Protective dismantling method for large spherical tank

A protective and spherical tank technology, applied in the field of protective dismantling of large spherical tanks, can solve problems such as waste and impractical long-distance relocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

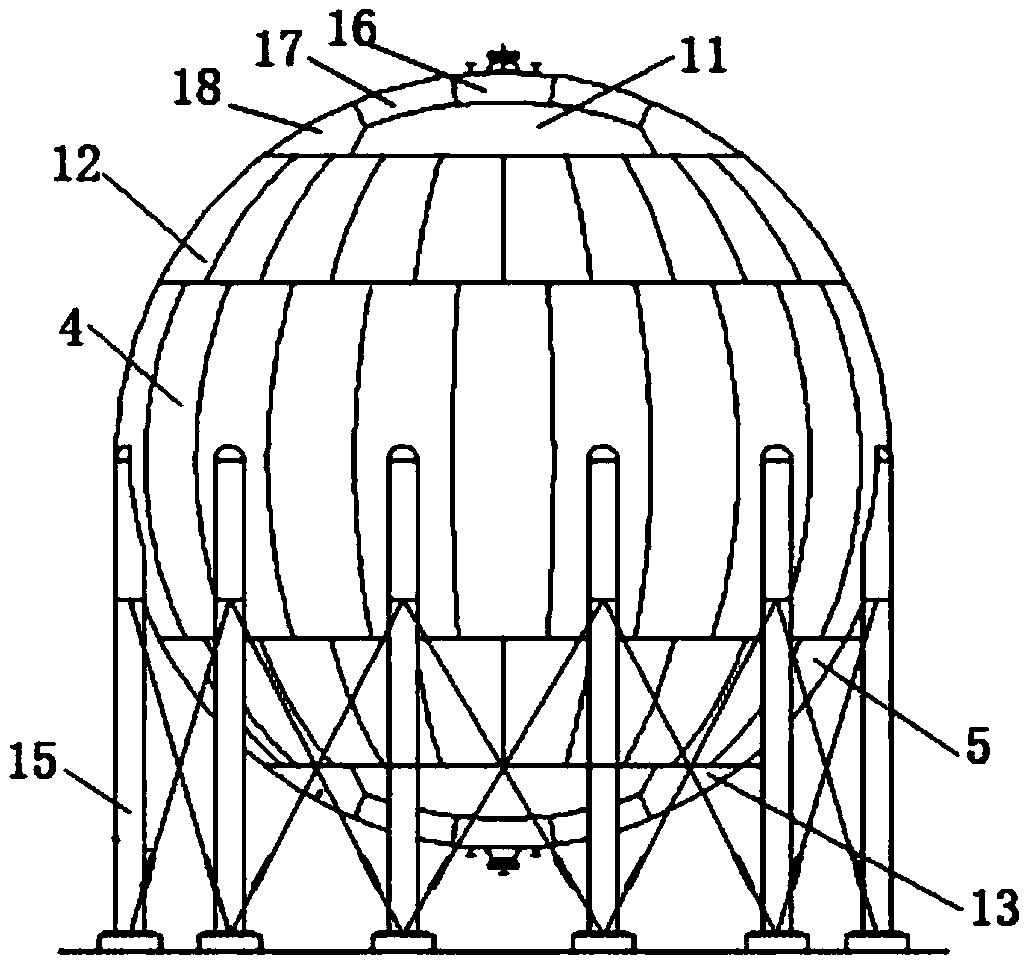

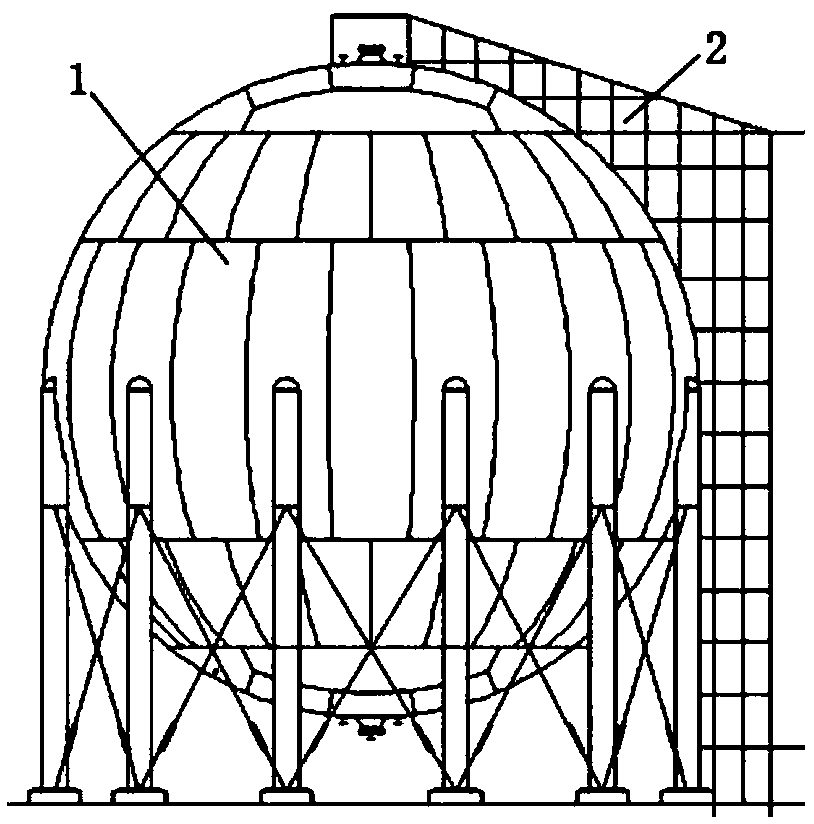

[0035] The embodiments of the present invention will now be described in conjunction with the accompanying drawings, and the present invention is not limited to the following embodiments.

[0036] 1. Spherical tanks to be dismantled 1 Do necessary exhaust and liquid discharge and gas detection work, especially for spherical tanks with flammable and