Single-sided welded battery module

A battery module, single-sided welding technology, applied in the direction of batteries, battery pack components, circuits, etc., can solve the problems of large battery modules, inconvenient installation, and long time for welding two sides, so as to reduce the volume and reduce the Welding surface, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

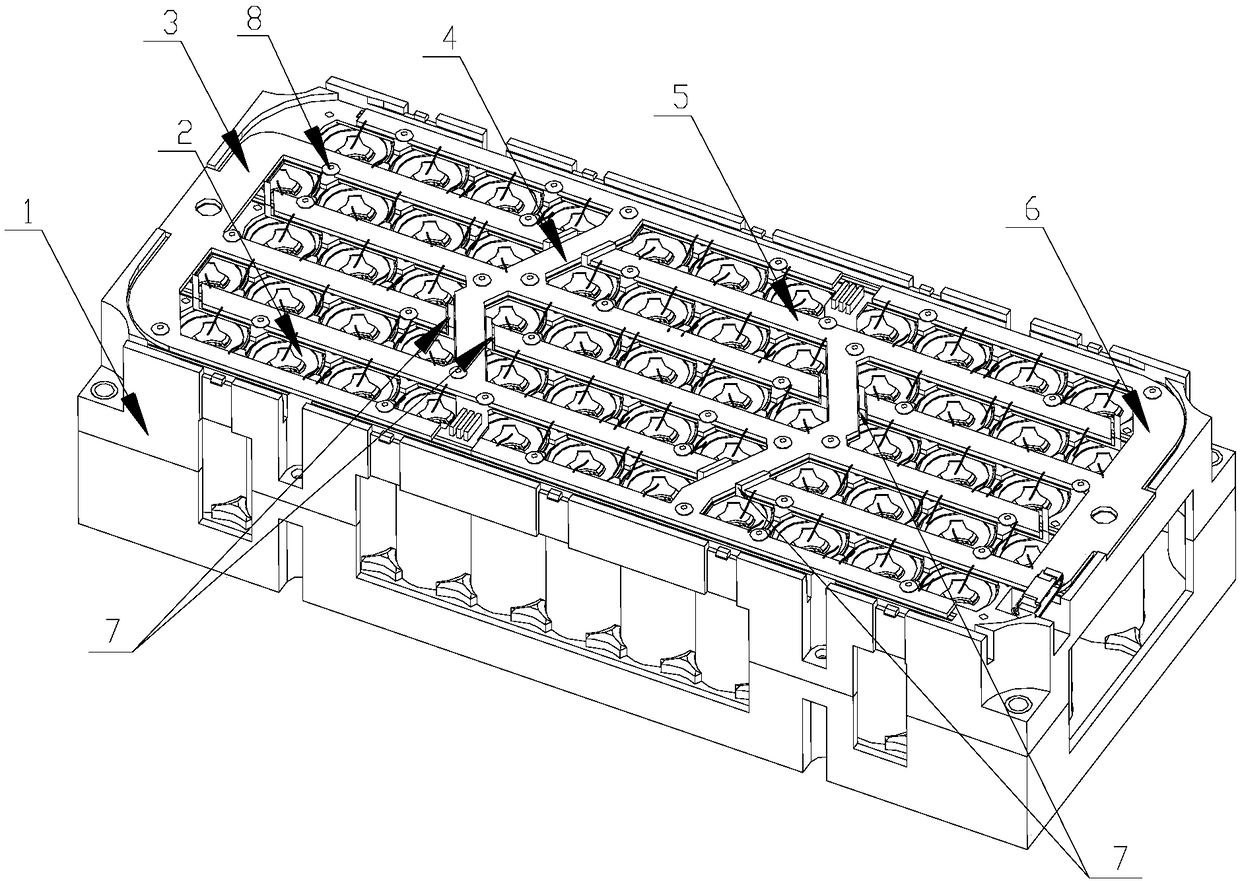

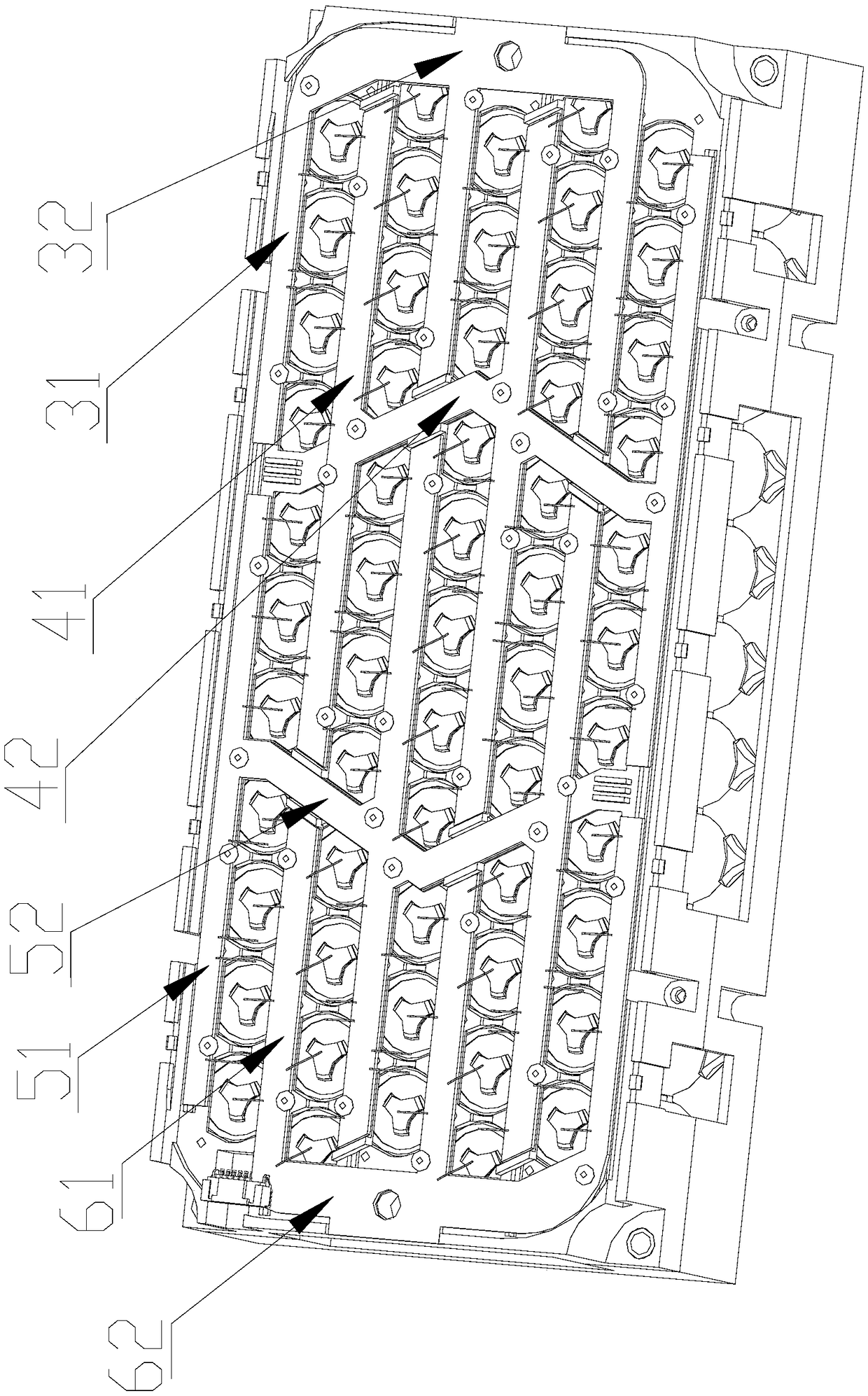

[0026] Such as Figure 1-7 As shown, the battery module includes a battery cell support 1, a plurality of battery cells 2 and a manifold assembly. Each battery cell 2 is placed in the battery cell support 1, and the positive poles of each battery cell 2 face upward. The cell support 1 is fixedly connected, and the manifold assembly is located on the side where the positive pole of the cell 2 is located. The manifold assembly includes a positive manifold 6, a first series manifold 4, a second series manifold 5 and a negative manifold 3 , the positive manifold 6 includes a positive manifold main body 61 and a positive manifold connecting portion 62, the positive manifold main body 61 is composed of a plurality of elongated plates, and each elongated plate is distributed in multiple layers, and the positive manifold connecting portion 62 is connected with the edge of each strip-shaped plate of the main body part 61 of the positive electrode manifold to form a complete positive el...

Embodiment 2

[0032] Cell 2 is divided into two groups. The manifold assembly includes a positive manifold, a negative manifold and a series manifold. One side of the series manifold is adjacent to the negative manifold, and the other side of the series manifold is adjacent to the positive manifold. , of the two groups of cells, one group of cell positive poles is welded to the main part of the positive bus plate by welding wire, one side of the cell shell of this group and the main body of the series bus plate is welded by welding wire, and the shell of the other group of cells is The positive electrode of the other group of cells is welded to the other side of the main body of the series manifold by welding wire.

Embodiment 3

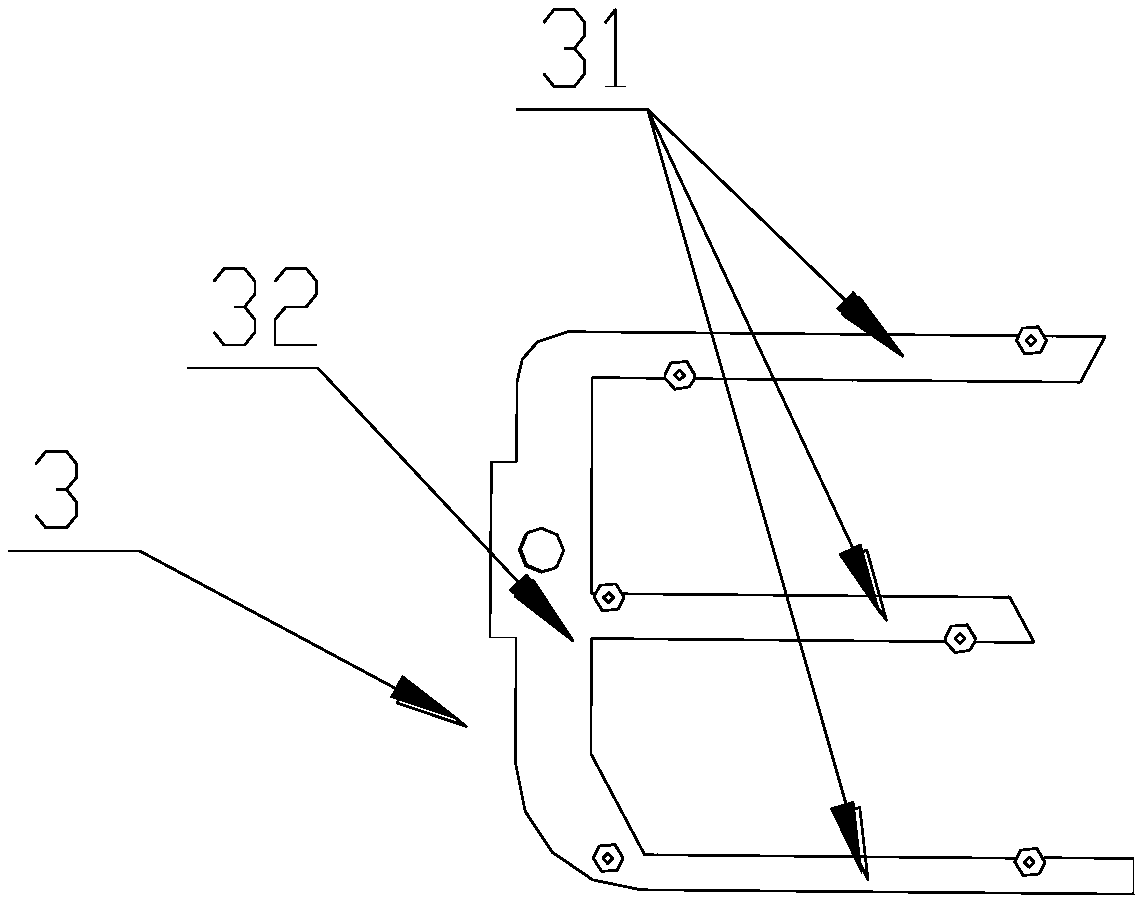

[0034] Such as Figure 8 As shown, in the battery module, only the cells 2 need to be connected in parallel, and the cells do not need to be connected in series, so only the positive manifold 3 and the negative manifold 4 are included, and the positive manifold 6 includes the main part of the positive manifold 61 and The positive manifold connecting part 62 and the positive manifold main body 61 are composed of a plurality of strip-shaped plates, each of which is distributed in multiple layers, the positive manifold connecting part 62 and each strip of the positive manifold main part 61 The edges are connected to form a complete positive manifold. Negative electrode manifold 3 comprises negative electrode manifold body part 31 and negative electrode manifold connecting part 32, and negative electrode manifold body part 31 is made up of a plurality of elongated plates, and each elongated plate is multilayer distribution, and negative electrode manifold connecting part 32 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com