Fresh siebold crabapple shelling machine

A technology of peeling machine and fresh fruit, which is applied in the field of camellia fresh fruit peeling machine, which can solve the problems affecting the peeling quality, incomplete peeling of camellia, strong seed crushing force, etc., so as to improve the quality of peeling, protect the quality and reduce damage force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

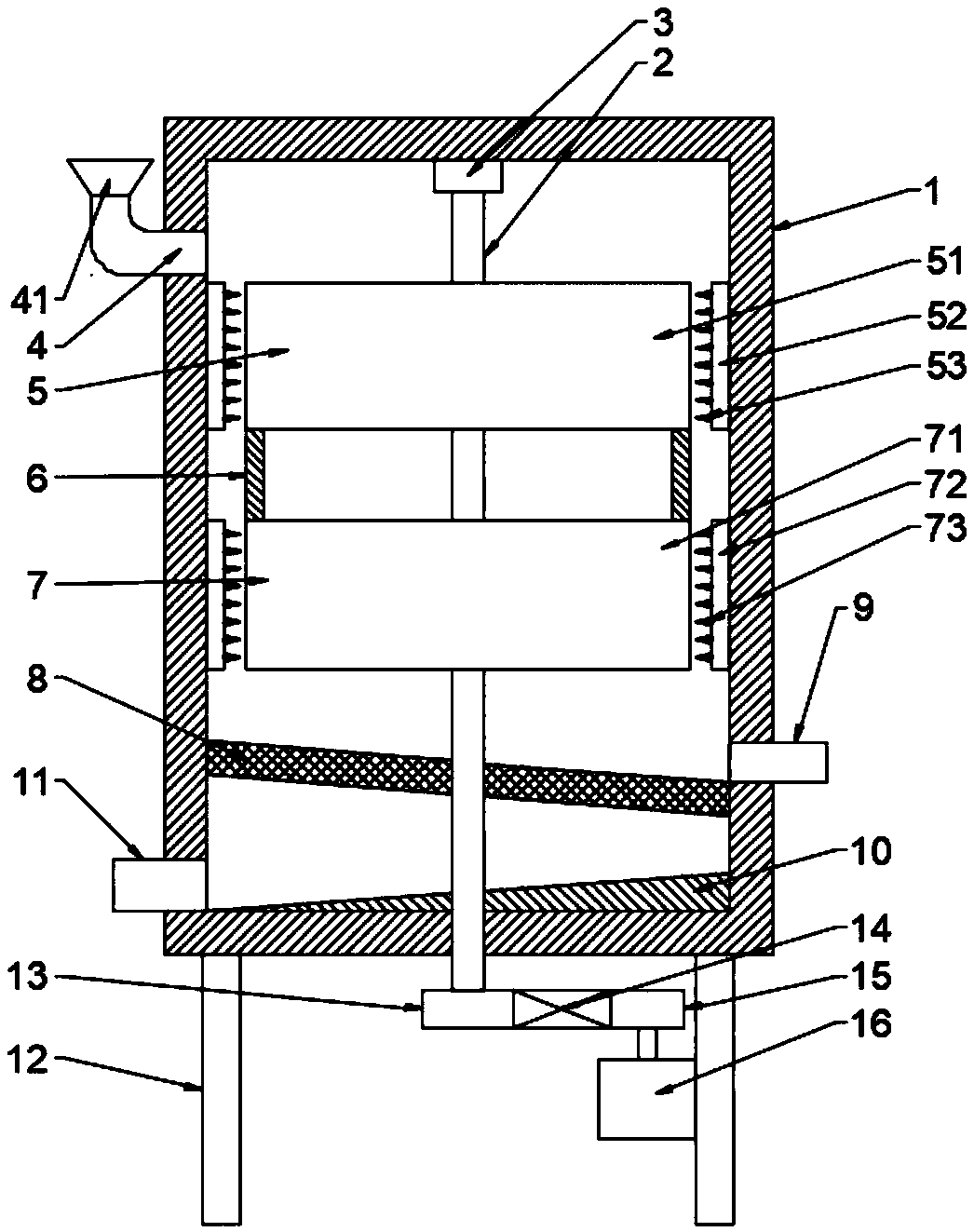

[0025] see Figure 1~3 , a camellia fresh fruit peeling machine, comprising a bracket 1, the bracket 1 is a cylindrical structure, the middle part of the inner cavity of the bracket 1 is provided with a rotating shaft 2, the axis of the bracket 1 coincides with the axis of the rotating shaft 2, and the top of the rotating shaft 2 The bearing seat 3 is rotatably connected to the inner cavity wall of the bracket 1, the bottom end of the rotating shaft 2 penetrates the inner cavity bottom wall of the bracket 1 and is fixedly connected with the driven gear 13, and the rotating shaft 2 and the bracket 1 are connected in rotation, and the rotating shaft 2 The outer circular surface of the shell is provided with the first shelling mechanism 5, the second shelling mechanism 7 and the screening device 8 in turn from top to bottom. Cooperating feed pipe 4, described feed pipe 4 is L-shaped structure, the other end of feed pipe 4 connects feed hopper 41 through, and described first peeli...

