Impurity removing device of medium-frequency induction smelting furnace and impurity removing method

An induction melting furnace and intermediate frequency technology, which is applied in the field of impurity removal devices of intermediate frequency induction melting furnaces, can solve the problems of affecting the impurity removal effect, slowing down the reaction speed, and reducing the reaction power, and achieves the improvement of the impurity removal effect and the impurity precipitation ability. Enhance and improve the effect of kinetic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

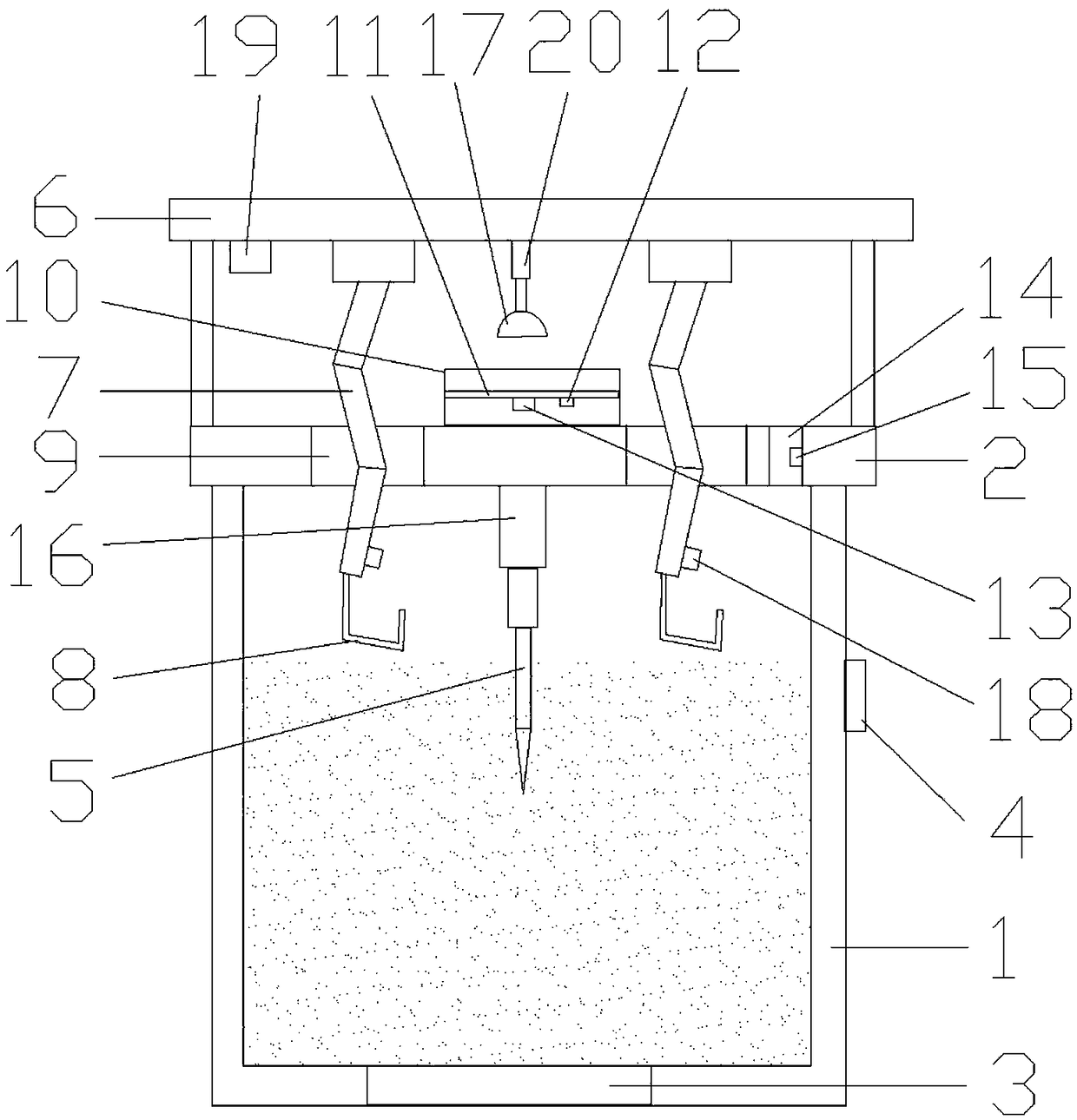

[0037]An impurity removal device for an intermediate frequency induction melting furnace, comprising a furnace body 1 and an upper cover 2 arranged on the furnace body 1, an argon blowing module 3 with an adjustable flow rate is provided at the bottom of the furnace body 1, and the furnace body 1 There is a vibration intensity detection module 4 for detecting the rolling degree of molten steel, the vibration intensity detection module 4 can be arranged in the furnace body 1 or outside the furnace body 1, and it is arranged outside the furnace body 1 in this embodiment. The middle position of the bottom of the upper cover 2 is provided with an ultrasonic vibrating module 5 with adjustable power for ultrasonic cavitation of molten steel to precipitate impurities, and the top of the upper cover 2 is provided with a solid inclusion removal and transfer module and a solid The inclusion analysis module, the solid inclusion fishing and transfer module includes a support 6 arranged on ...

