Warp knitting machine for producing woolen lint chamois simulated textile products

A technology of woolen imitation and warp knitting machines, applied in the field of warp knitting machines, can solve the problems of rising cost of suede plush, the inability of light and thin autumn and winter garments, and the inability to form industrial advantages, etc., so as to achieve a wide range of product adaptation and practicality Strong, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

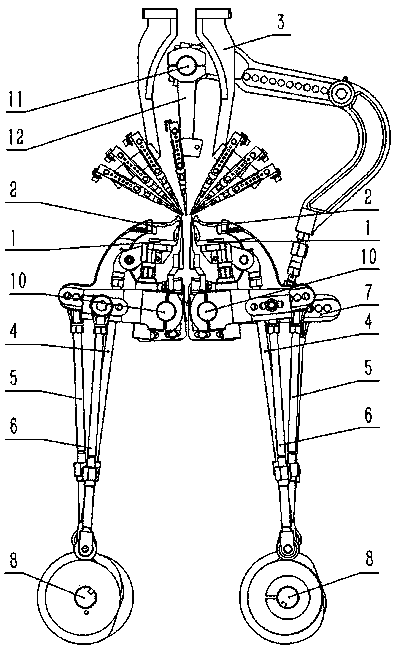

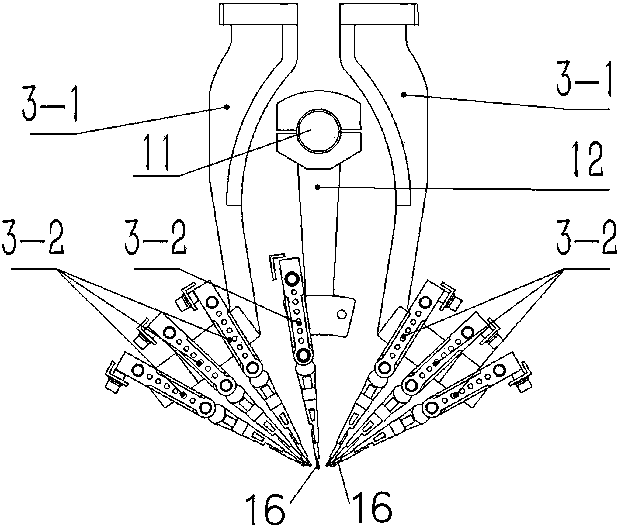

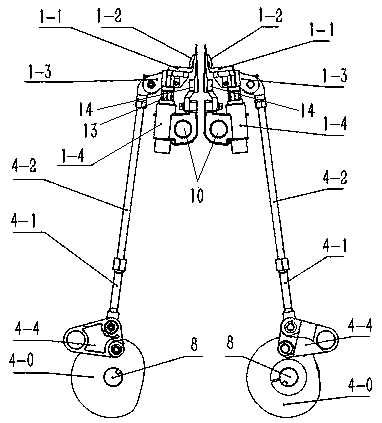

[0035] See attached figure 1 To attach Figure 14 , the present invention proposes a kind of warp knitting machine that is used to produce wool plush imitation suede fabric, comprises warp knitting machine frame, is provided with loop forming device on the warp knitting machine frame, is arranged on the warp knitting machine frame The ground comb device 3, the loop forming device includes two symmetrical needle bed assemblies 1 and two symmetrical sinker bed assemblies 2 arranged on the warp knitting machine frame, and two left and right needle bed assemblies are movably connected on the warp knitting machine frame. Symmetrical pendulum shaft 10, two needle bed assemblies 1 and sinker assembly 2 are respectively movably connected on the two pendulum shafts 10, and also includes tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com