Embodiment 2

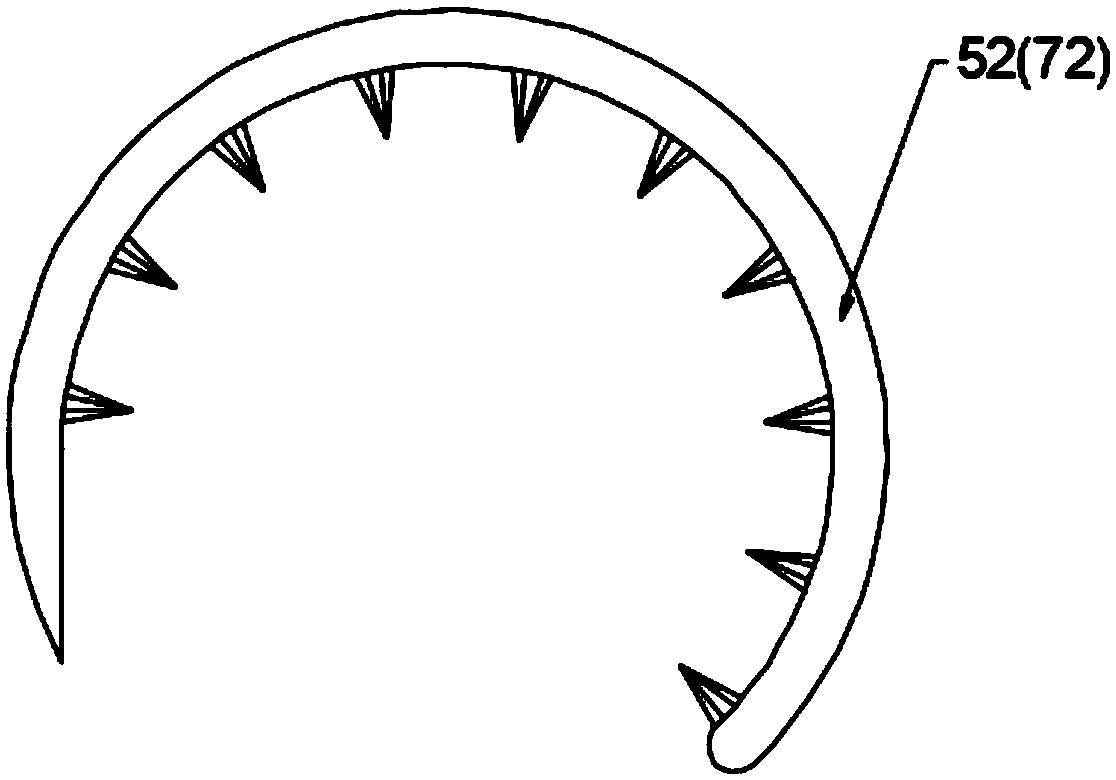

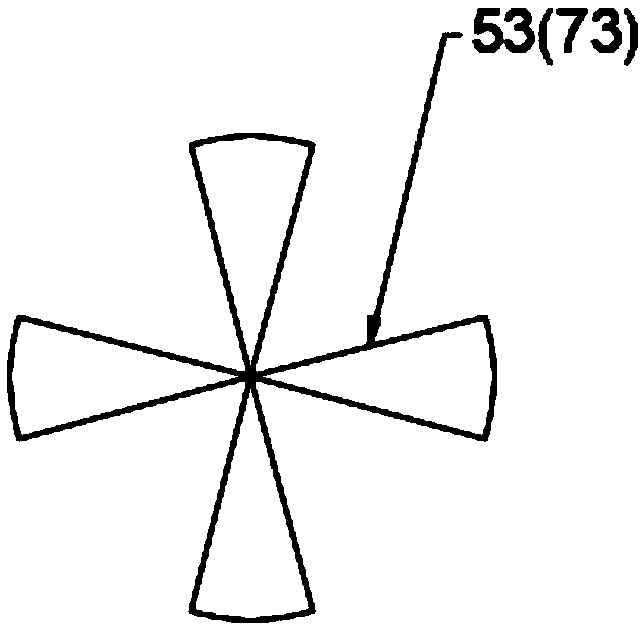

[0027] This embodiment is a further elaboration on the basis of Embodiment 1. The first peeling mechanism 5 includes a first squeeze roller 51 and a first baffle 52, and the first squeeze roller 51 is sleeved on the rotating shaft 2 The outer circular surface of the first squeeze roller 51 coincides with the axis of the rotating shaft 2. The first squeeze roller 51 is made of silica gel material. The first baffle 52 is a semi-circular structure. The first baffle 52 The first baffle plate 52 corresponds to the first squeeze roller 51 in the horizontal direction, and the inner cavity wall of the first baffle plate 52 is uniformly provided with a number of first cracking knives 53. The first cracking tool 53 is a cross-shaped structure, the distance between the outer circular surface of the first squeeze roller 51 and the inner cavity wall of the first baffle 52 is 2.5 cm to 3 cm, and the first The depth of a cracking cutter 53 is 2cm-3cm, and the effective cutting depth is 3mm-5...

Embodiment 3

[0030] This embodiment is a further elaboration on the basis of Embodiment 1. The bottom of one side end of the support 1 is connected with the seed outlet 9 matched with the screening device 8, and the bottom end of the other side end of the support 1 is penetrated. It is connected with a shell outlet 11, and the inner cavity bottom wall of the support 1 is provided with a deflector 10 matched with the shell outlet 11, and the camellia fruit shell fragments and seeds after shelling are screened by a screening device 8, The sieved seeds are discharged from the seed outlet 9, and the husk fragments screened are discharged through the husk outlet 11 under the action of the deflector 10.

[0031] The edge of the bottom end surface of the support 1 is evenly provided with a plurality of legs 12, and a motor 16 is arranged on one of the legs 12, and the motor shaft of the motor 16 is fixedly connected with a driving gear 15 matched with a driven gear 13 , the driving gear 15 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com