A step-down DC-DC power supply module remaining service life prediction and health assessment method

A DC-DC, power module technology, applied in electrical digital data processing, biological neural network model, special data processing applications, etc., to achieve obvious social and economic benefits, meet equipment requirements, and important military application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

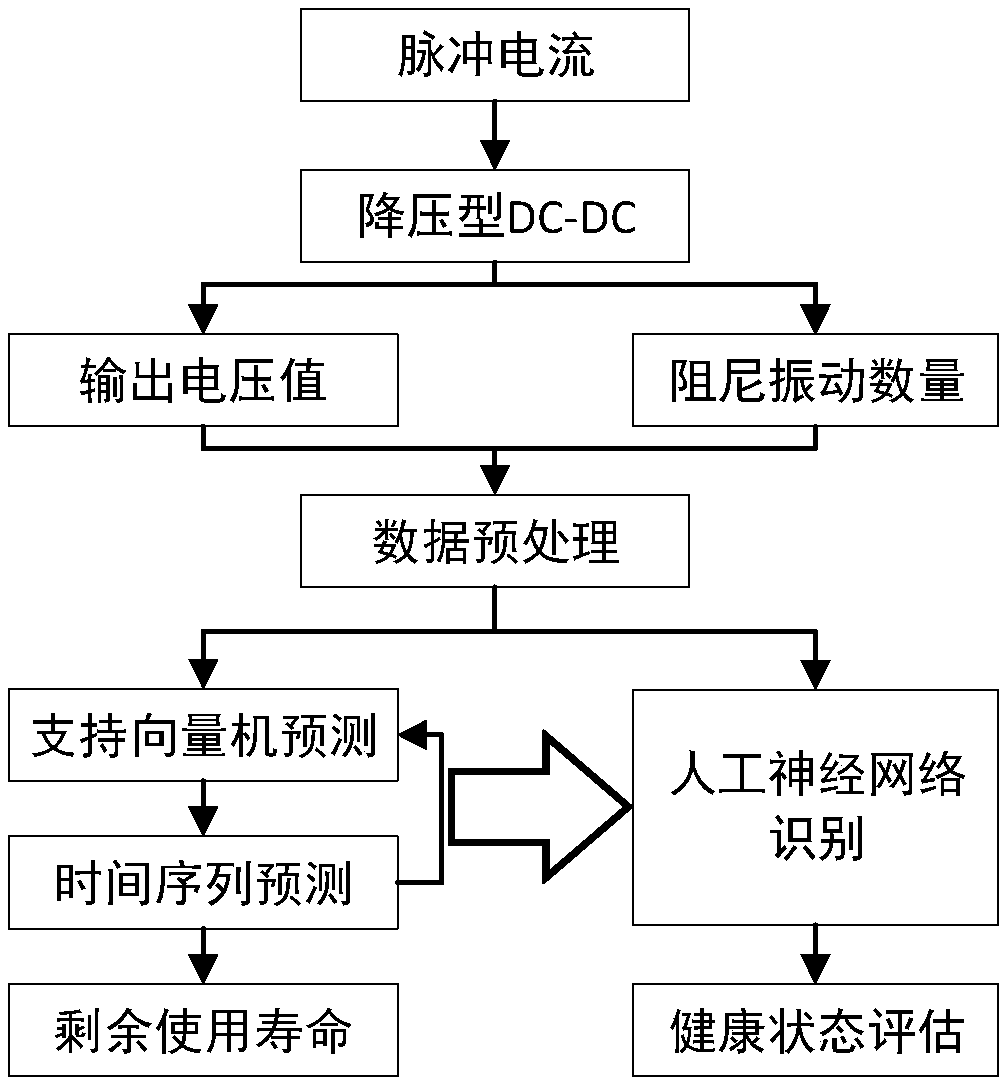

[0070] like figure 1 As shown, a step-down DC-DC power module remaining service life prediction and health assessment method of the present invention, the steps are as follows:

