Intermediate glaze used for ceramic

A ceramic and range technology, applied in the field of ceramic glaze, can solve the problems of high defective product rate, poor melting performance, difficult to combine, etc., and achieve the effect of no accumulation of glaze, smooth glaze surface and high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] SiO 2 : 51.0, Al 2 o 3 : 7.8, K 2 O: 5.5, Na 2 O: 1.9, CaO: 10.4, MgO: 1.8, P 2 o 5 : 0.9, B 2 o 3 : 1.4, ZnO: 9.0, ZrO 2 : 9.5.

Embodiment 2

[0026] SiO 2 : 51.5, Al 2 o 3 : 8.0, K 2 O: 5.7, Na 2 O: 2.0, CaO: 10.6, MgO: 2.0, P 2 o 5 : 1.1, B 2 o 3 : 1.5, ZnO: 9.1, ZrO 2 : 9.7.

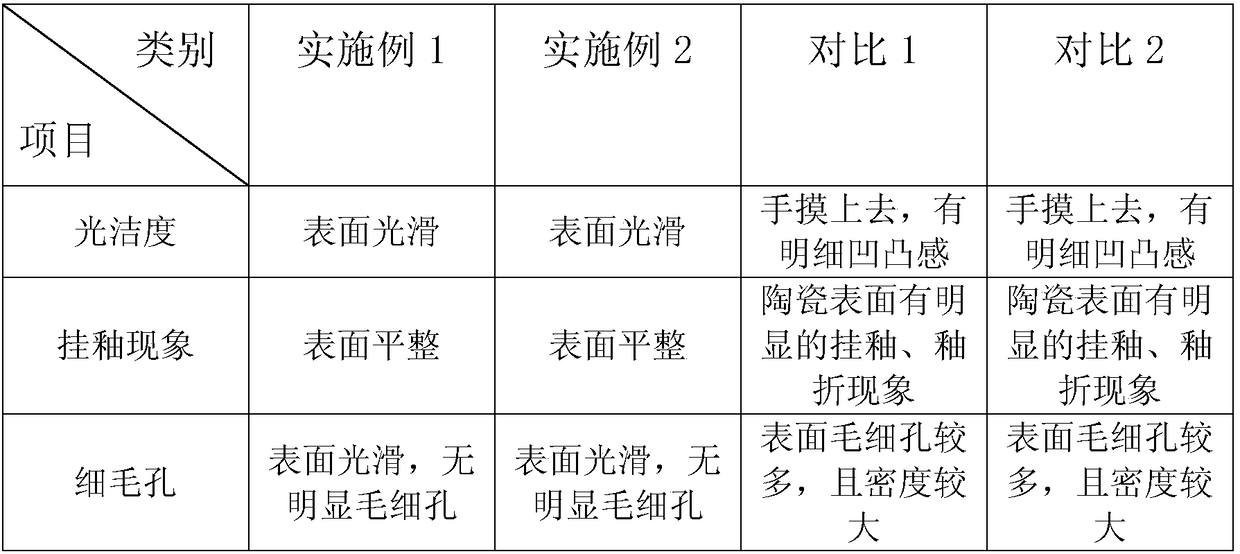

[0027] In order to better highlight the beneficial effects of the present invention, two different intermediate glazes are purchased on the market at will, and applied to the ceramic surface respectively. After testing and comparing, the superior effect of the present invention is shown.

[0028] Select two different intermediate glazes from Example 1 and Example 2 respectively and apply them on the ceramic surface, and in the application process, ensure that the concentration of the intermediate glaze reaches 68°~72°Be during glazing, and when glazing, its calcining temperature The temperature range is from 1120°C to 1150°C; and two kinds of intermediate glazes on the market are randomly selected, and the glaze is applied to the surface of the ceramic according to the existing processing method on the market, and then the ceramic pot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com