Roughening knife and method for manufacturing orange-peel-shaped rubber roller

A technology of textured knives and rubber rollers, applied in the field of rubber roller turning processing, can solve the problems of orange peel-shaped rubber rollers and other problems, and achieve the effects of improving grinding force, uniform force, and eliminating the decrease of blade hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

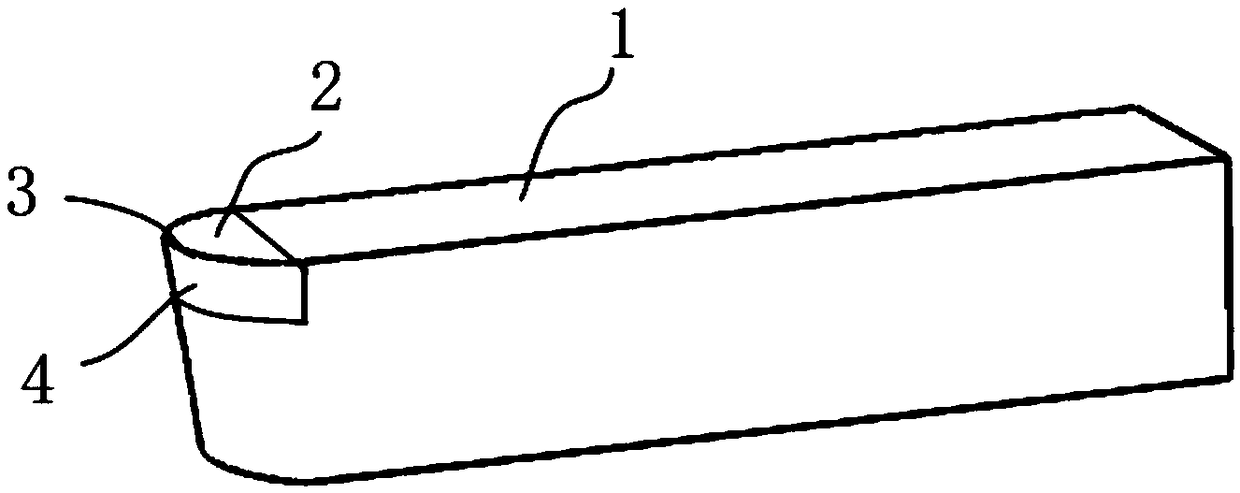

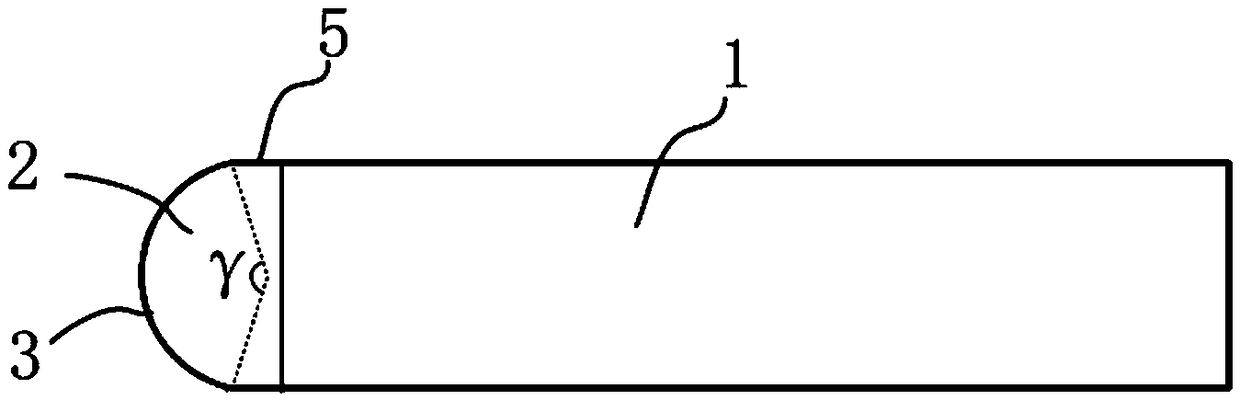

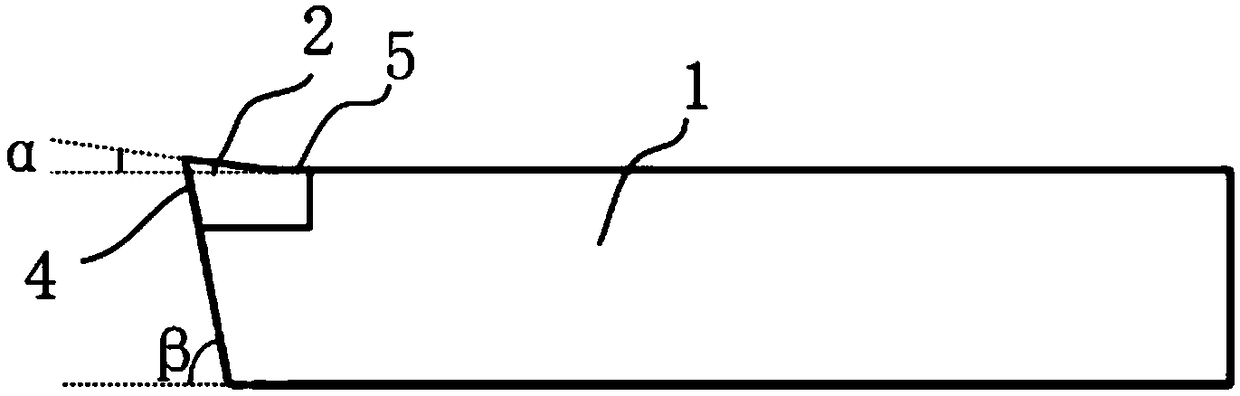

[0046] Such as figure 1 , figure 2 and image 3As shown, the texturizing knife of this embodiment is mainly composed of the handle 1 and the cutting part. The handle 1 and the cutting part are integrated, which eliminates the defects such as the decrease in hardness of the blade and the generation of cracks caused by welding. The outside of the handle 1 is in the shape of a cuboid. The cutting part is arranged at one end of the handle 1 and is located on the upper side of the end. In the cutting part, the planar rake face 2 intersects with the main flank face 4 which is an arc surface. The arc-shaped main cutting toughness 3 is formed, and the angle range of the arc angle γ of the main cutting toughness 3 is 90°~180°. The setting of the arc angle γ makes the main cutting toughness 3 when texturing the rubber roller, Grinding with the rubber roller during the operation of the lathe without damaging the surface of the rubber roller, changing the original turning purpose of th...

Embodiment 2

[0062] In this embodiment, the materials of the textured knife and the orange-peel rubber roller used are the same as in Example 1, and four orange-peel rubber rollers with a specification of Φ250×1500mm are also produced, the difference is that:

