Method for Measuring the Effective Diffusion Coefficient of Radon in Thin Films

A technology of diffusion coefficient and thin film, applied in the field of nuclear radiation detection, can solve problems such as long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

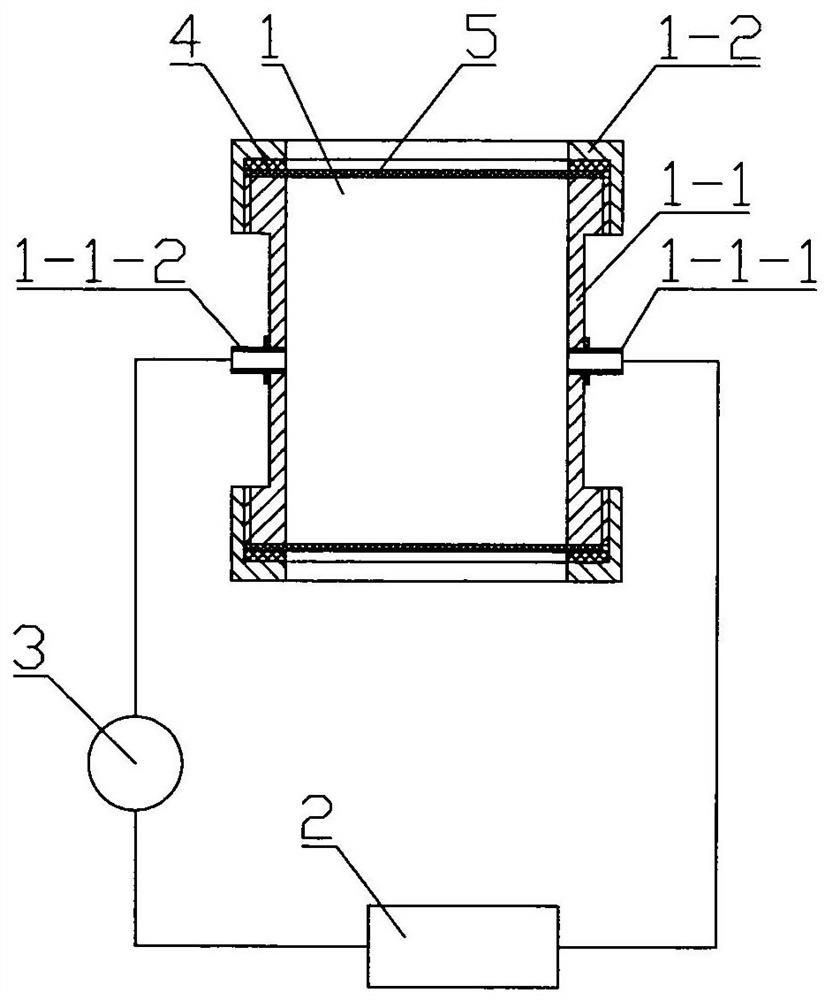

[0060] Embodiment 1. A device for measuring the effective diffusion coefficient of radon in a thin film, including a measuring chamber 1 , a radon measuring instrument 2 , a pump 3 and an annular sealing gasket 4 .

