In-situ nondestructive concrete carbonization depth measurement device and method thereof

A carbonization depth and measuring device technology, which is applied to measuring devices, suspension and porous material analysis, instruments, etc., can solve the problems of insufficient representativeness of detection results and large errors of manual observation, so as to facilitate subsequent calculation and processing and avoid cleaning work , easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

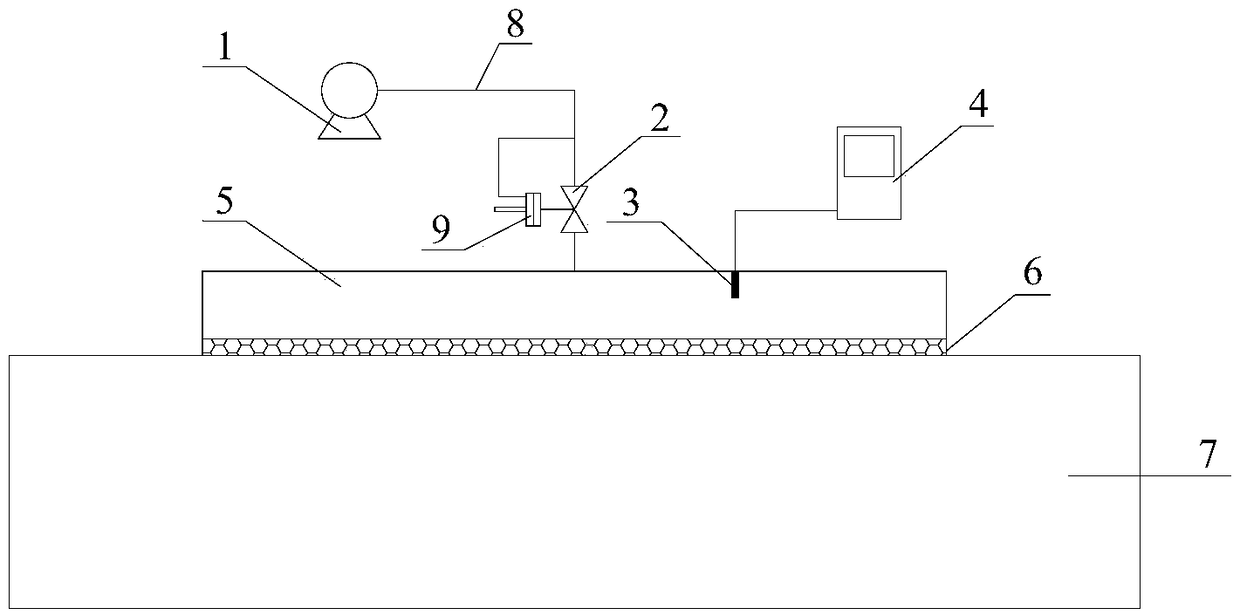

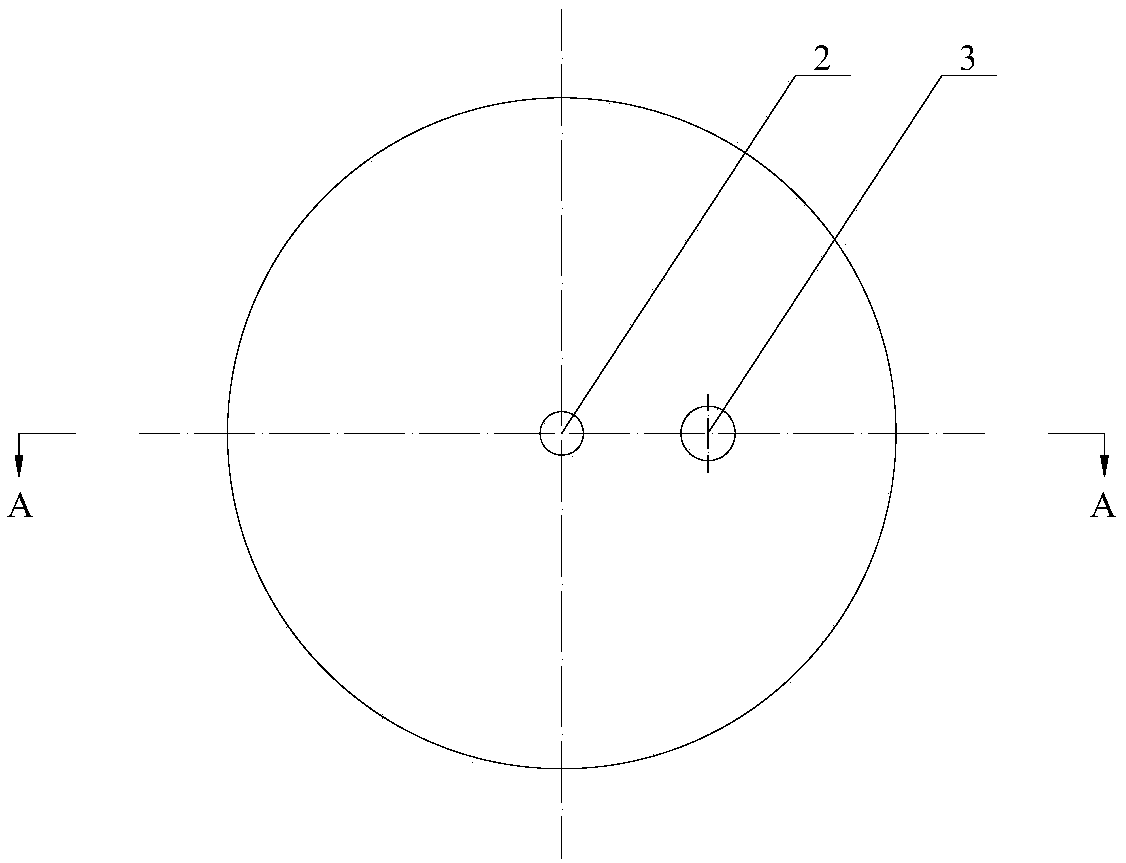

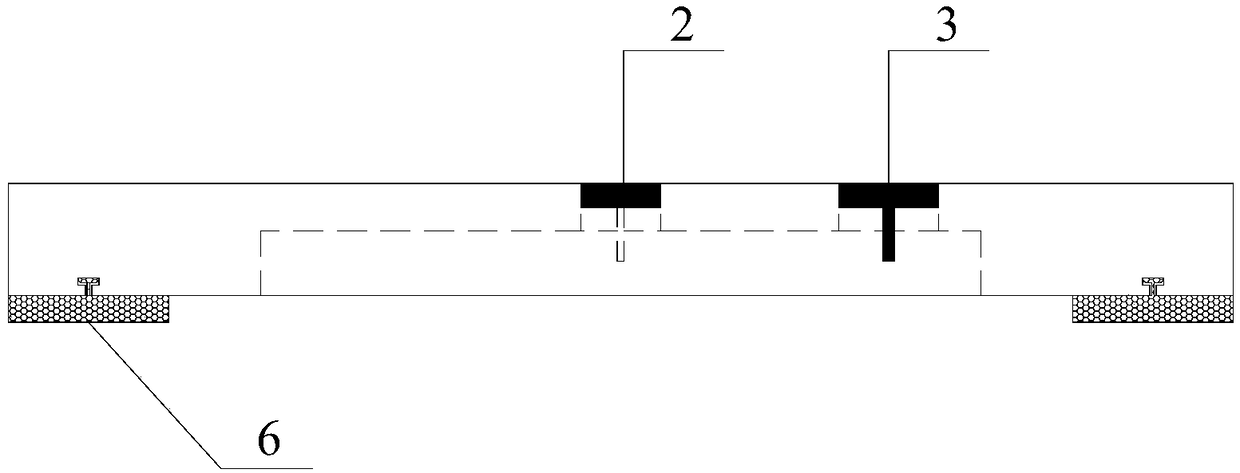

[0047] Attached below Figure 1-3 , the present invention will be further described.

[0048] An in-situ non-destructive measurement device for the carbonation depth of concrete, comprising an air compressor 1, an air valve 2, a pressure sensor 3, a data acquisition system 4, a measuring head 5, a rubber bottom ring 6 and a pressure regulating valve 9, and a The rubber bottom ring 6, the probe 5 includes the probe cavity and the probe air inlet, one end of the pressure sensor 3 is connected to the probe cavity, the other end of the pressure sensor 3 is connected to the data acquisition system 4, and the probe air inlet passes through the air pipe 8 It is connected with the air valve 2, the air valve 2 is connected with the air compressor 1 through the air pipe 8, the air compressor 1 is connected with the pressure regulating valve 9 through the air pipe 8, and the pressure regulating valve 9 is connected with the air valve 2. The measuring head 5 and the rubber bottom ring 6 ...

Embodiment 2

[0074] The rest are the same as in Embodiment 1 except that a thin layer of rubber sealing ring is provided on the bottom surface of the rubber bottom ring 6 of the present invention, and the thin layer of rubber sealing ring and the rubber bottom ring 6 are connected in a detachable manner (such as by bonding).

[0075] Simultaneously in the step (2) of the present invention, the lower part of the measuring head 5 is connected with a rubber bottom ring 6 by snap-fitting, and a thin-layer rubber sealing ring is installed on the bottom of the rubber bottom ring 6 in a detachable manner, and the lower surface of the thin-layer rubber sealing ring is the same as The surface of the concrete member 7 to be tested is in close contact. Choose a thin-layer rubber sealing ring that can be bonded on both sides. The upper surface is bonded to the bottom of the rubber bottom ring 6, and the lower surface is bonded to the surface of the concrete component 7 to be tested. The thin-layer rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com