Device and method for preparing krypton-xenon concentrate in liquid oxygen

A technology of concentrate and liquid oxygen, applied in separation methods, chemical instruments and methods, inert gas compounds, etc., can solve the problems of complex process, weak safety, high cost, and achieve simple process, high safety, and working process. Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

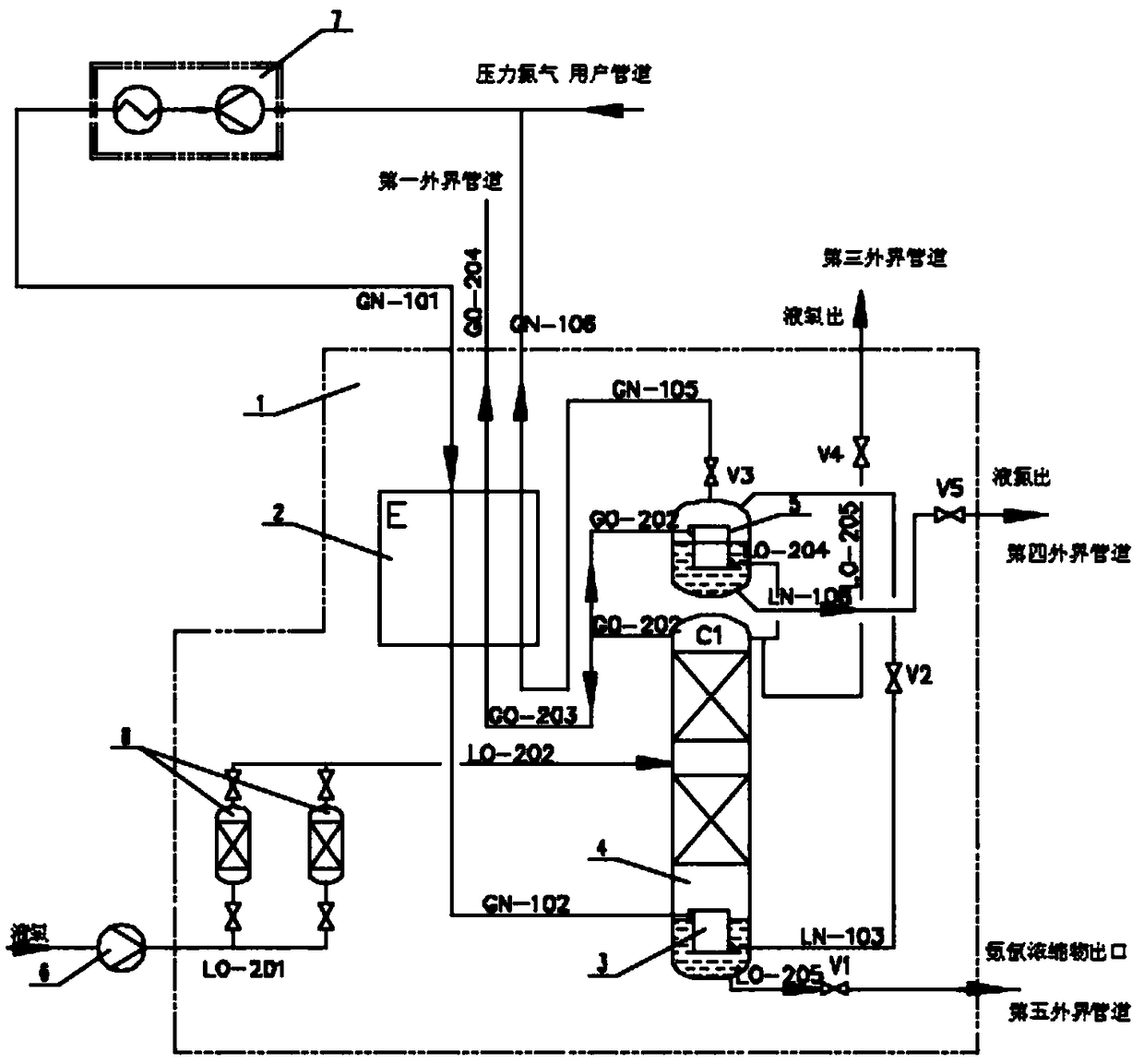

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] as attached figure 1 As shown, the liquid oxygen produced by air separation (1200Nm 3 / h, slightly positive pressure, the ingredients contained in this embodiment are: O2: 99.7%; Kr: ~109ppm; Xe: 17ppm; Methane: ~33ppm; other components: argon), through the liquid oxygen pump 6 After being pressurized to 0.3MPaA, it is sent to the cold box through the pipeline LO-201, firstly enters the low-temperature adsorber 8 to remove trace nitrous oxide and carbon dioxide, and then is sent to the middle of the rectification tower to participate in rectification and concentration. The operating pressure of the rectification tower 4 involved in rectification and concentration is 0.18MPaA, and the boiling point temperature of the mixture (air separation liquid oxygen: mainly liquid oxygen) under this pressure is -177.3°C. The air-separated liquid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap