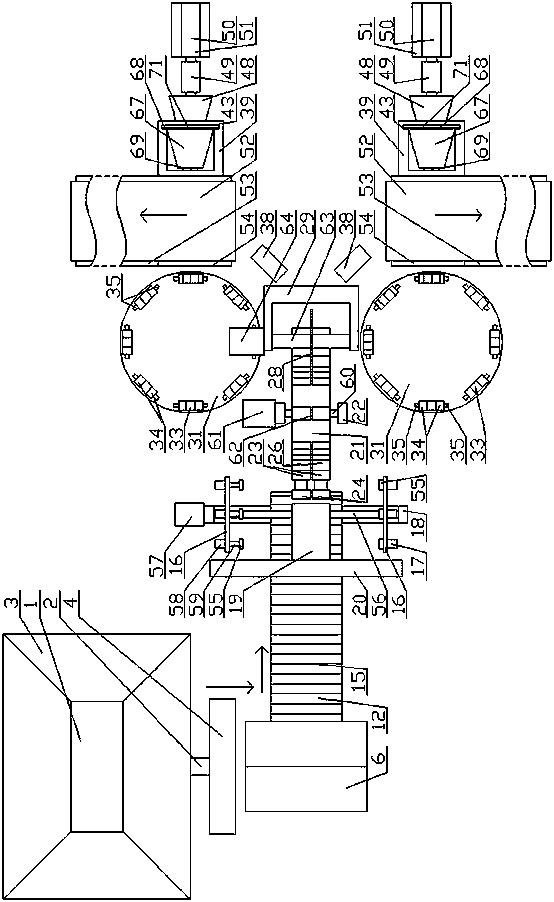

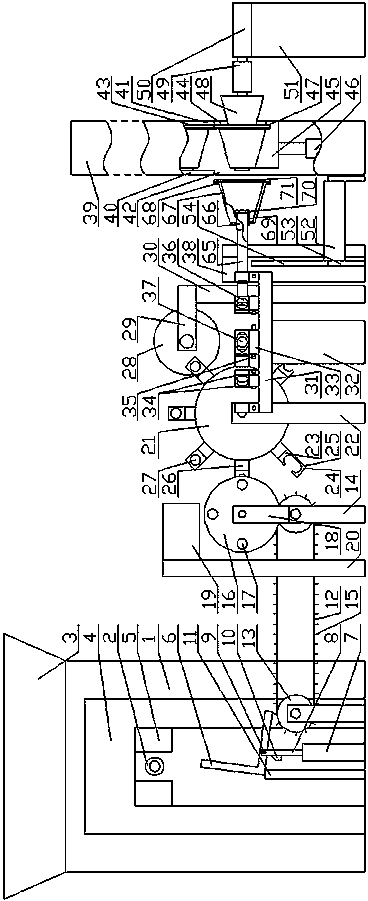

Full-automatic production line for moxibustion strips

A technology of moxibustion strips and production lines, applied in passive exercise equipment, heating/cooling reflex point equipment, and devices that make medicines into special physical or ingestible forms, can solve low production efficiency, increase production costs, Moxibustion stick damage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

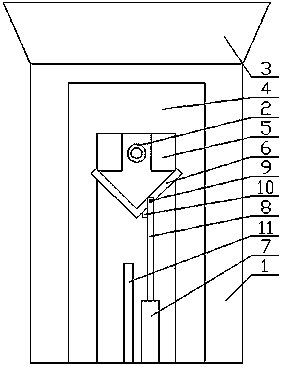

[0050] combine Figure 1~Figure 3 It can be seen that the present invention includes an extruder 1, a section cutting device, a wrapping device 19, a cutting device, a base installation device and a discharge conveying device in sequence, and the section cutting device is arranged at the end of the extrusion pipe 2 of the extruder 1 , The section cutting device is connected with the rotary chuck A16 through the epicyclic transfer device, the rotary chuck A16 is connected with the rotary chuck B21 after passing through the wrapping device 19, and the rotary chuck B21 is connected with the rotary chuck after passing through the cutting device C31 is connected, and the rotating chuck C31 passes through the base mounting device and the discharging transmission device in turn.

[0051] The edge of the feed port of the extruder 1 is provided with a flaring guide retaining ring 3 .

[0052] Described cutting device comprises " door " font support 4, and described extruding pipe 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com