explosive media such as liquefied hydrocarbons, cleaning work should be done before dismantling to ensure safety.

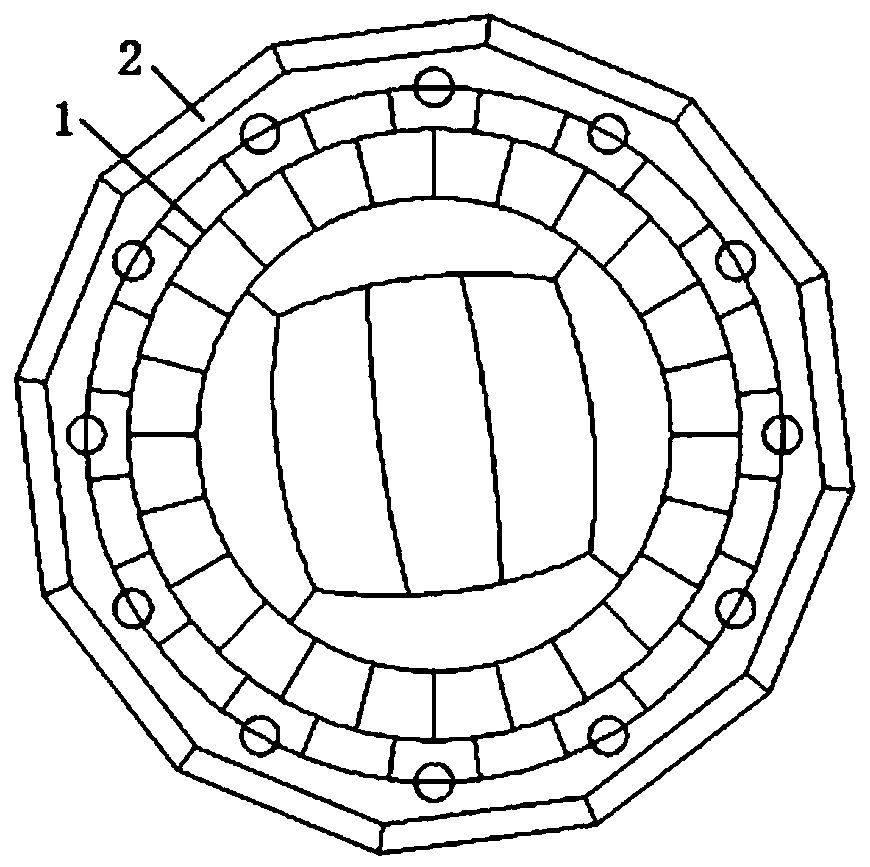

[0037] 2. According to the size of the spherical tank, set up scaffolding 2 on the periphery of the spherical tank. The scaffolding has two layers, with a distance of 1 meter and a height of 1.8 meters to 2 meters. An operation platform is laid on the scaffolding at and above the equator. Such as figure 2 , image 3 shown.

[0038] 3. After the scaffolding is erected, weld square caps 3 along both sides of the weld seam of the spherical tank. According to the weld layout of the spherical tank to be dismantled, draw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com