Modularized movable multi-layer stacking, steaming and curing production system for PC components and production method

A production system and mobile technology, applied in ceramic molding workshops, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of large steam curing kiln, small production volume and high energy consumption, and achieve the improvement of steam curing efficiency, The effect of reducing indirect costs and saving energy resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A modular mobile multi-layer stacking steaming and curing PC component production system, which consists of: a steaming and curing shed 1, characterized in that: the steaming and curing shed is a linear closed space, and the steaming and curing shed is set to be openable Shed door 4, a plurality of parallel mould table moving lines 2 are covered in the steaming and curing shed, the covered moving lines of the moulding table extend out or run through the steaming and curing shed, and a ferry car is arranged outside the steaming and curing shed Walking track, the moving line of the mold table is vertical to the traveling track 10 of the ferry car, and the ferry car 3 travels on the track of the ferry car. The moving line of the mold table includes two rows of ground wheels 5 arranged in a straight line and a drive motor 6. The ground wheel supports the mold table 7 made of prefabricated components. The distance between the ground wheels ensures that the prefabricated compo...

Embodiment 2

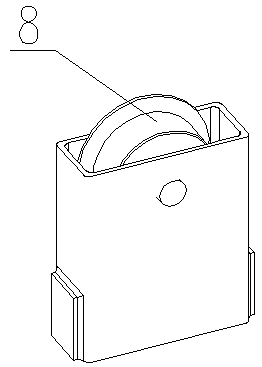

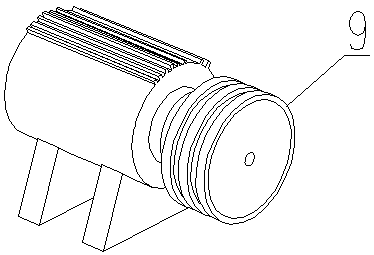

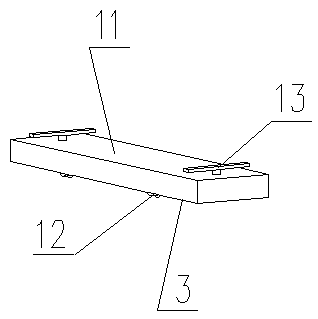

[0034]According to the modular mobile multi-layer stacking steam curing PC component production system described in Embodiment 1, the ground wheel and the drive motor are installed on the foundation, and the wheel 8 is provided on the top of the ground wheel support frame, The wheel rotates 360 degrees along its own central axis, the driving motor is arranged between the ground wheels, the driving motor is arranged in a cross between the two rows of ground wheels, the driving motor wheel has a friction surface 9, and the driving motor wheel has a friction surface 9. The mold table continuously contacts the driving motor during the advancing process, providing forward driving force for the mold table; the ferry car has a frame body 11, the bottom of the frame body is provided with a traveling wheel 12, and the traveling wheel is provided with a driving device, The top of the frame body is provided with a jacking device 13, and the jacking device can be lifted and lowered. The mo...

Embodiment 3

[0036] According to the modular mobile multi-layer stacking steam curing PC component production system described in Embodiment 1 or 2, the steam curing shed outer mold table moving line provides cleaning stations, scribing stations, Form support station, brushing release agent station, tie-bar station, pre-embedded parts setting station, concrete placing station, vibrating station, post-processing station, mold removal and lifting station, and mold table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com