Environment-friendly nano aqueous dry powder coating and preparation method thereof

A technology of dry powder coating and nano-water, which is applied in the direction of powder coating and coating, which can solve the problems of few types of water-based coatings and difficult development, and achieve the effects of easy transportation and storage, low raw material cost and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

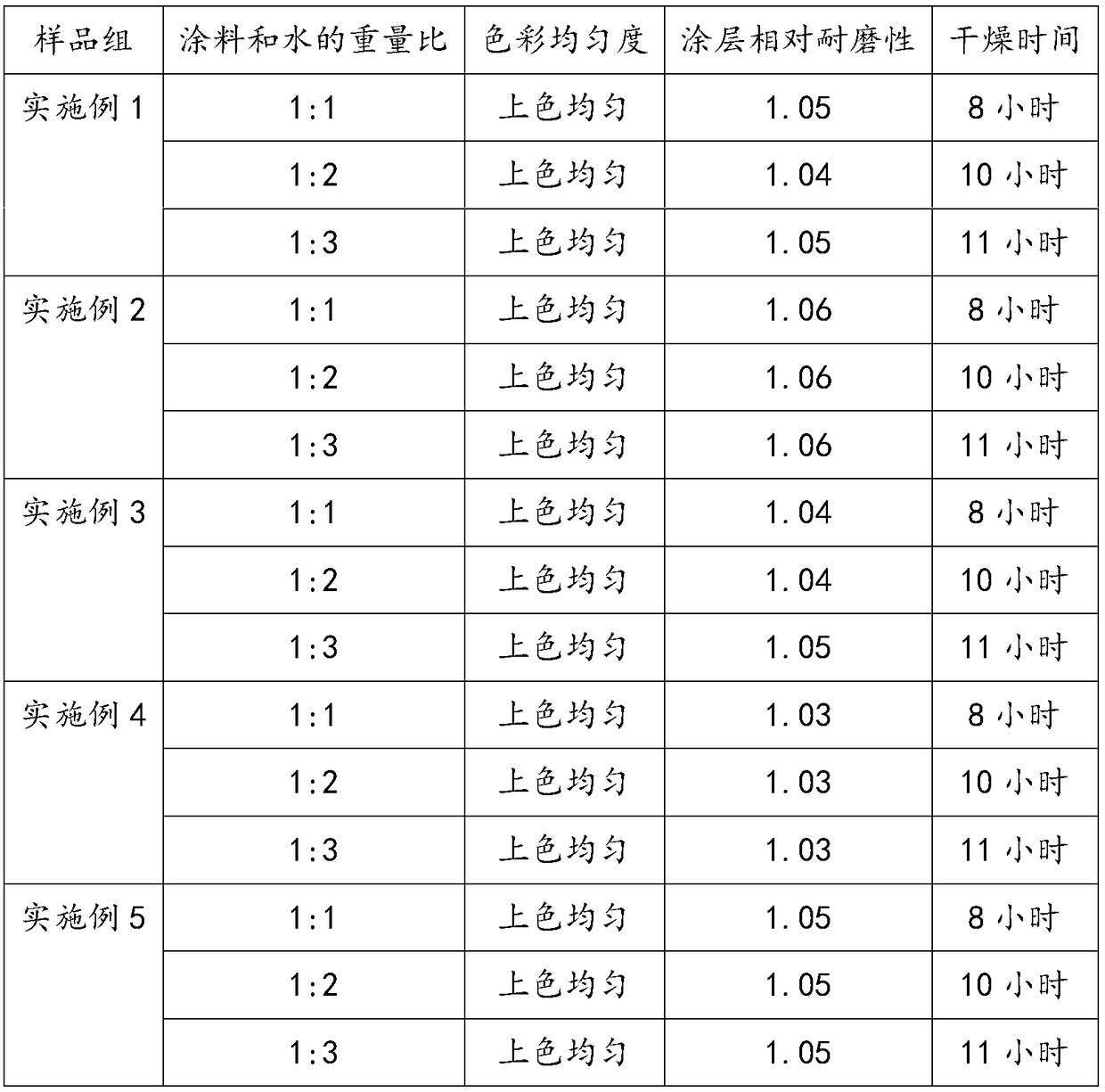

Examples

Embodiment 1

[0017] Prepare silver-white nano water-based dry powder coating, the process is as follows:

[0018] (1) 5g of nanoscale resin base powder and 5g of silver-white nanoscale pigment powder are mixed uniformly in a mixing device;

[0019] (2) Heat the uniformly mixed powder in a microwave device to 50-55°C and keep it warm for 2 hours;

[0020] (3) Transfer the mixed powder out of the microwave device and evenly mix in 1g nano-graphene powder, then place it in the microwave device and heat it to 45-50°C, and keep it warm for 2 hours;

[0021] (4) Transfer the mixed powder out of the microwave device, cool naturally to room temperature, and evenly mix in 10 g of nano-sized polymethacrylic acid powder to obtain a silver-white nano-scale water-based dry powder coating.

Embodiment 2

[0023] Prepare silver-white nano water-based dry powder coating, the process is as follows:

[0024] (1) 5g of nanoscale resin base powder and 5g of silver-white nanoscale pigment powder are mixed uniformly in a mixing device;

[0025] (2) Heat the uniformly mixed powder in a microwave device to 50-55°C and keep it warm for 2 hours;

[0026] (3) Transfer the mixed powder out of the microwave device and evenly mix in 2g nano-graphene powder, then place it in the microwave device and heat it to 45-50°C, and keep it warm for 2 hours;

[0027] (4) Transfer the mixed powder out of the microwave device, cool naturally to room temperature, and evenly mix in 10 g of nano-sized polymethacrylic acid powder to obtain a silver-white nano-scale water-based dry powder coating.

Embodiment 3

[0029] Prepare silver-white nano water-based dry powder coating, the process is as follows:

[0030] (1) 5g of nanoscale resin base powder and 5g of silver-white nanoscale pigment powder are mixed uniformly in a mixing device;

[0031] (2) Heat the uniformly mixed powder in a microwave device to 50-55°C and keep it warm for 2 hours;

[0032] (3) Transfer the mixed powder out of the microwave device and evenly mix in 1g nano-graphene powder, then place it in the microwave device and heat it to 45-50°C, and keep it warm for 2 hours;

[0033] (4) The mixed powder is transferred out from the microwave device, and after being naturally cooled to room temperature, 15 g of nano-sized polymethacrylic acid powder is evenly mixed in to obtain a silver-white nano-scale water-based dry powder coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com