Method and device for calibrating ultrasonic water-immersed piezoelectric probe

A technology of electric probe and ultrasonic water, applied in the direction of measuring device, material analysis using sound wave/ultrasonic wave/infrasonic wave, instrument, etc., can solve the problems of probe sensitivity measurement result error, signal distortion, etc., to eliminate circuit impedance mismatch, eliminate The effect of the limitation of the detection distance and the simplicity of the experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

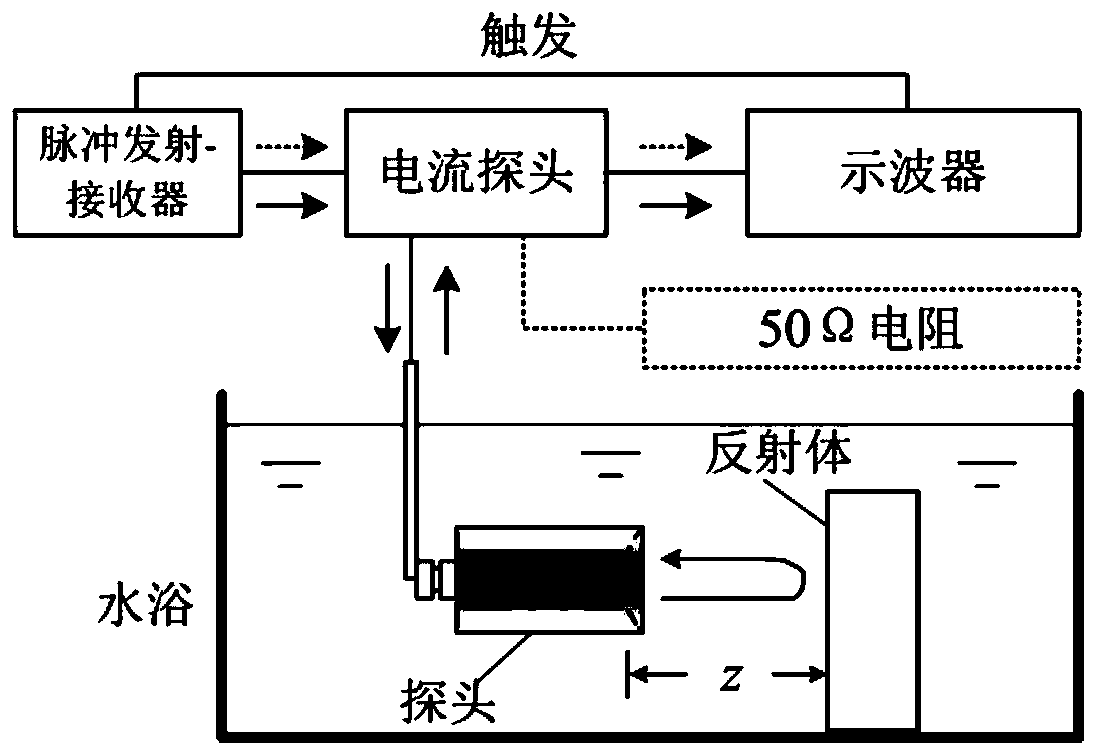

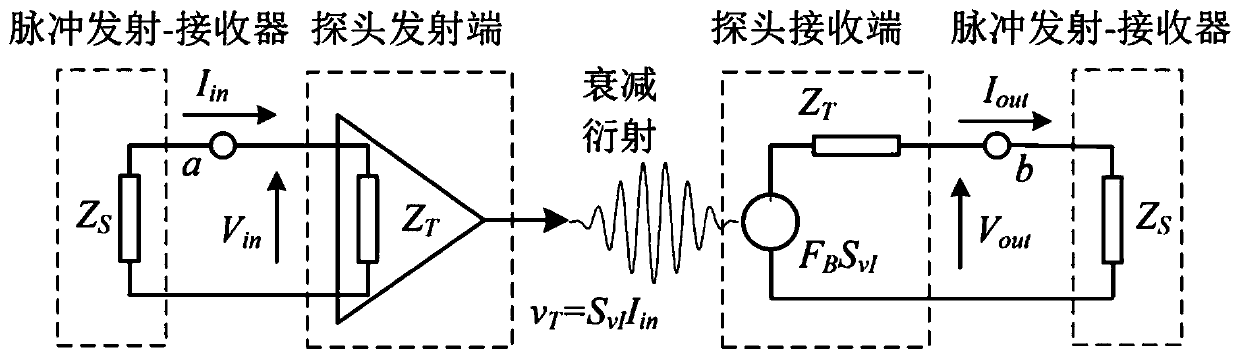

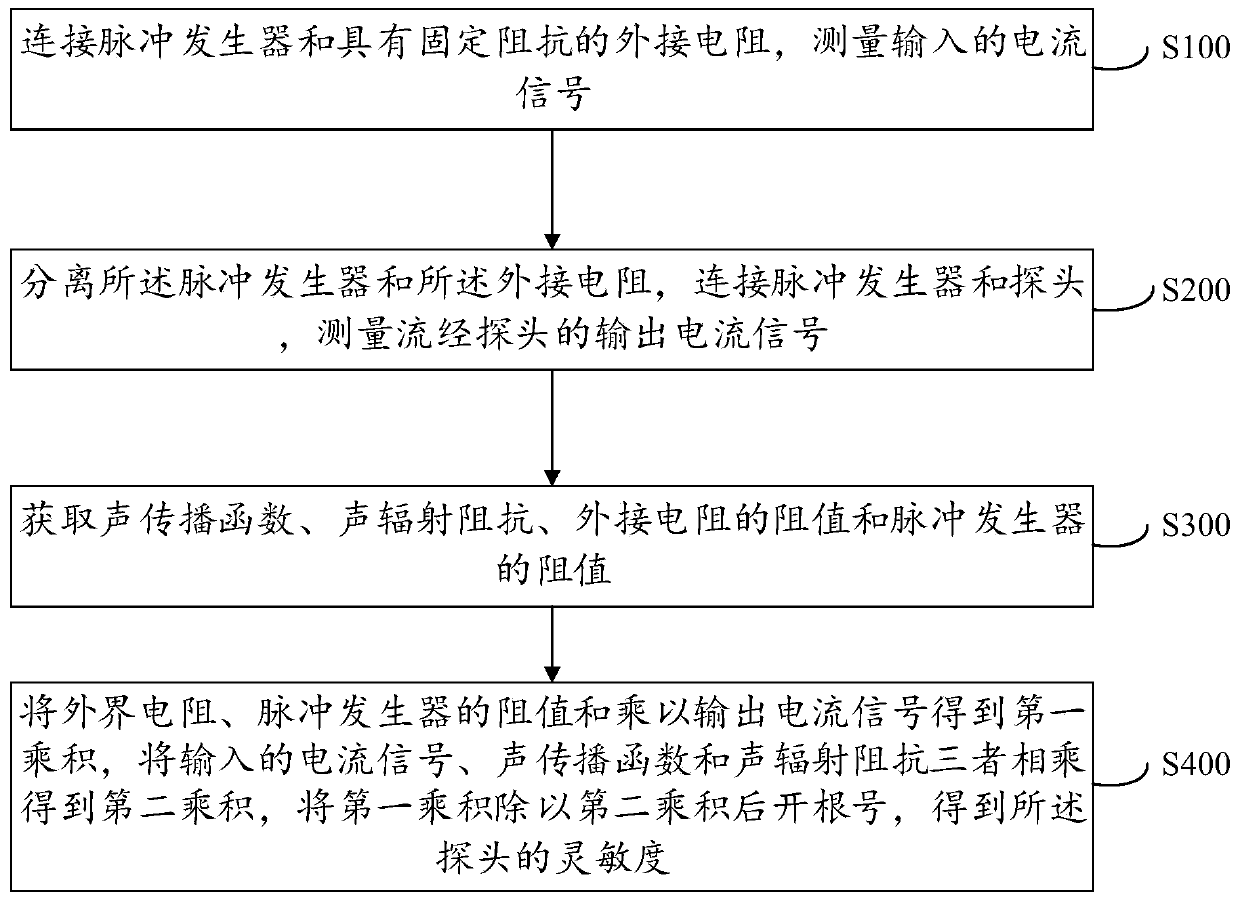

[0058] The experimental setup based on the self-reciprocity verification method is as follows: figure 1 shown. The probe shown in the figure is used for both the transmission and reception of ultrasonic signals. The pulse generator emits ultrasonic electrical pulse signals to drive the ultrasonic probe to generate ultrasonic waves. After the ultrasonic waves propagate in water and are reflected by the test block, they are received by the probe and converted into electrical signals. figure 1 The corresponding two-port circuit network model is as follows figure 2 As shown, the following uses the theory of Lopez-Sanchez and Schmerr to briefly describe the measurement method of the probe sensitivity.

[0059] At the transmitting end of the circuit, when the probe radiates sound waves but before receiving them, we use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com