A thrust converter for a pulse detonation engine

A pulse detonation and engine technology, applied in mechanical equipment, power plant types, power plant construction, etc., can solve problems such as narrowing the stable working range of the engine, easy fatigue of materials, and reduced working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

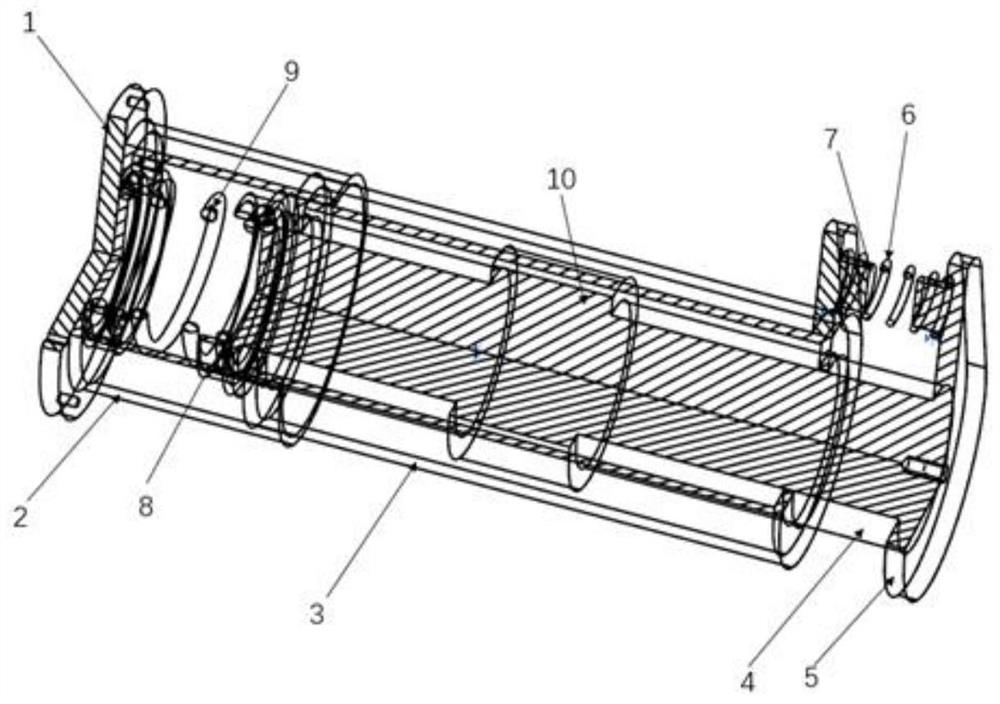

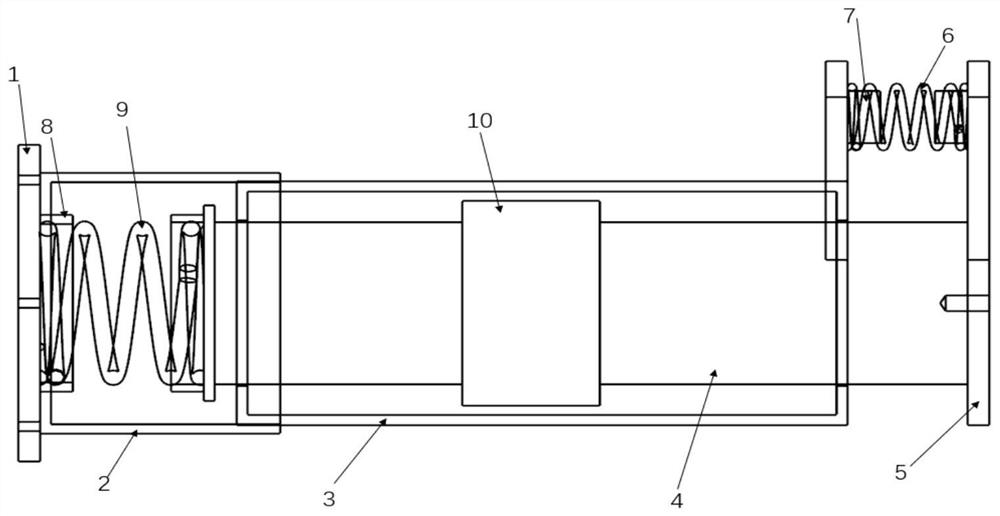

[0034] refer to figure 1 and figure 2 , a thrust converter of a pulse detonation engine of the present invention includes an aircraft mounting seat 1, a spring cavity 2, a linear viscous damper, an engine mounting seat 5, a parallel spring 6 and a series spring 9; The damping oil cylinder 3, the piston rod 4 and the piston 10 are installed coaxially. The damping oil cylinder 3 is a hollow cylindrical structure with a through hole in the center of both ends. The piston rod 4 is installed through the two through holes; the piston 10 is installed The outer peripheral surface of the center position of the piston rod 4 is in clearance fit with the inner surface of the damping cylinder 3;

[0035] One end of the linear viscous damper is fixed on the aircraft mount 1 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com