A device for printing and dyeing cloth

A cloth and equipment technology, applied in the field of equipment for printing and dyeing cloth, can solve problems such as affecting the quality of the cloth, uneven dyeing of the cloth, affecting the color of the cloth, etc., and achieve the effect of consistent color, dye saving and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

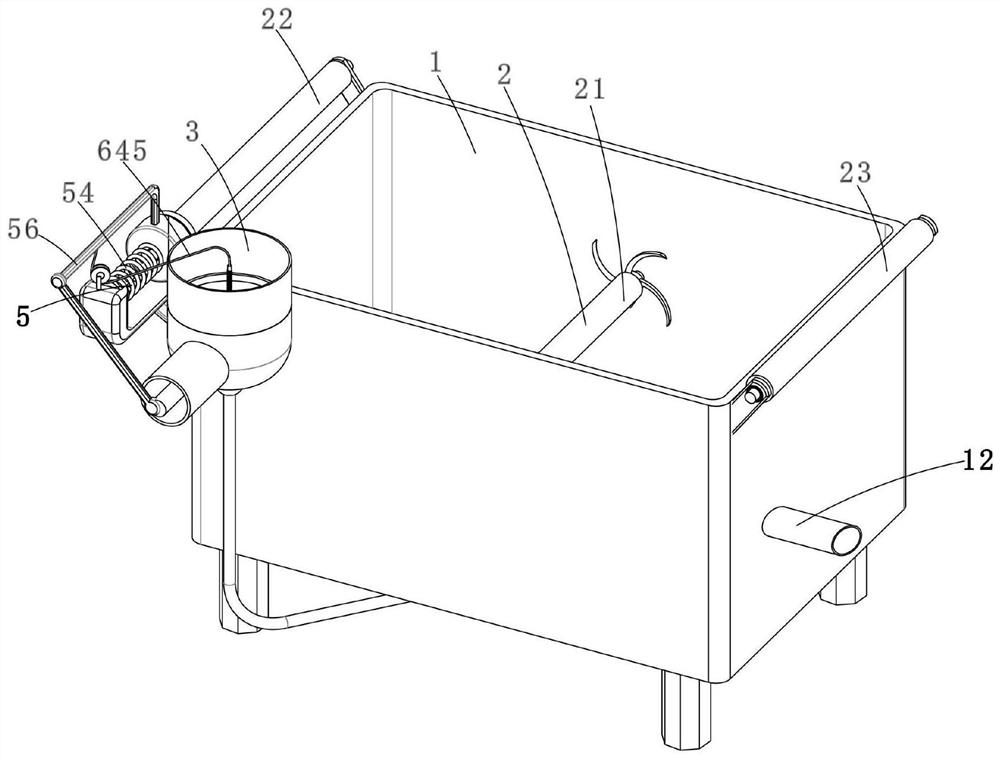

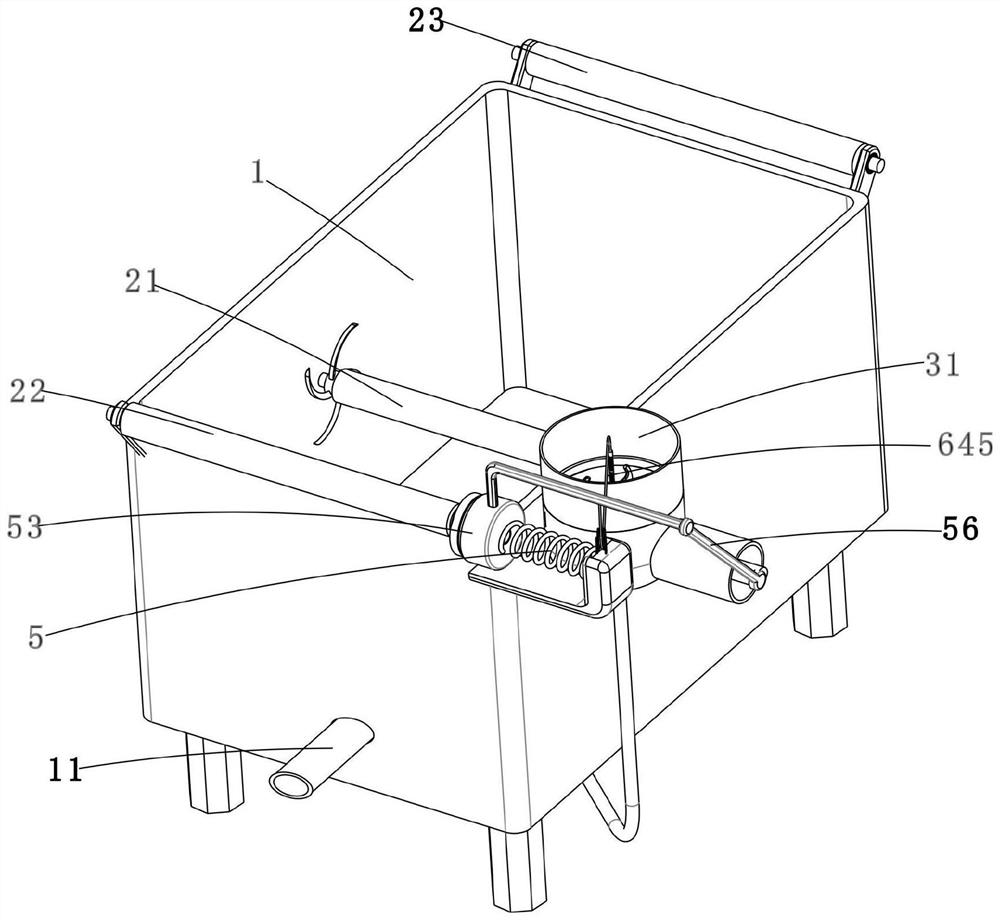

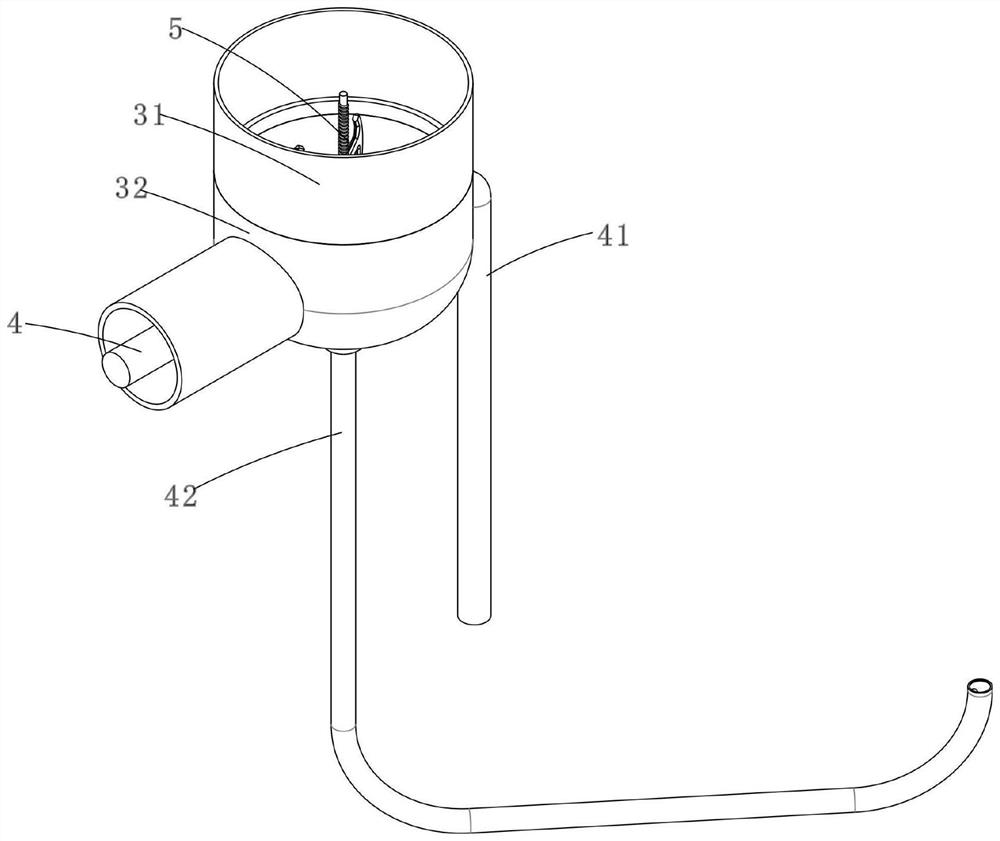

[0043] Such as Figure 1-15 As shown, a kind of equipment for printing and dyeing cloth, including dyeing pool 1, cloth passing roller 2, liquid supply pipe 11, liquid drainage pipe 12 and feeding device 3, wherein said dyeing pool 1 is a metal pool, and the dyeing liquid is directly stored In the middle of the dyeing pool 1, the liquid supply pipe 11 is a metal pipe connected with a ball valve, the liquid supply pipe 11 communicates with the dyeing pool 1, and the liquid discharge pipe 12 is also a metal pipe connected with a ball valve. Metal pipe, the liquid discharge pipe 12 is in communication with the dyeing pool 1, so the dye solution in the dyeing pool 1 enters into the liquid supply pipe 11, and then is discharged from the liquid discharge pipe 12; the cloth passing roller 2 includes a first Roller body 21, the second roller body 22 and the third roller body 23, the first roller body 21 is located inside the dyeing pool 1, and the first roller body 21 is movably conne...

Embodiment 2

[0053] Such as Figure 16-19As shown, the difference between this embodiment and Embodiment 1 is that the present invention discloses a method for extruding excess dye liquor on the cloth after exhaustion and for pre-drying the cloth after exhaustion, and then drying the cloth; Specifically: the liquid squeezing device 7 is composed of two metal rollers, the liquid squeezing device 7 is arranged above the dyeing pool 1, after the cloth is squeezed, the dye liquid squeezed out from the cloth will flow into the dyeing pool 1; the drying device 8 includes an oven 81, a hot air part 82 and a roller body part 83, the oven 81 is a metal box, and the oven 81 has a plurality of ventilation openings 811, and the hot air part 82 is located on the In the oven 81, the hot air part 82 is a pipeline connected with a fan, and a heating wire is arranged in the pipeline; the roller body part 83 is arranged in the oven 81.

[0054] Further, the roller body part 83 includes a heating roller 831...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com