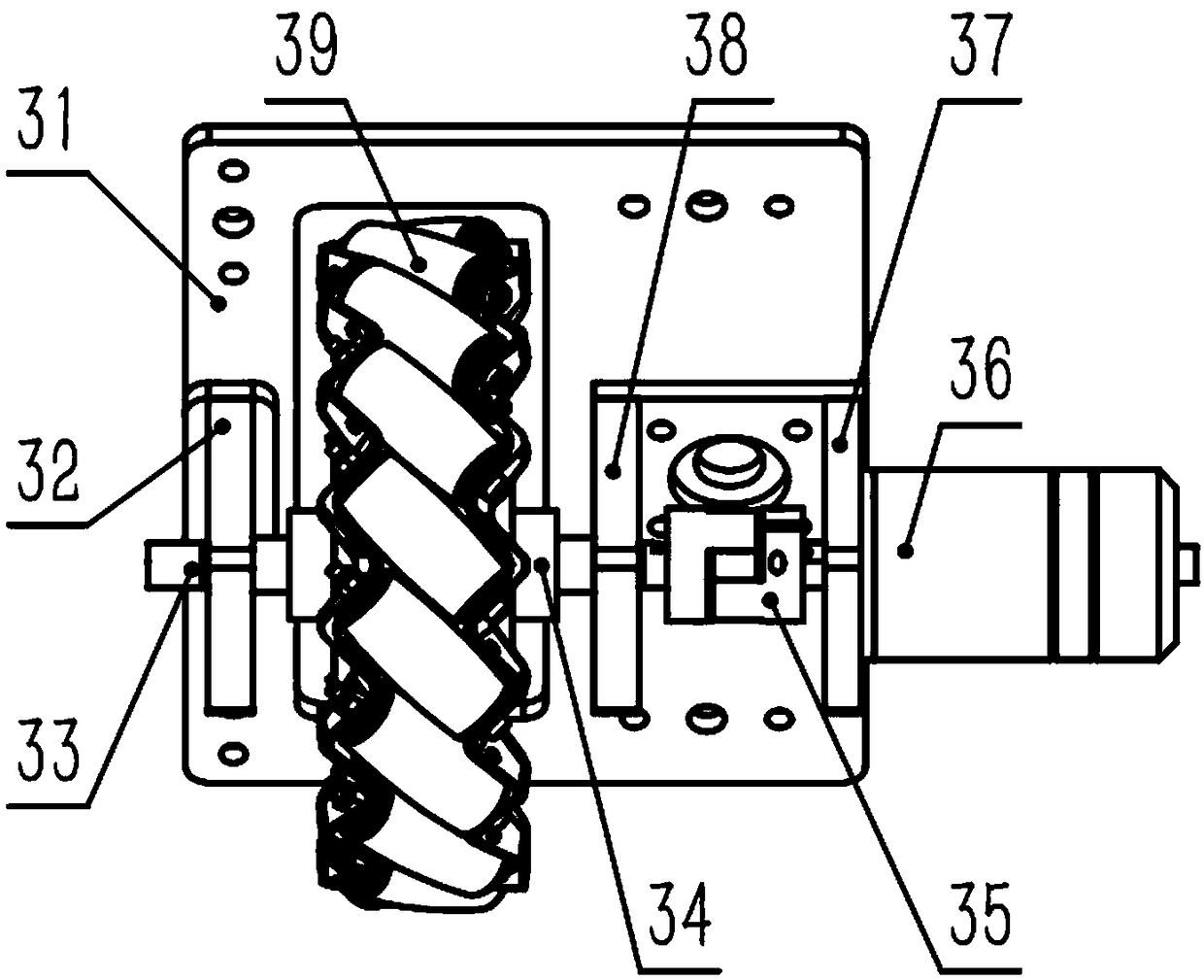

[0031] like figure 2 As shown, the Mecanum wheel train includes a wheel train fixing plate 31 and an auxiliary belt seat bearing 32, an active belt seat bearing 38 and a motor seat 37 installed on the wheel train fixing plate 31. The Mecanum wheel train passes through The wheel train fixing plate 31 is installed in cooperation with the body frame 1. A through slot is provided in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com