Steel pipe welding protection gas tool

A technology for shielding gas and steel pipes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large amount of shielding gas, difficult welding position and difficulty, difficulty in improving welding efficiency, etc. The effect of preparation time before welding, reducing the use of shielding gas, and reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

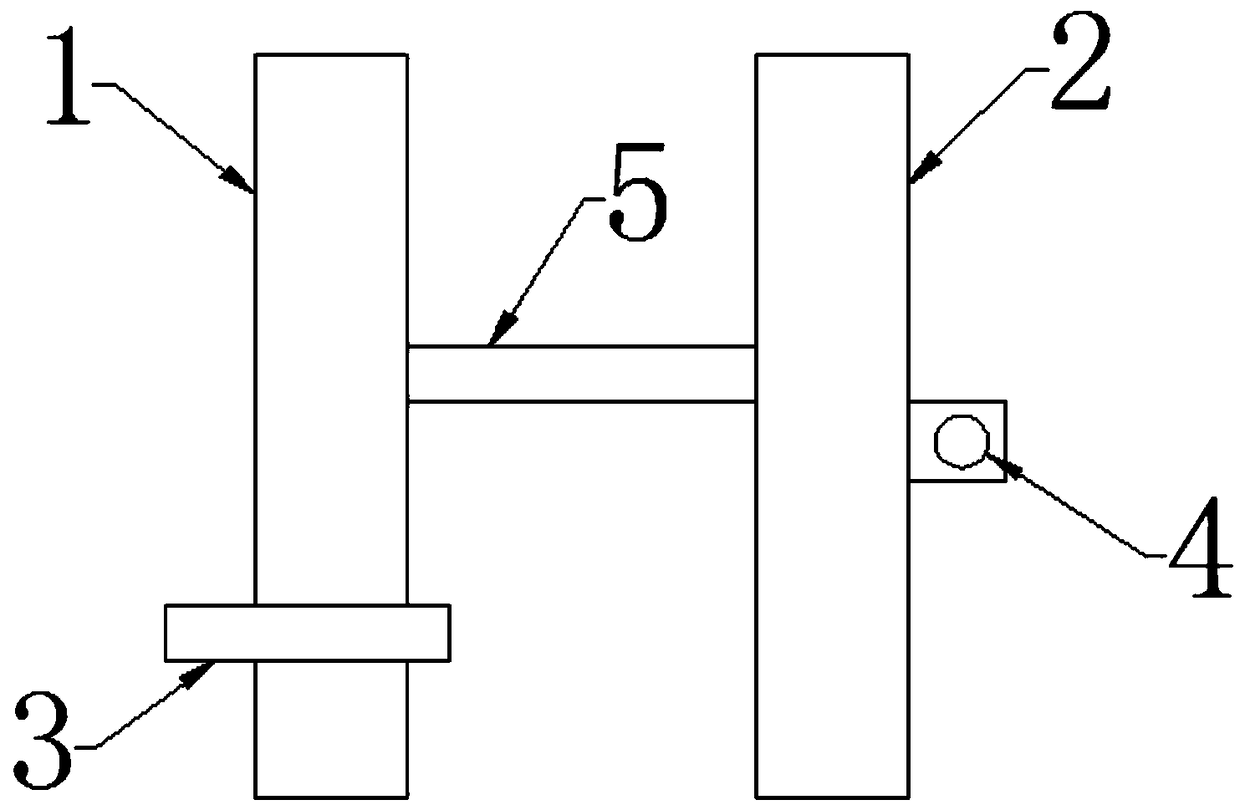

[0019] Such as figure 1 As shown, a steel pipe argon arc welding inflatable tooling of the present invention includes a left seal 1 and a right seal 2, the left seal and the right seal are closely matched with the inner wall of the steel pipe, and the left seal is provided with a through hole Argon inflating tube 3 is arranged in the through hole, and the opposite side of the left seal and / or the right seal is provided with a hanging ring 4 for fixing the traction part, and the hanging ring is connected with the traction outside the steel pipe. file connection. The opposite surfaces of the left seal and the right seal are connected by a limit rod 5, so that the distance between the left seal and the right seal is 10-20cm.

[0020] The limit rod can be a straight rod, and two blind holes are arranged on the relative positions of the left seal and the right seal. The distance between them should be avoided if the distance is too small, there is not enough argon to protect the ...