[0071] Step 01: Step-down DC-DC power supply module failure conditions: surge impact generated when powering on and off; overcurrent and short circuit caused by load, and improper use by humans. Too high temperature, too low temperature, thermal cycle and thermal shock cause electrical parameter drift, mechanical deformation, chemical reaction, increase contact resistance, dielectric breakdown and electromigration, etc. Vibration can cause damage to electrical connections, fracture of substrates in microelectronic components, electrical contact or short circuits, fraying of wires, and loose or poor contact of components. Humidity causes corrosion of circuits, electrical shorts, insulation breakdown, and changes in resistance.

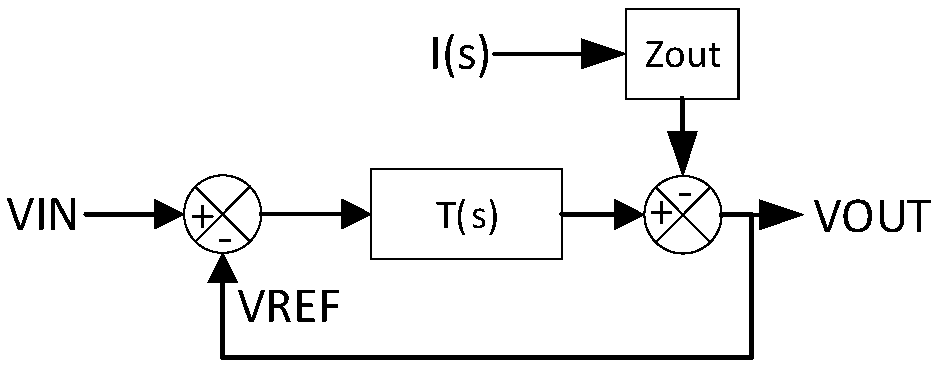

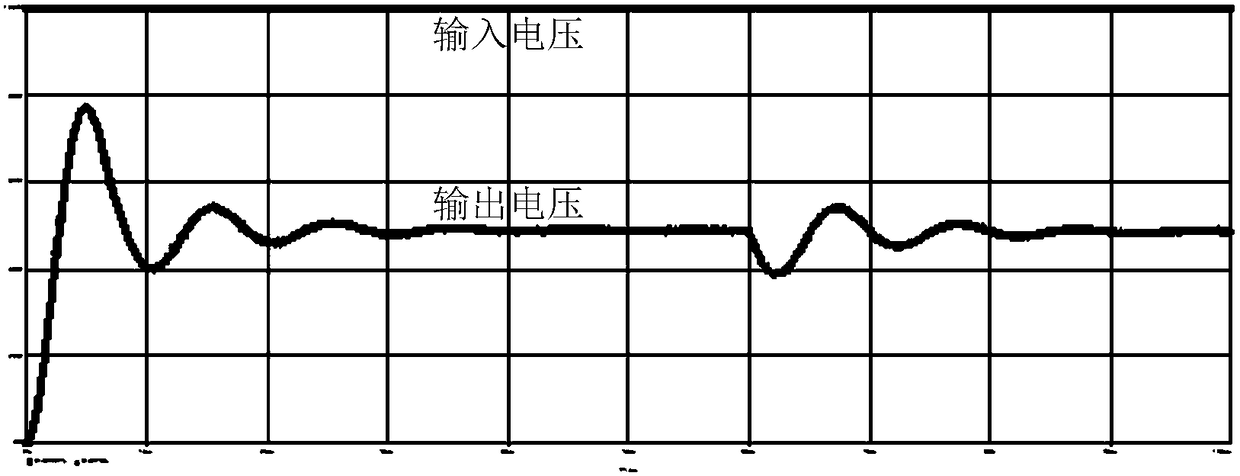

[0072] Step 02: Perform transient response analysis of the step-down DC-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com