Color-changing fiber

A color-changing fiber and fiber technology, which is applied to the chemical characteristics of fibers, conjugated synthetic polymer artificial filaments, textiles and papermaking, etc., can solve the problems of affecting the overall layout of the room, fabric heating, and low environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of described polymethyl methacrylate modified photochromic agent, comprises the following steps:

[0030] 1) Adding methyl methacrylate monomer and ethanol into the reactor, after stirring, the methyl methacrylate is completely dissolved in ethanol, adding an inorganic discoloration agent, continuing to stir and raising the temperature to 60°C-80°C, Then add the initiator BPO ethanol solution, stop heating and keep stirring for 1-2 hours, and gradually cool into a solid;

[0031] 2) Grinding the above solid into powder to obtain a polymethyl methacrylate modified photochromic agent.

[0032] The polymethyl methacrylate modified photochromic agent is a shell-core structure with the photochromic agent as the core and a polymethyl methacrylate shell. The shell-core structure can ensure the stability with the polymer fiber. Combine and distribute evenly.

Embodiment 1

[0034] A color-changing fiber, in which at least light-changing fibers are included;

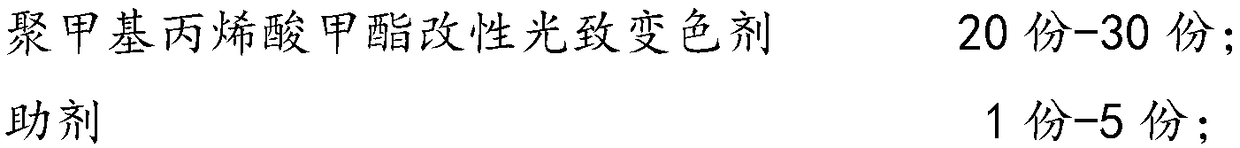

[0035] Photochromic fiber by weight, it consists of:

[0036]

[0037] The inorganic photochromic agent among them is CaHfO3: La 2 o 3 .

[0038] In the polymethyl methacrylate modified photochromic agent, the photochromic agent accounts for 0.1% of the total weight of the polymethyl methacrylate modified photochromic agent.

[0039] The auxiliary agent includes one or more combinations of oxidizing agent, compatibilizer, antiaging agent and light stabilizer.

[0040] The preparation method of described polymethyl methacrylate modified photochromic agent, comprises the following steps:

[0041] 1) Add methyl methacrylate monomer and ethanol into the reactor, after stirring, the methyl methacrylate is completely dissolved in ethanol, add an inorganic discoloration agent, continue to stir and heat up to 60°C, then add trigger Agent BPO ethanol solution, stop heating and continue to kee...

Embodiment 2

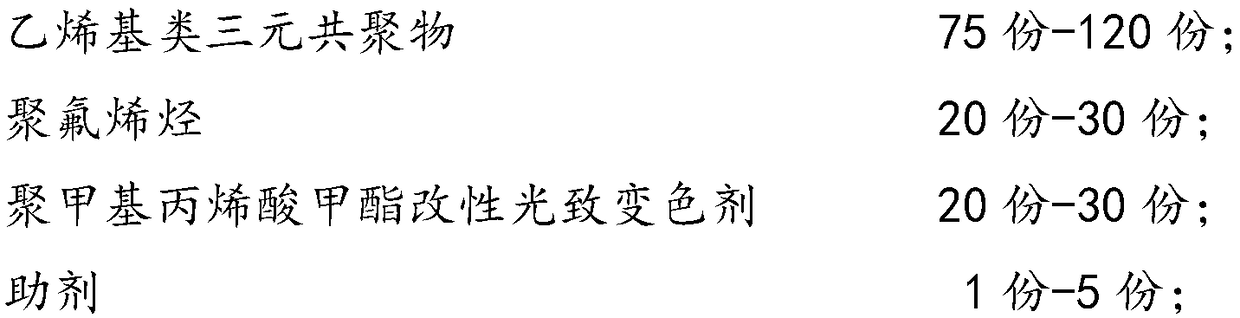

[0044] A color-changing fiber, in which at least light-changing fibers are included;

[0045] Photochromic fiber by weight, it consists of:

[0046]

[0047]

[0048] The inorganic photochromic agent among them is CaHfO3: La 2 o 3 .

[0049] In the polymethyl methacrylate modified photochromic agent, the photochromic agent accounts for 5% of the total weight of the polymethyl methacrylate modified photochromic agent.

[0050] The auxiliary agent includes one or more combinations of oxidizing agent, compatibilizer, antiaging agent and light stabilizer.

[0051] The preparation method of described polymethyl methacrylate modified photochromic agent, comprises the following steps:

[0052] 1) Add methyl methacrylate monomer and ethanol into the reactor, after stirring, the methyl methacrylate is completely dissolved in ethanol, add an inorganic discoloration agent, continue to stir and heat up to 80°C, then add trigger Agent BPO ethanol solution, stop heating and conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com