Experimental device for testing performance of microfluid inertia impact filter

An inertial impact and experimental device technology, which is applied in the direction of measuring devices, scientific instruments, suspensions and porous material analysis, etc., can solve the problems of high outlet pressure aerosol, difficult to control powder output, large powder output, etc., to achieve reduction Small experimental error, convenient disassembly and cleaning, and the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments will be described in detail below in conjunction with the accompanying drawings.

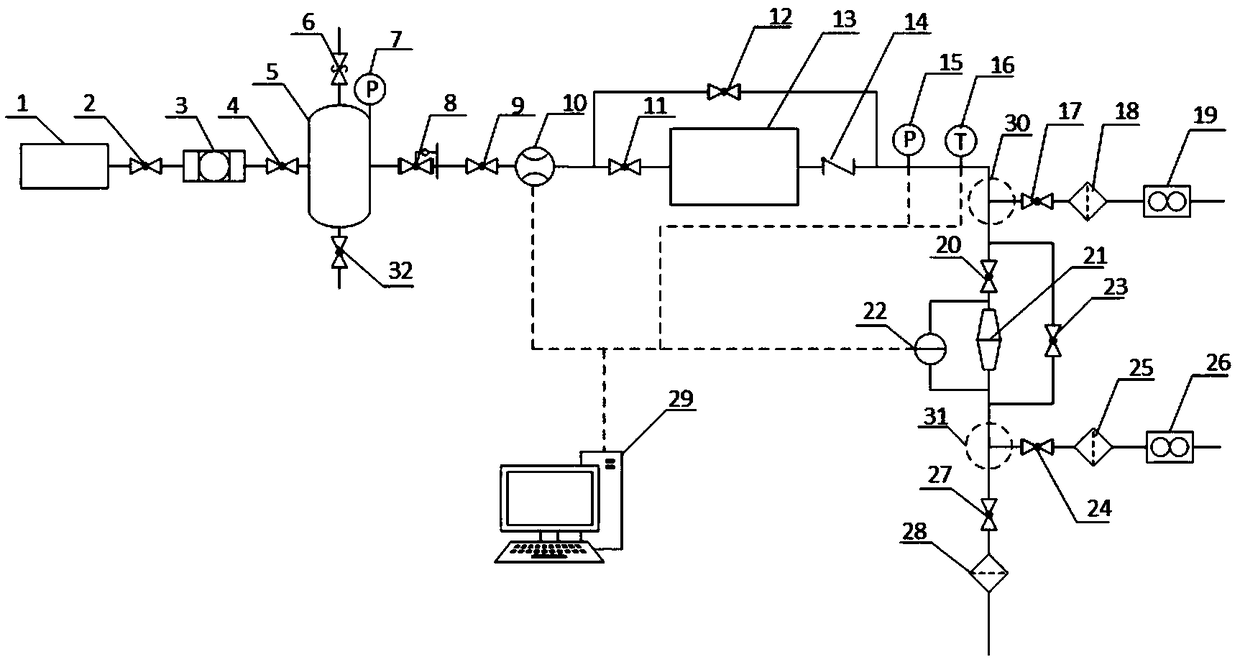

[0031] Such as figure 1 As shown, the experimental device is mainly composed of a clean air part, an aerosol distribution part, a filter part, a sampling part, a data acquisition part, and pipes and valves connecting each device. The outlet of the clean air part is connected to the inlet of the aerosol distribution part. , the outlet of the aerosol part is connected with the inlet of the filter part, the outlet of the filter part is directly connected to the atmosphere, and the inlet and outlet sampling parts are respectively connected to the inlet and outlet of the microfluid inertial impact filter.

[0032] Such as figure 1 As shown, the clean air part is mainly composed of an air compressor 1, a compressed air filter 3, and an air storage tank 5 connected in sequence. The air compressor 1 is connected with the compressed air filter 3 through the ball valve 2, the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com