Embodiment 2

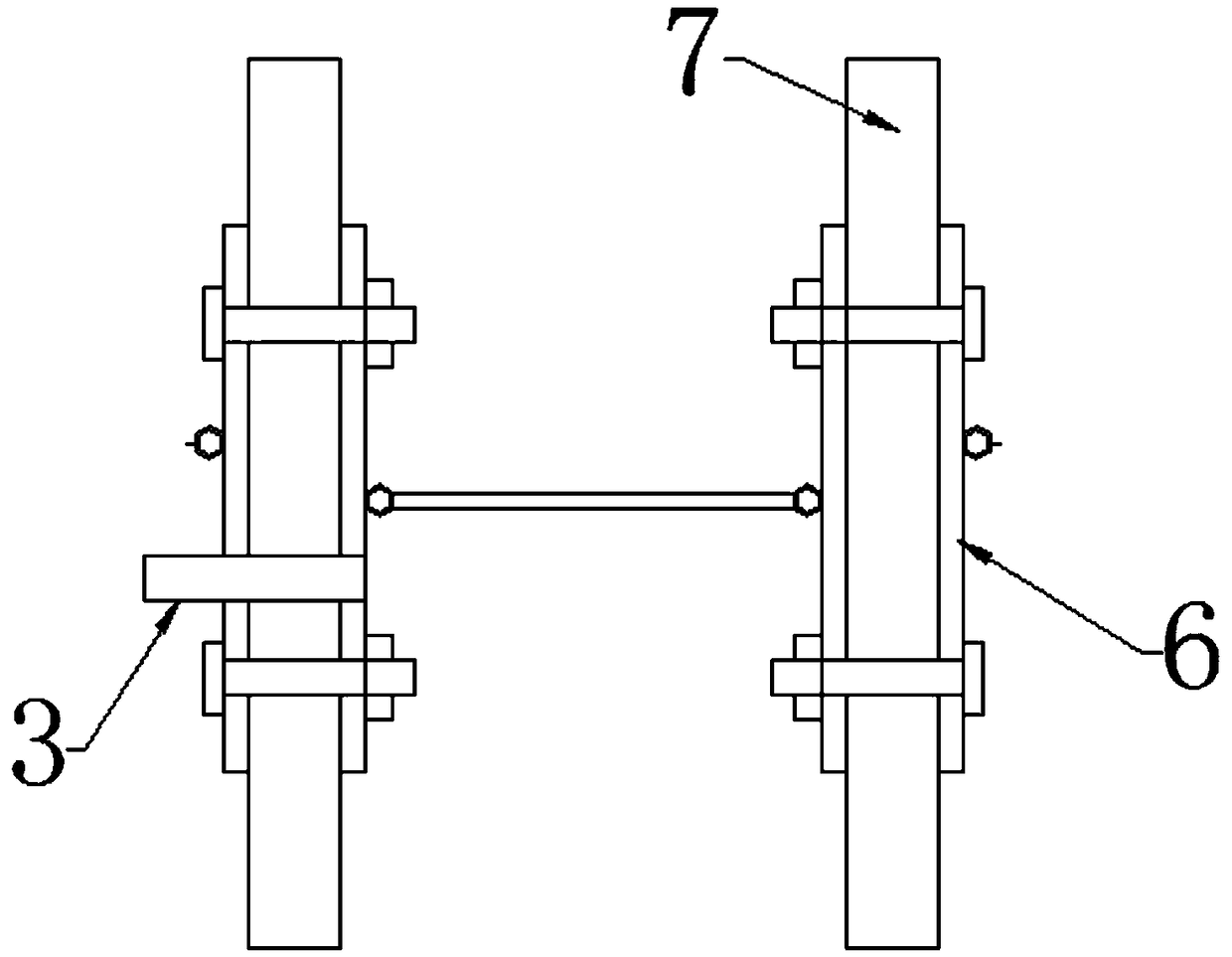

[0022] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that the seal is composed of a splint 6 and a seal ring made of flexible material, the outer diameter of the splint 6 is smaller than the inner diameter of the steel pipe, and a seal ring is sandwiched between the splints. The inflation tube runs through the splint. The sealing ring is a circular sheet sponge 7 with a thickness of 5-10 cm. The splint is fixed with the sponge sealing ring through the cooperation of bolts and nuts.

