Novel activated carbon adsorbing material loaded with imidazole ionic liquid

A technology of activated carbon adsorption and ionic liquid, which is applied in the direction of adsorption of water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., to achieve good stability, good adsorption effect, and high heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

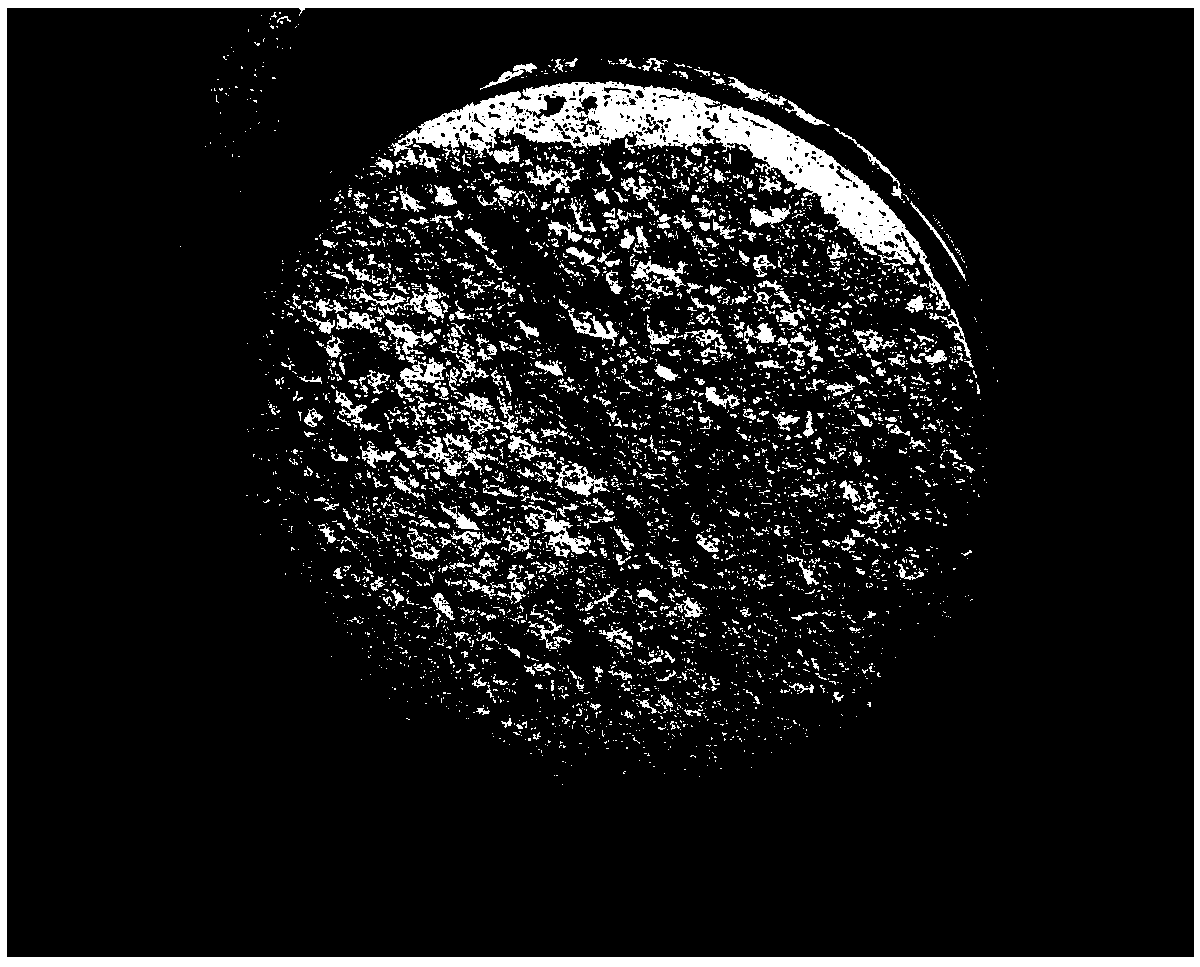

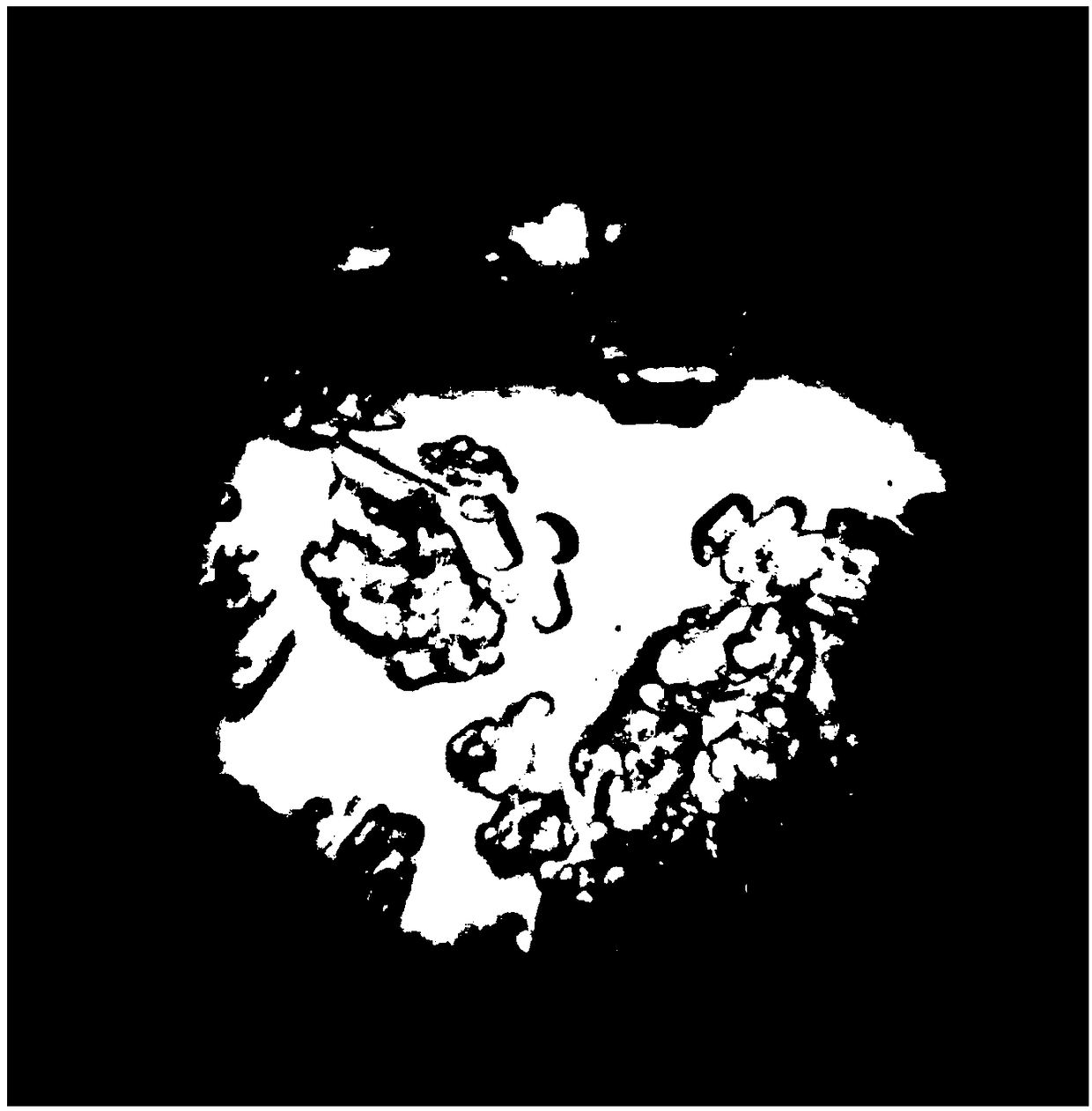

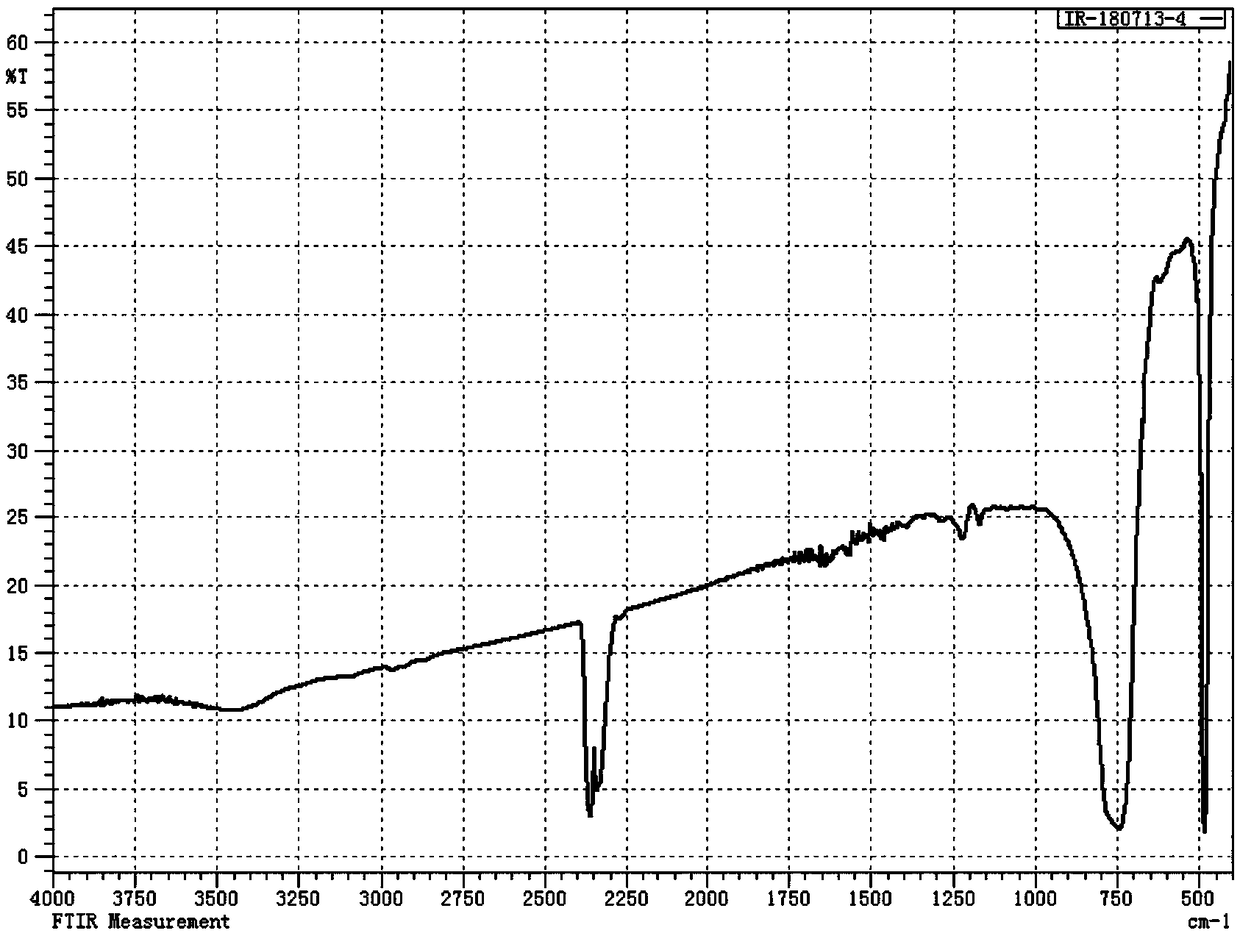

Image

Examples

Embodiment 1

[0023] A novel active carbon adsorption material loaded with ionic liquids, the specific steps are as follows:

[0024] (1) Preparation of bromo-1-hexyl-3-methylimidazolium ionic liquid

[0025] Weigh 1-methylimidazole and bromo-n-hexane in a 250mL single-necked flask according to the molar ratio of 1:1.2, and react in a constant temperature 80°C oil bath for 11 hours to obtain the intermediate bromo-1-hexyl-3-methyl Imidazole; the temperature is 70°C, the pressure is 0.5 standard atmospheric pressure and vacuum distillation to obtain purified bromo-1-hexyl-3-methylimidazole ionic liquid;

[0026] (2) Activated carbon supported ionic liquid