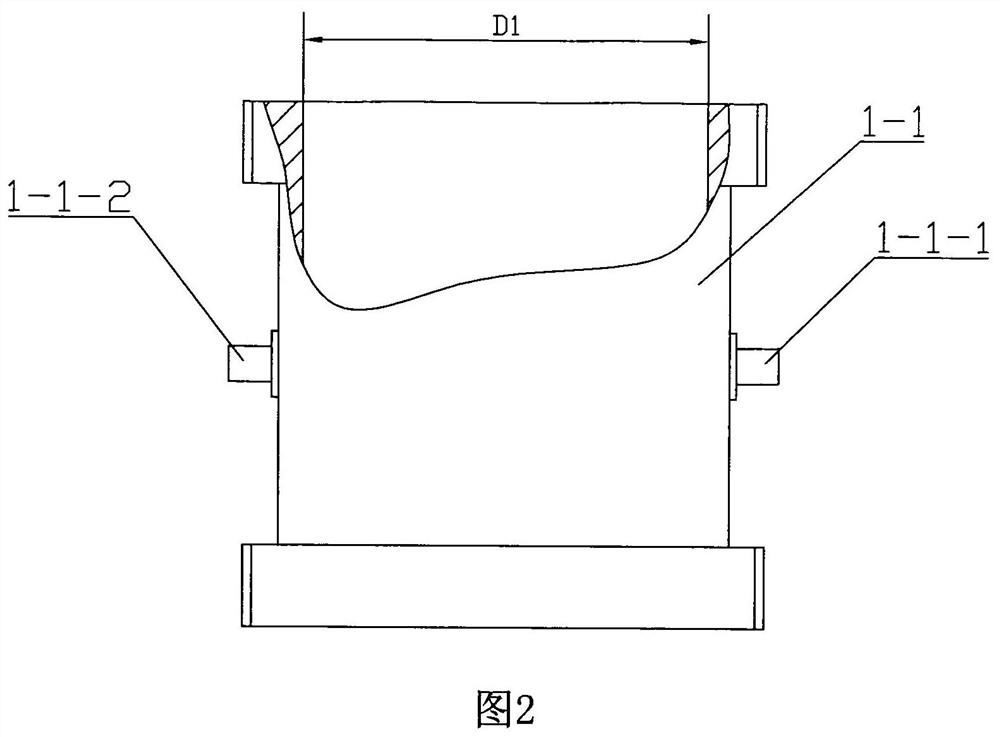

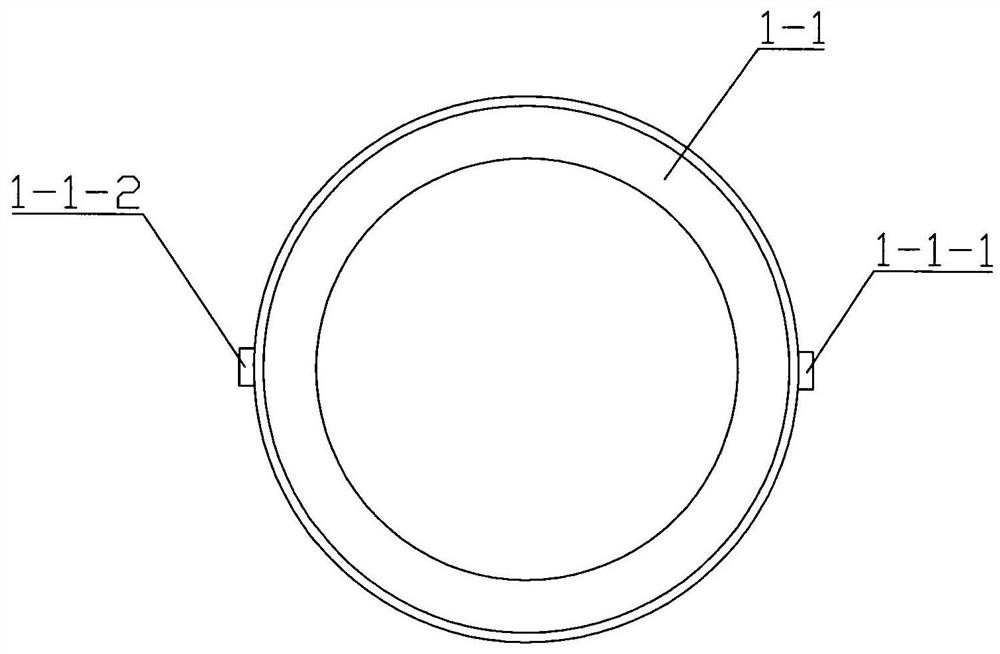

[0061] The measuring chamber 1 includes a threaded cylindrical cylinder 1-1 at both ends and threaded end caps 1-2 connected to the two ends of the cylindrical cylinder 1-1, on the wall of the cylindrical cylinder 1-1 The air outlet joint 1-1-1 and the air intake joint 1-1-2 are symmetrically arranged, the inner diameter of the cylindrical cylinder 1-1 is D1, and the threaded end cap 1-2 is provided with an annular groove 1-2- 1. An annular sealing gasket 4 is installed in the annular groove 1-2-1, and the hole diameter on the end cover plate of the threaded end cover 1-2 is D2, where D1=D2.

[0062] The gas outlet joint 1-1-1 on the measurement chamber 1 is connected to the gas inlet of the radon meter 2 through a pipeline, the gas outlet of the radon meter 2 is ...

Embodiment 2

[0088] Embodiment 2, compared with Embodiment 1, the difference is: on the cylinder wall of the cylindrical cylinder 1-1, four cylindrical measuring chambers 6 are added, and the cylindrical measuring chamber 6 is connected with the cylindrical cylinder 1-1. The inner cavity of 1 is connected, and the inner diameter of the cylindrical measuring cavity 6 is the same as that of the cylindrical barrel 1-1. The structure of the end of the cylinder body 1-1 is the same as that of the threaded end cap 1-2 connected with the cylindrical cylinder body 1-1.

[0089] The method of measuring the effective diffusion coefficient of radon in the film by using the above-mentioned measuring device through six films is as follows, which includes the measurement process and the calculation process:

[0090] 1. Measurement process:

[0091] A. Cut the film to be measured into a circular film sheet 5 with the same diameter as the outer diameter of the port of the cylindrical cylinder 1-1, and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com