Multi-element doped carbon nanotube array modified carbon fiber and its preparation method and application

A carbon nanotube array and nanotube array technology, which is applied in the field of nitrogen, boron, and phosphorus multi-element doped three-dimensional porous carbon nanotube arrays to modify carbon fibers and its preparation. Various elements and other issues, to achieve the effect of improving catalytic activity, simple doping process, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

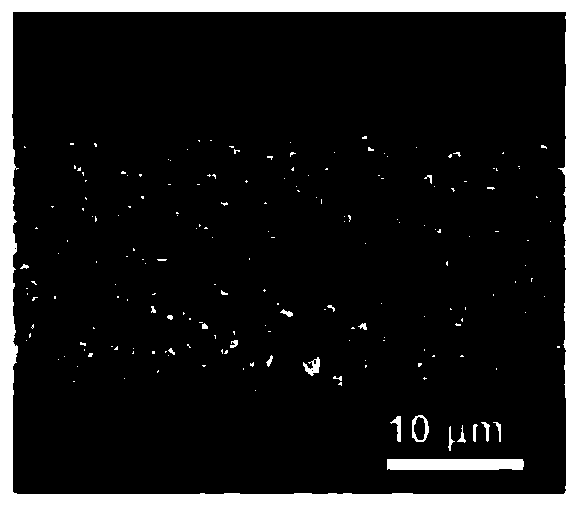

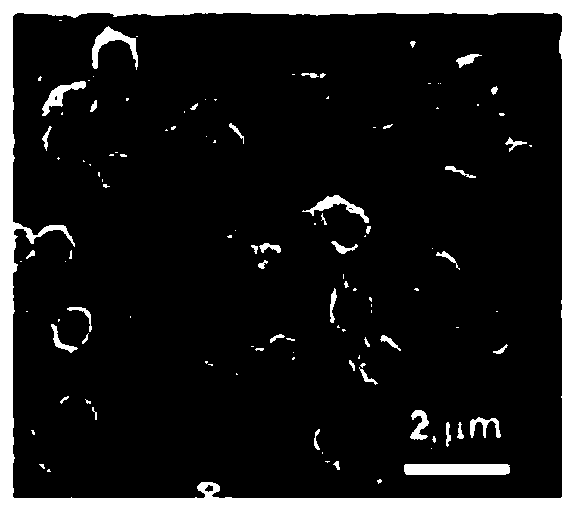

Embodiment 1

[0036] (1) Electrodeposition preparation of zinc oxide nanorod array templates on carbon fibers: Activate the carbon fibers: place the carbon fibers in 15% hydrogen peroxide aqueous solution at 40° C. for 24 hours. Prepare the electrolyte solution: weigh a certain amount of zinc nitrate and dissolve it in 100 mL of deionized water, gradually add ammonia water to adjust the pH of the solution to 9. Two-electrode system galvanostatic electrodeposition of hexagonal prismatic zinc oxide nanorod arrays, the zinc rods as the reference electrode and the counter electrode, the current density is -0.0008A cm-2. First, the carbon fiber is used as the working electrode, and the carbon fiber with zinc oxide seeds is obtained by electrodeposition at 20°C; then, the obtained carbon fiber with zinc oxide seeds is used as the working electrode, and the carbon fiber with zinc oxide seeds is obtained by electrodeposition at 80°C. rods of carbon fibers, namely ZnO nanorod arrays / carbon fiber com...

Embodiment 2

[0040] (1) Electrodeposition preparation of zinc oxide nanorod array templates on carbon fibers: Activate the carbon fibers: place the carbon fibers in 15% hydrogen peroxide aqueous solution at 40° C. for 36 hours. Prepare the electrolyte solution: weigh a certain amount of zinc nitrate and dissolve it in 100 mL of deionized water, gradually add ammonia water to adjust the pH of the solution to 10. Two-electrode system galvanostatic electrodeposition of hexagonal prismatic zinc oxide nanorod arrays, the zinc rods are the reference electrode and the counter electrode, and the current density is -0.0008A cm -2 . First, the carbon fiber is used as the working electrode, and the carbon fiber with zinc oxide seeds is obtained by electrodeposition at 20°C; then, the obtained carbon fiber with zinc oxide seeds is used as the working electrode, and the carbon fiber with zinc oxide seeds is obtained by electrodeposition at 80°C. rods of carbon fibers, namely ZnO nanorod arrays / carbon ...

Embodiment 3

[0044] (1) Electrodeposition preparation of zinc oxide nanorod array templates on carbon fibers: Activate the carbon fibers: place the carbon fibers in 20% hydrogen peroxide aqueous solution at 40° C. for 48 hours. Preparation of electrolyte solution: Weigh a certain amount of zinc nitrate and dissolve it in 100 mL of deionized water, gradually add ammonia water to adjust the pH of the solution to 11. Two-electrode system galvanostatic electrodeposition of hexagonal prismatic zinc oxide nanorod arrays, the zinc rods are the reference electrode and the counter electrode, and the current density is -0.0008A cm -2 . First, the carbon fiber is used as the working electrode, and the carbon fiber with the zinc oxide seed is grown by electrodeposition at a temperature above 20°C; then, the obtained carbon fiber with the zinc oxide seed is used as the working electrode, and the carbon fiber with the zinc oxide seed is grown by electrodeposition at a temperature above 80°C. Carbon fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com