Actuator assembly for a transmission shifter

A technology for transmissions, actuators, applied in the direction of transmissions, elements with teeth, transmission controls, etc., which can solve the problems of loss, units cannot be located in the desired position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

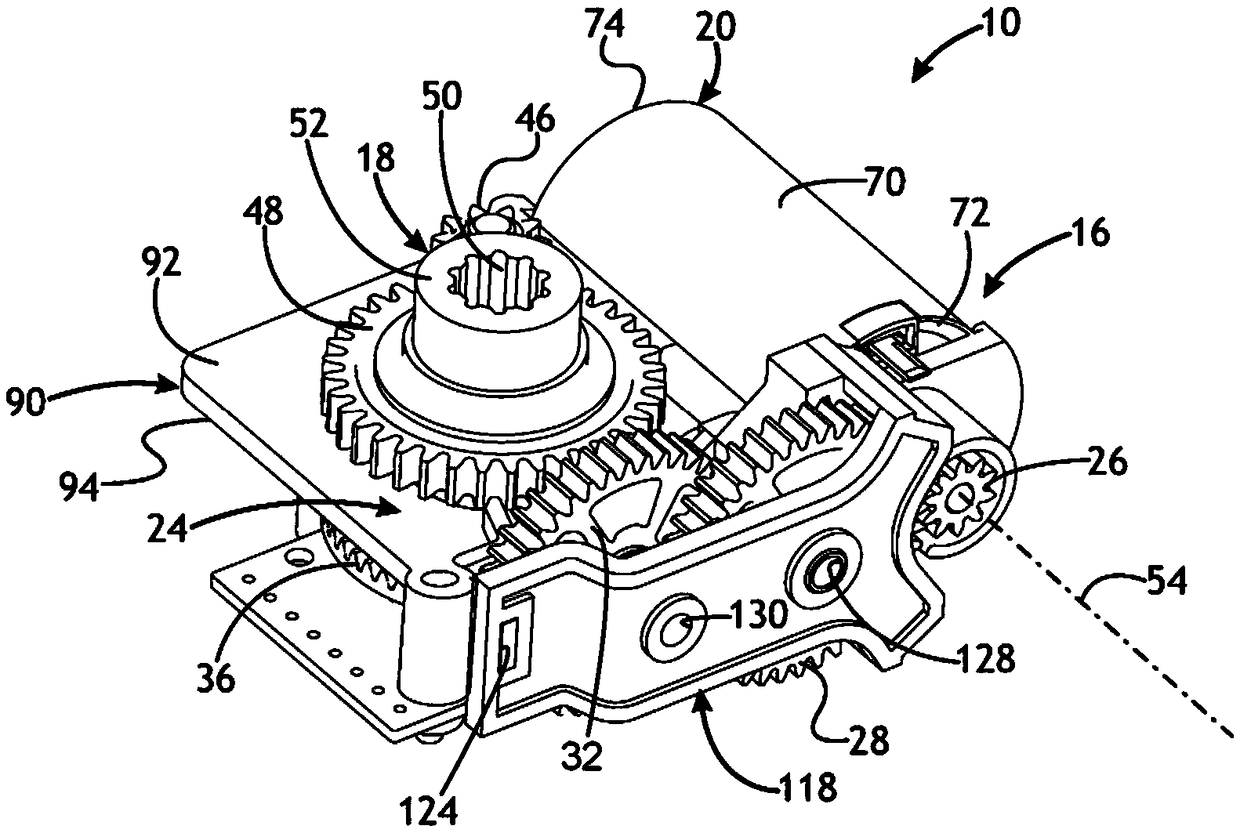

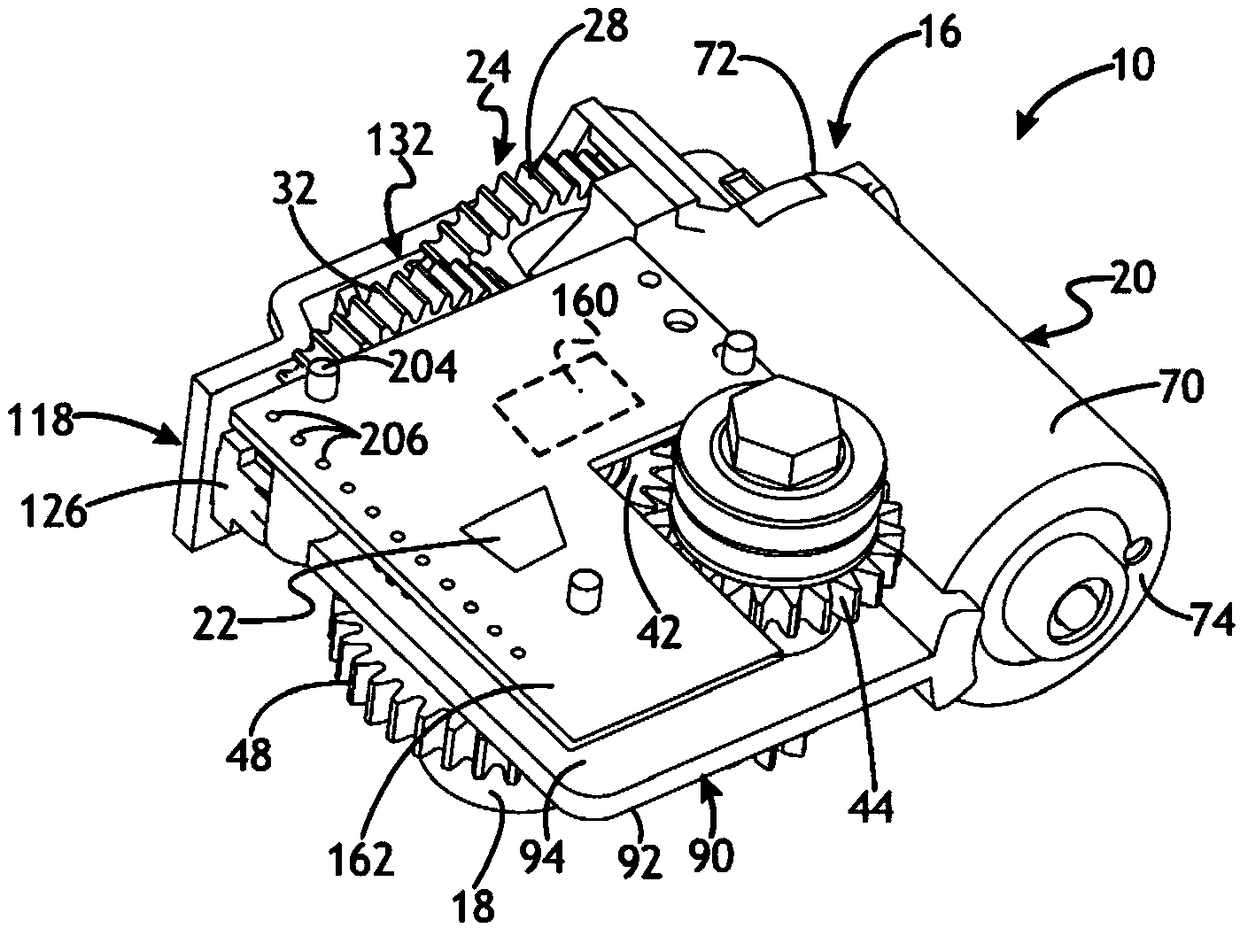

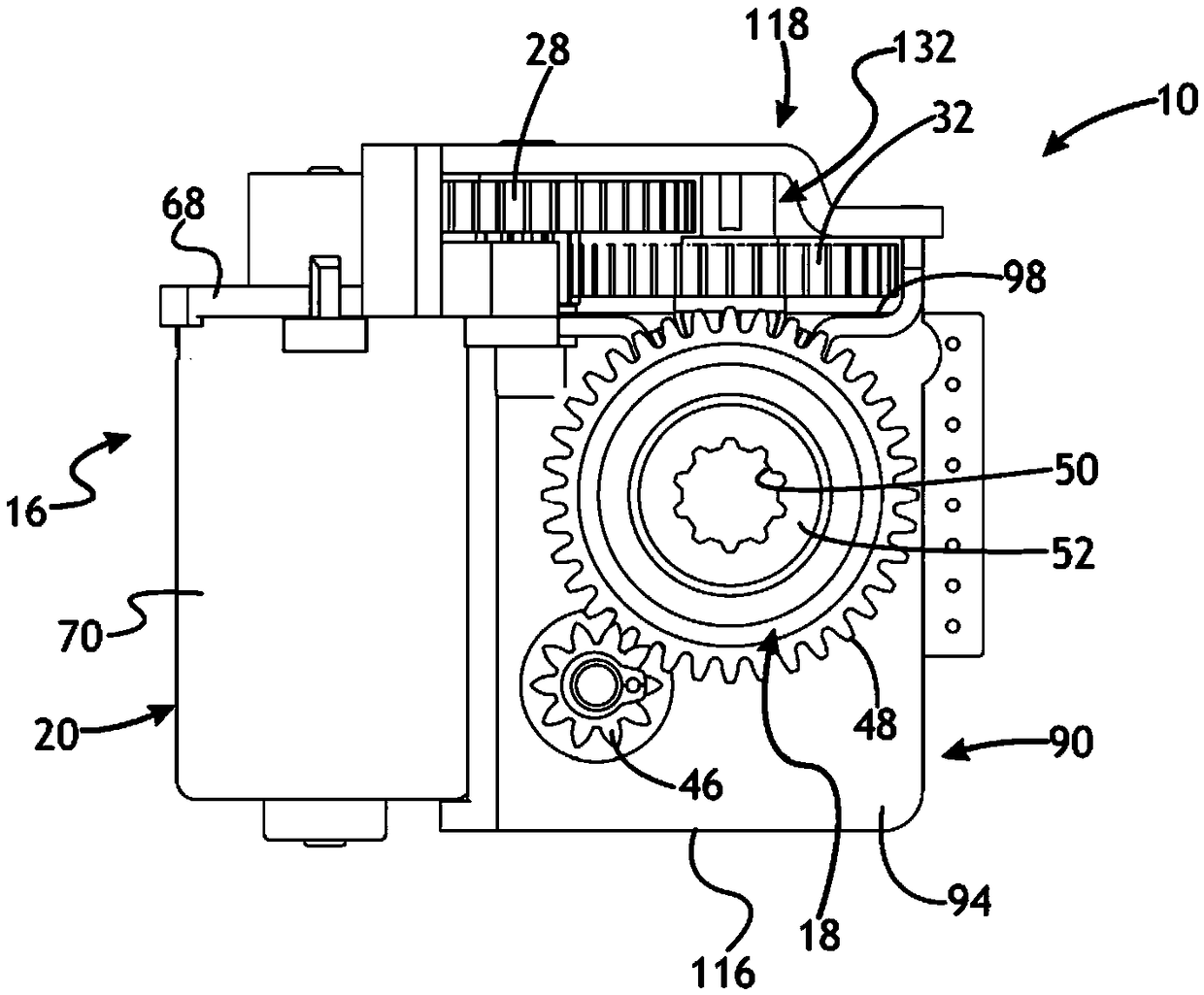

[0026] Referring to the accompanying drawings in more detail, Figure 1 to Figure 6 Shown is a shift actuator assembly 10 which is controlled by a driver-operated shift mechanism to effect shifting of the transmission, for example, shifting the transmission between Park, Neutral, Reverse, and Drive . The shift actuator assembly 10 may be part of a so-called "shift-by-wire" system in which an operator command to shift gears (for example, by turning a rotary shift knob or moving a shift lever or other shifter) is transmitted to the main drive 16 of the assembly, which is drivingly coupled to the transmission shift lever (in Figure 4 The output mechanism 18 shown schematically with 14 in the center is used to switch between the transmission gears. The actuator assembly 10 may also be used in other vehicle systems that require a rotary or linear output, such as a parking lock system, valve controller, or locking mechanism.

[0027] exist Figure 1 to Figure 6 The actuator ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com