Embodiment 3

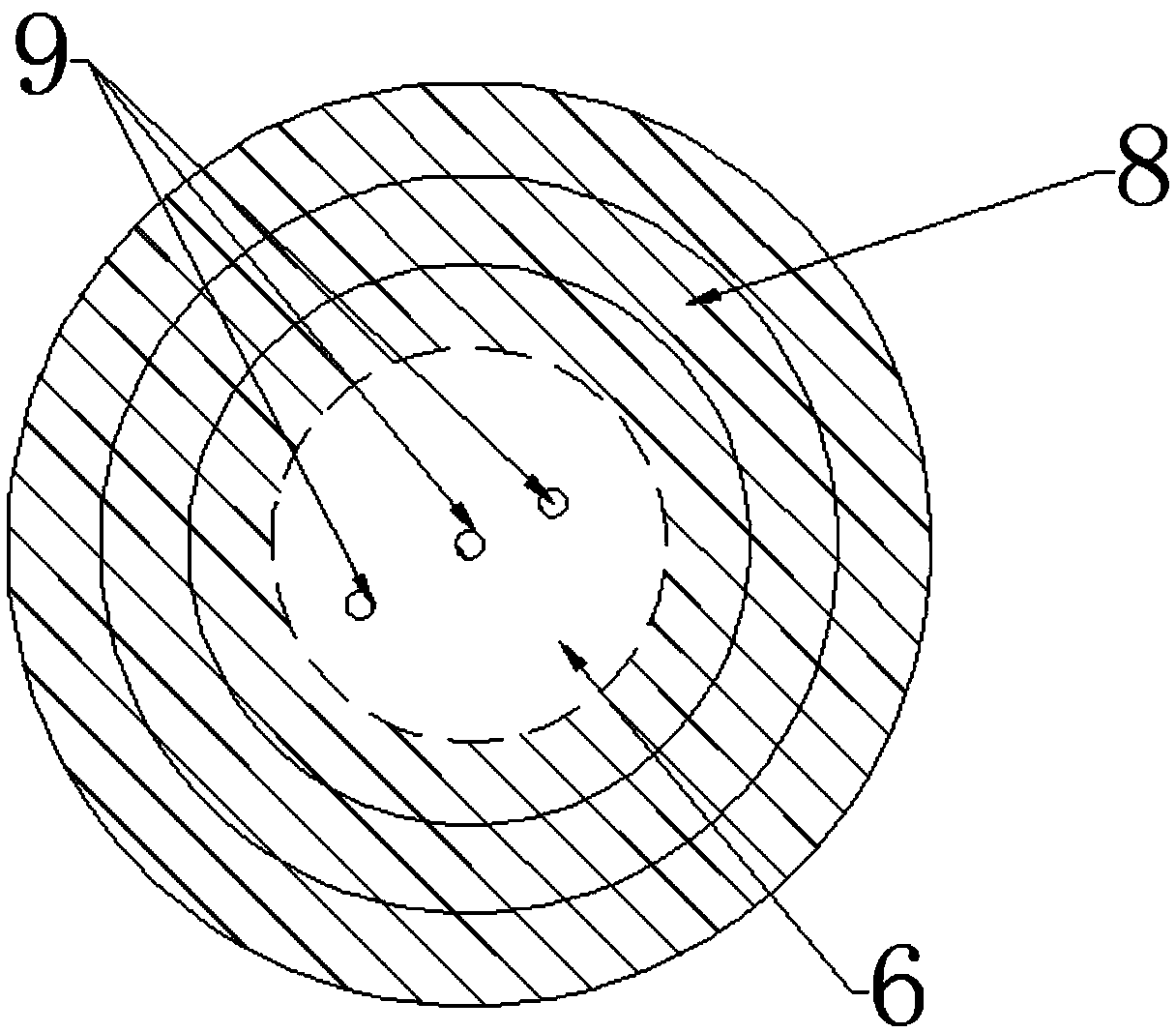

[0024] Such as image 3 As shown, the difference between embodiment 3 and embodiment 2 is that the sealing ring is an air bag 8 sandwiched in the splint 6, and the inflation port 9 of the air bag is arranged on the plane of the splint. The airbag is a three-layer annular airbag, wherein each layer of annular airbag has a separate inflation port.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com