[0063] In this embodiment, in the orange-peel-shaped rubber roller production step, in the rubber roller wear debris: take the diameter of the rubber roller as a benchmark, control the lathe speed to 330 rpm and the cutting speed to 1.1mm / rev, and the amount of feed at this time is the same as that of the rubber roller The density of the orange peel is inversely proportional, and the cutting amount is controlled to 0.22mm to produce an orange peel rubber roller with uniform density.

[0064] The relevant test record data of 4 pieces of orange peel rubber rollers are as follows in Table 3:

[0065] table 3

[0066]

[0067] As can be seen from the above table 3, adopting the material of the texturing knife and the orange peel rub...

Embodiment 3

[0069] Such as figure 2 , image 3 , Figure 4 As shown, on the basis of Embodiment 1, the texturizing knife of this embodiment also includes a secondary cutting toughness 5 and a secondary flank 6, wherein the secondary flank 6 is a smooth plane connected to the Between the two ends of the main flank 4 and the handle 1; the intersection of the rake face 2 and the auxiliary flank forms a secondary cutting toughness 5, which is straight and connected to the two ends of the main cutting toughness 3 and the Between the handle 1, after the main cutting toughness 3 of the texturing knife is worn, the main cutting toughness 3 can be reground along the secondary cutting toughness 5, so that the service life of the texturing knife can be extended.

[0070] Next, use the above-mentioned texturing knife to make four pieces of orange-peel-shaped rubber rollers with a specification of Φ840×1600mm. The specific production process is as follows:

[0071] (1) Preparation of sizing materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com