Embodiment 2

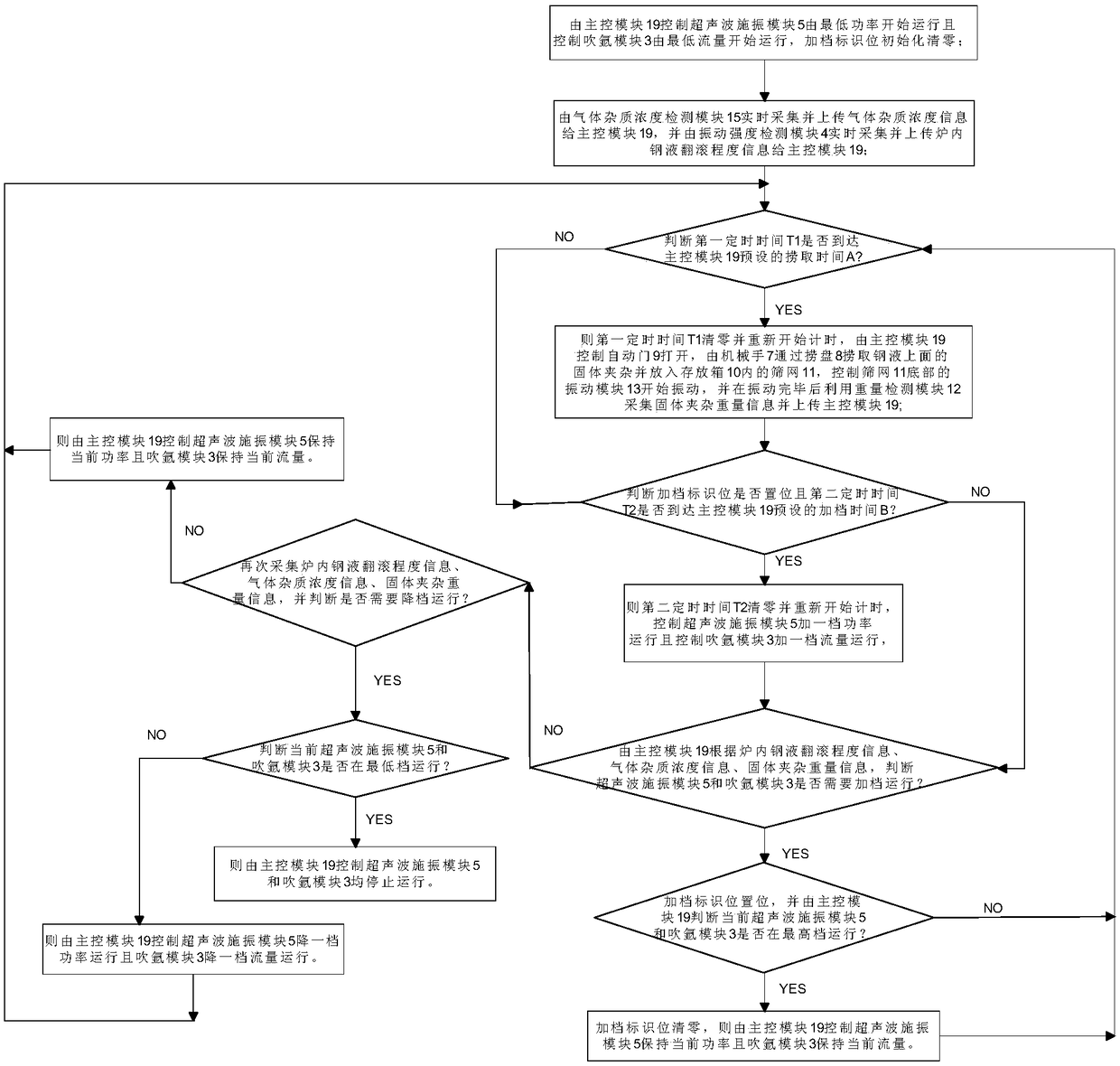

[0043] A method for removing impurities of an intermediate frequency induction melting furnace, based on the impurity removal device of the intermediate frequency induction melting furnace of embodiment 1, the method comprises the following steps:

[0044] (1) The main control module 19 controls the ultrasonic vibration application module 5 to start running from the lowest power and controls the argon blowing module 3 to start running from the lowest flow rate, and the gear-up flag is initialized and cleared;

[0045] (2) Gather in real time by the gas impurity concentration detection module 15 and upload the gas impurity concentration information to the main control module 19, and collect in real time by the vibration intensity detection module 4 and upload the molten steel tumbling degree information in the furnace to the main control module 19;

[0046] (3) Determine whether the first timing time T1 reaches the fishing time A preset by the main control module 19 ?

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com