[0027] According to bromo 1-hexyl-3-methylimidazole ionic liquid after purification and active carbon powder mass ratio is 9.8:1, the bromo 1-hexyl-3-methylimidazole ionic liquid after purification is added active carbon powder ( Fineness ≤ 0.01mm) in a flask, magnetically stirred at a constant temperature of 88°C for 11 hours to make i...

Embodiment 2

[0029] A novel active carbon adsorption material loaded with ionic liquids, the specific steps are as follows:

[0030] (1) Preparation of bromo-1-hexyl-3-methylimidazolium ionic liquid

[0031] Weigh 1-methylimidazole and bromo-n-hexane in a 250mL single-necked flask according to the molar ratio of 1:1.2, and react in a constant temperature 90°C oil bath for 12 hours to obtain the intermediate bromo-1-hexyl-3-methyl Imidazole; the temperature is 70°C, the pressure is 0.5 standard atmospheric pressure and vacuum distillation to obtain purified bromo-1-hexyl-3-methylimidazole ionic liquid;

[0032] (2) Activated carbon supported ionic liquid

[0033] According to bromo 1-hexyl-3-methylimidazole ionic liquid after purification and active carbon powder mass ratio is 9.5:1, the bromo 1-hexyl-3-methylimidazole ionic liquid after purification is added active carbon powder in In the flask, magnetically stir at a constant temperature of 85°C for 12 hours to make it evenly mixed, and...

Embodiment 3

[0035] A novel active carbon adsorption material loaded with ionic liquids, the specific steps are as follows:

[0036] (1) Preparation of bromo-1-hexyl-3-methylimidazolium ionic liquid

[0037] Weigh 1-methylimidazole and bromo-n-hexane in a 250mL single-necked flask according to the molar ratio of 1:1.2, and react in a constant temperature 85°C oil bath for 10 hours to obtain the intermediate bromo-1-hexyl-3-methyl Imidazole; the temperature is 70°C, the pressure is 0.5 standard atmospheric pressure and vacuum distillation to obtain purified bromo-1-hexyl-3-methylimidazole ionic liquid;

[0038] (2) Activated carbon supported ionic liquid

[0039] According to bromo 1-hexyl-3-methylimidazole ionic liquid after purification and active carbon powder mass ratio is 10:1, the bromo 1-hexyl-3-methylimidazole ionic liquid after purification is added active carbon powder finely degree ≤ 0.01mm) in a flask, magnetically stirred at a constant temperature of 90°C for 10 hours to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com